Beam and side column connecting piece for prefabricated building

A prefabricated, connecting piece technology, applied in construction, building construction, etc., can solve the problems of prolonged construction period, unsuitable profiles, waste of resources, etc., and achieve the effect of improving work efficiency, high structural strength, and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

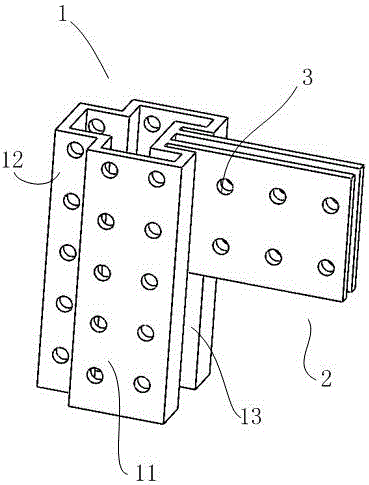

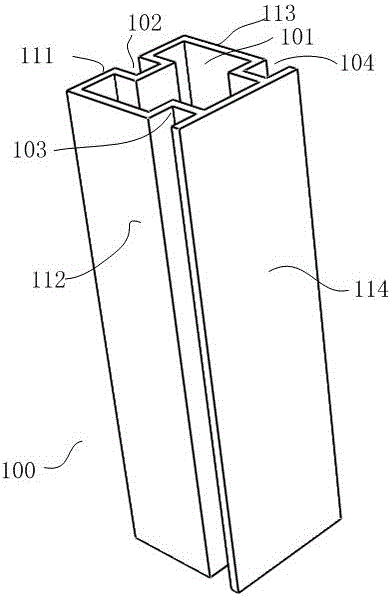

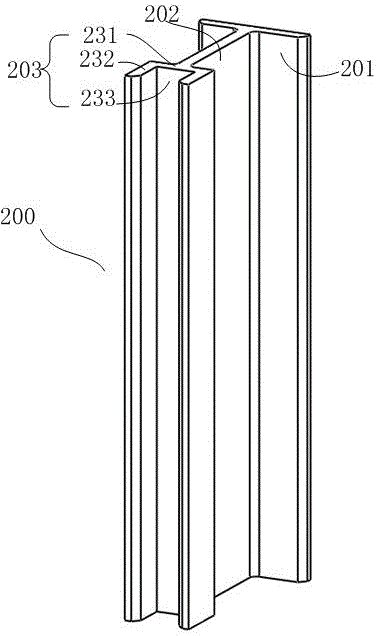

[0012] A prefabricated house beam and side column connector, including polygonal steel 1 that can be inserted into the inner cavity of side column profile 100, and two wing plates 2 that can be inserted by web 202 of beam profile 200. The polygonal steel 1 includes Two side plates 11, an outwardly protruding convex plate 12, and an inwardly recessed concave plate 13, the wing plate 2 is solidly integrated with the concave plate 13 in the groove of the concave plate; The center of its top edge 111 of the column profile 100 is provided with a first gap 102 that can accommodate the insertion of the prefabricated wall body, and the second gap 103 and the second gap 103 that can accommodate the insertion of the prefabricated wall body are provided at both ends of the side edges 112 and 113 near the bottom edge 114. Three gaps 104, the top edge, two sides and the bottom edge are maintained to form a closed cavity 101; the beam profile 200 includes an upper cornice 201, a web 202 conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com