Combined piezoelectric and booster electromagnetic gas injection device

A technology of injection device and booster solenoid valve, which is applied to oil supply device, charging system, combustion engine, etc., can solve the problems of reduced gas injection pressure and injection rate, affecting the working stability of the injection device, and limited matching engine power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in more detail below in conjunction with accompanying drawing example:

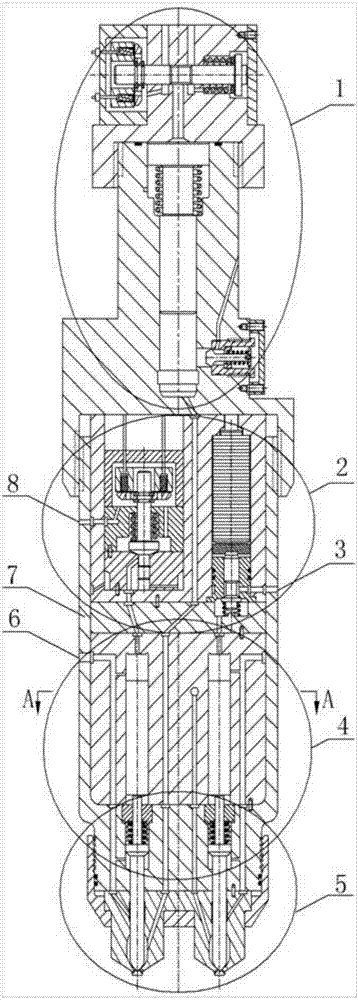

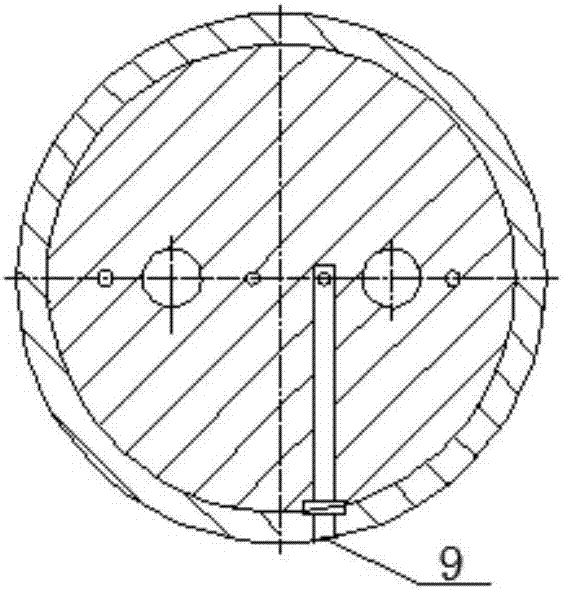

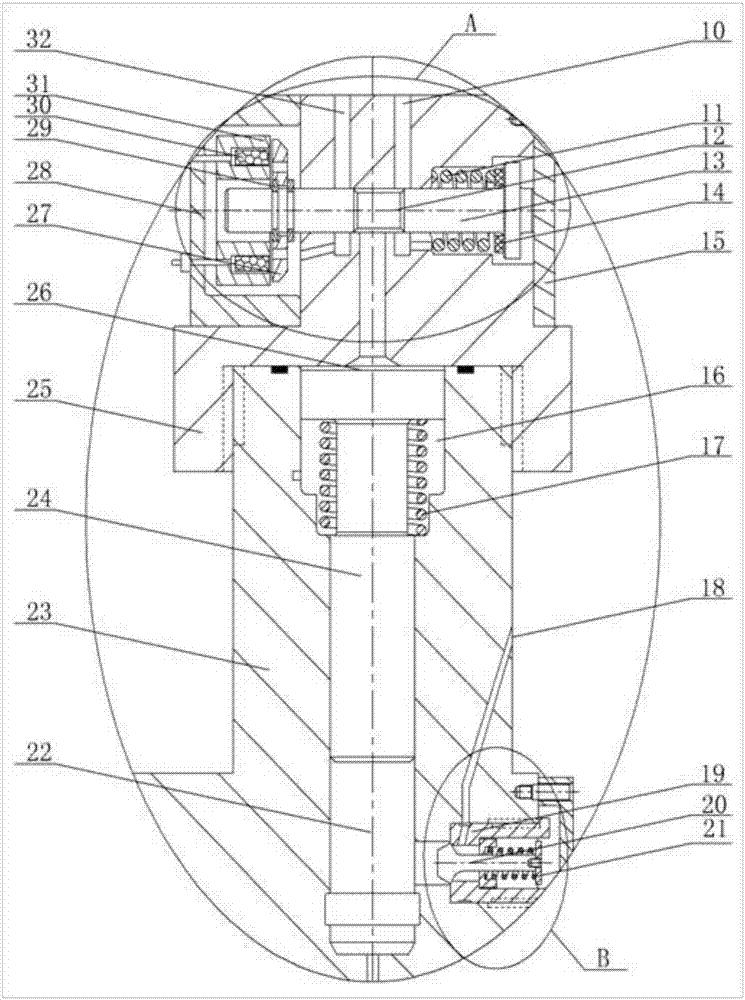

[0029] The combined piezoelectric-supercharged electromagnetic gas injection device of the present invention is mainly composed of a booster part 1, an electromagnetic-piezoelectric control part 2, a double-piston part 4, a double-needle valve nozzle part 5 and an injection device body 7. The injection device body 7 has a first low-pressure oil drain port 3, a control oil inlet 6, a second low-pressure oil drain port 8, a gas inlet 9, etc. The top view of the oil passage at the gas inlet is shown in Figure 1(b).

[0030] The pressurized part 1 is located above the injection device body 7, and the two are connected by threads. The booster part 1 mainly includes a solenoid valve A, an intake valve B, a booster piston spring 17, a booster piston sleeve 23, a booster piston 24, a solenoid valve seat 25, and the like. Wherein, solenoid valve A is composed of solenoid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com