Reinforcing method of concrete column

A concrete column and concrete technology, which is applied in building maintenance, construction, building construction, etc., can solve problems such as inability to coordinate force, and achieve the effects of saving reinforcement materials, good mechanical properties, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

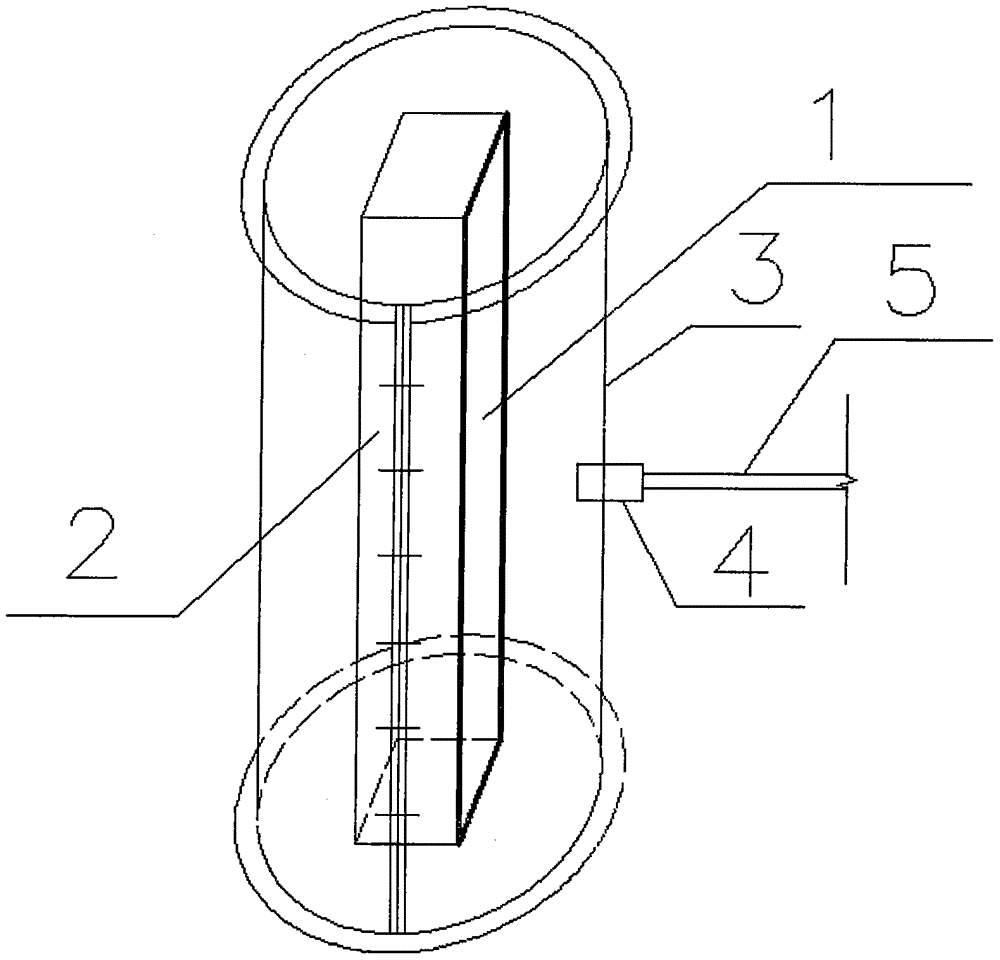

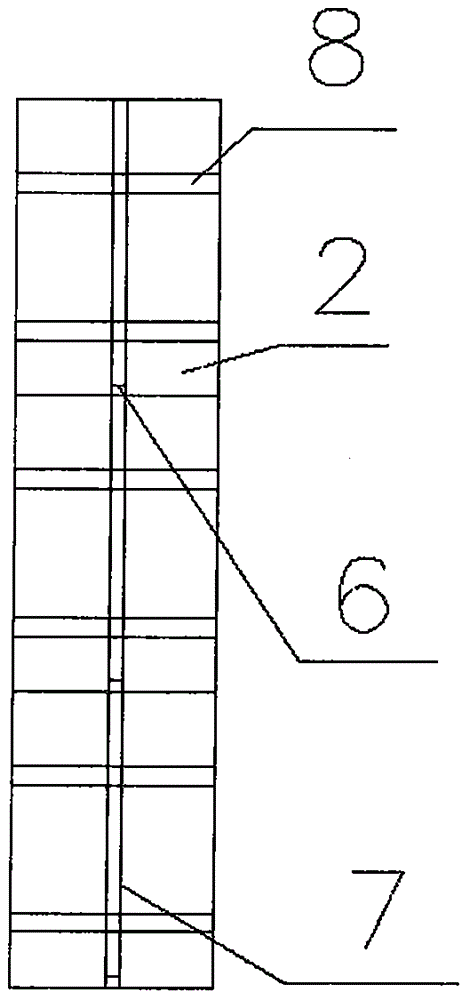

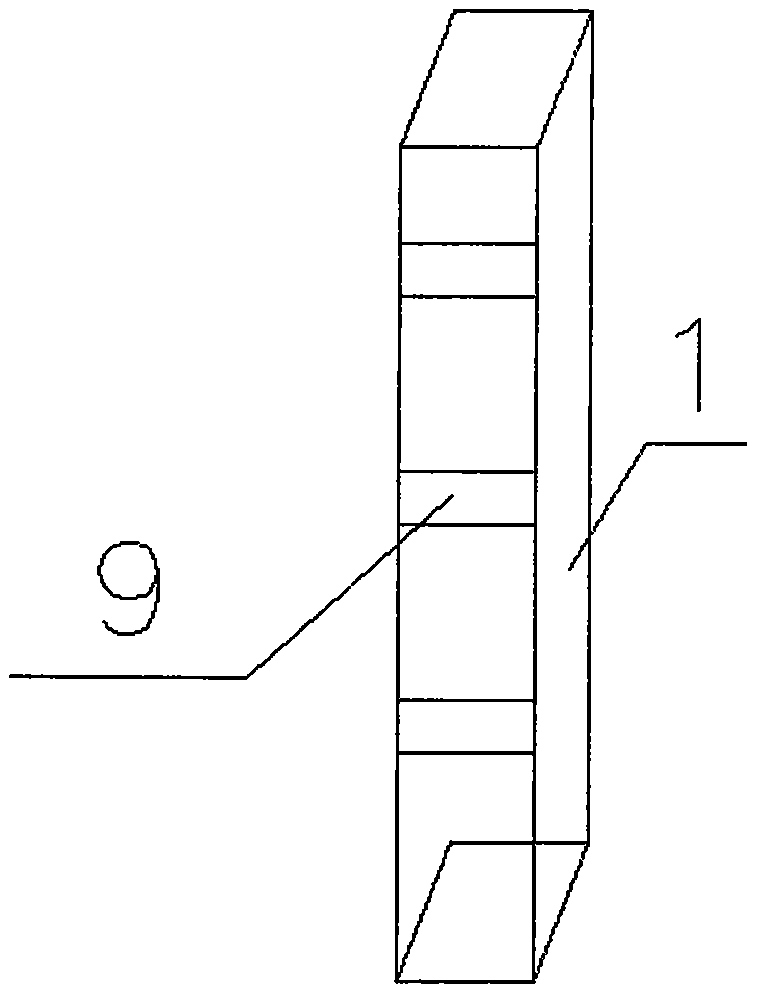

[0026] figure 1 Schematic diagram of the forming structure for the reinforcement member, figure 2 Schematic diagram for wooden formwork supports, image 3 It is a schematic diagram of the reinforced structure.

[0027] In the embodiment, the steel plate 1 is installed on two opposite sides of the concrete column. The thickness of the steel plate 1 is 12mm. The other two sides of the steel plate 1 adopt the steel plate 9, the thickness of the steel plate 9 is 14mm, and the width of the steel plate 9 is 18cm. The spacing between the steel panels 9 is 60cm, the steel panels 9 are welded to the reinforced steel plate 1, and the two opposite side steel plates 1 are connected into a whole, and the post-cast concrete is pre-pressed by a pressurizing device during the concrete pouring process; The formwork support method before pouring concrete is as follows: the two opposite sides of the concrete column install steel plate 1 directly as the formwork for pouring concrete, and the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com