Beam and center post connecting piece for prefabricated building

A prefabricated and connecting technology, which is applied in the direction of construction and building construction, can solve the problems of extended construction period, waste of resources, unsuitable profiles, etc., and achieve the effects of improved work efficiency, simple assembly, and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

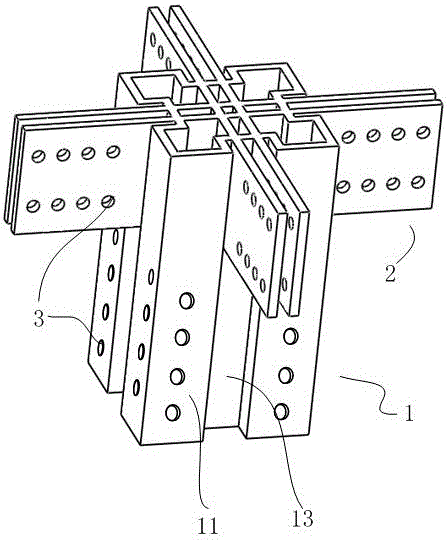

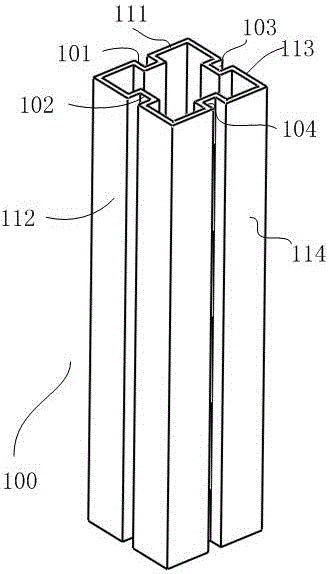

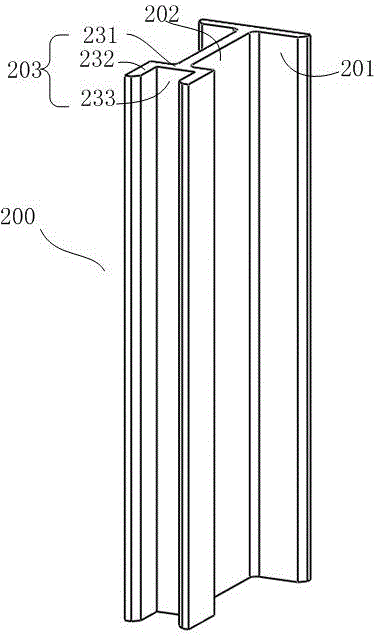

[0012] A prefabricated house beam and center column connector, including a polygonal steel 1 that can be inserted into the inner cavity of the center column profile 100, two wing plates 2 that can be inserted by the web 202 of the beam profile 200, the polygonal steel 1 and the wing plate 2 There are several connection holes 3 evenly on the top, the polygonal shaped steel 1 includes four side plates 11, the middle part of the side plates is provided with an inwardly recessed groove 13, and the wing plate 2 is connected to the side plate in the groove. 13 is solid as a whole; the profile length of the cross-section of the central column profile 100 is equal to the profile width, and the center of its top edge 111 is provided with a first gap 101 that can accommodate the insertion of a prefabricated wall body, and the left side 112 The center is provided with a second gap 102 that can accommodate the insertion of the prefabricated wall, the center of the right side 113 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com