Centrifugal test model for verifying combined action of supporting structure and soil body and manufacturing method of centrifugal test model

A technology of co-action and support structure, applied in the test of basic structure, basic structure engineering, construction, etc., can solve the problems that cannot meet the design and construction requirements, and achieve the effect of easy promotion and implementation, simple and clear principle, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing of description and specific embodiment:

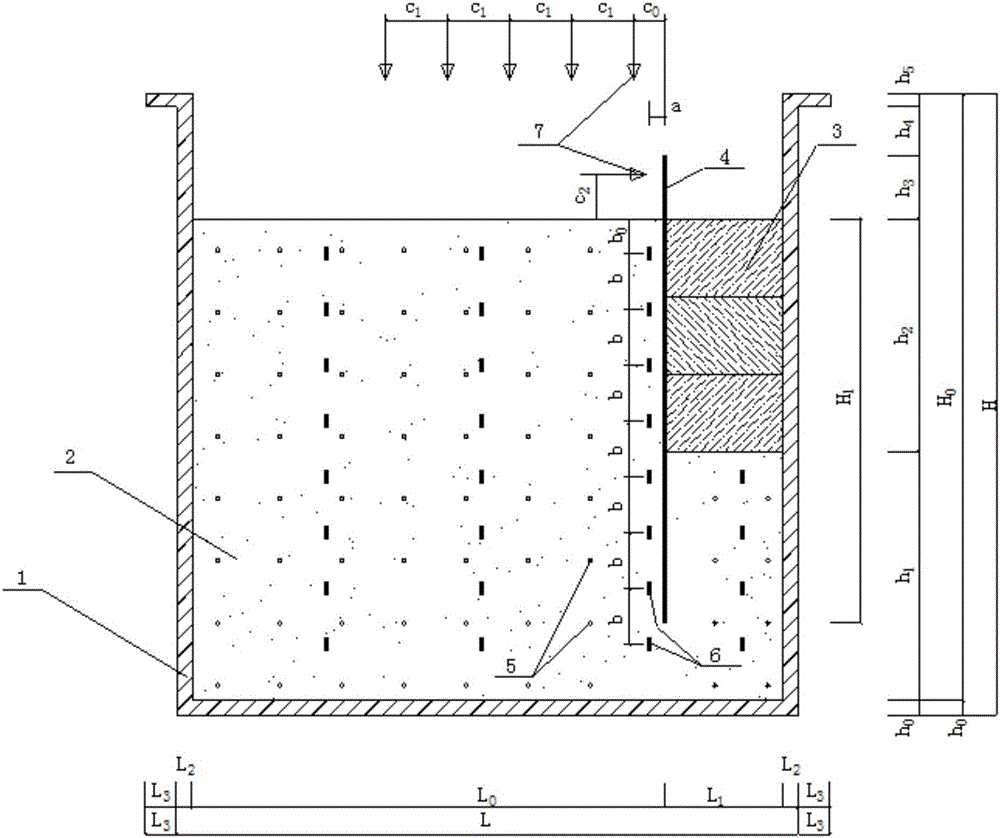

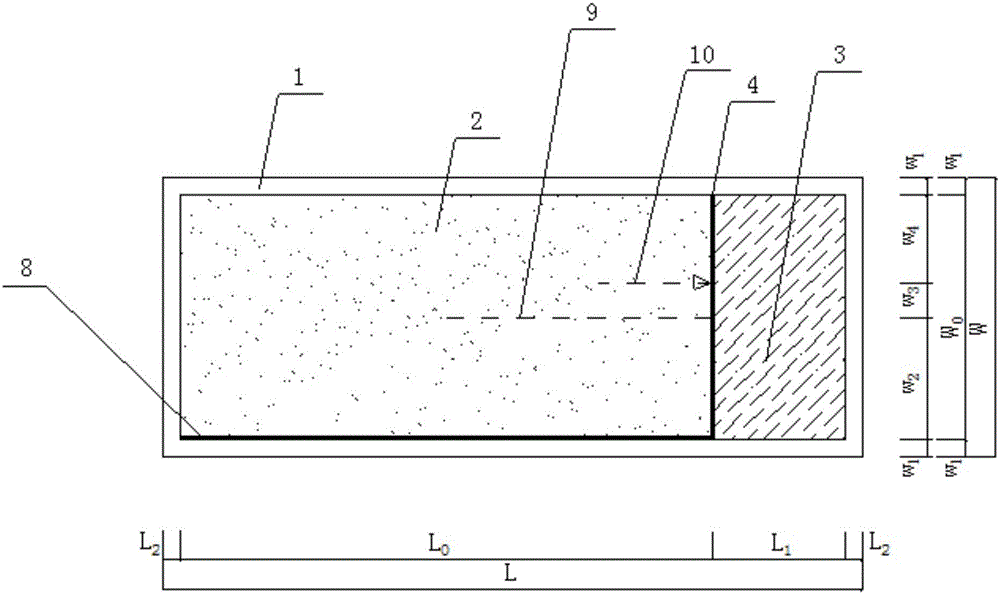

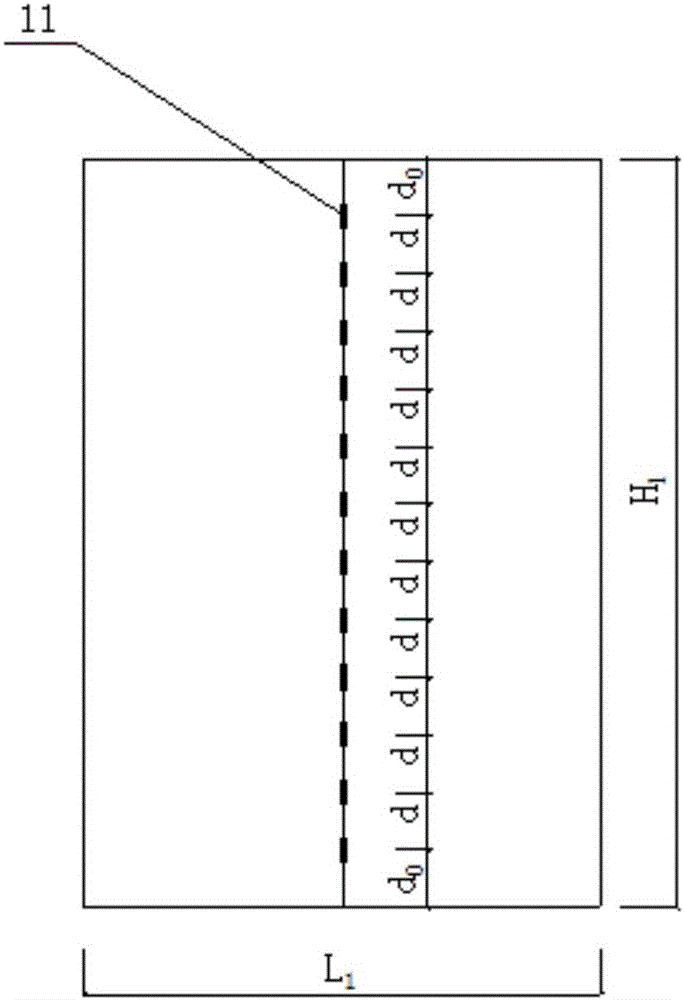

[0034] Such as figure 1 shown. The centrifugal test model for verifying the interaction between the support structure and the soil body includes a model box 1 with an open top, and a support plate 4 for simulating a support wall is vertically embedded in the model box 1, and a support plate 4 is placed on the support plate 4. A bending moment strain gauge 11 is provided to detect the bending moment strain value of the support plate 4; the support plate 4 divides the interior of the model box 1 into a foundation soil layer area and an excavation area, and the foundation soil layer area is filled with Foundation soil 2, the lower part of the excavation area is foundation soil 2, and the upper part of the excavation area is a bucket soil bag 3 for simulating bucket earthwork; an earth pressure sensor 6 is arranged in the foundation soil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com