Assembled type foundation pit supporting and protecting structure system based on prefabricated members

A technology of prefabricated components and foundation pit support, applied in infrastructure engineering, protection devices, buildings, etc., can solve pollution, resource waste and environmental problems, and achieve the effects of reducing construction waste, good economic and environmental benefits, and convenient and quick assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

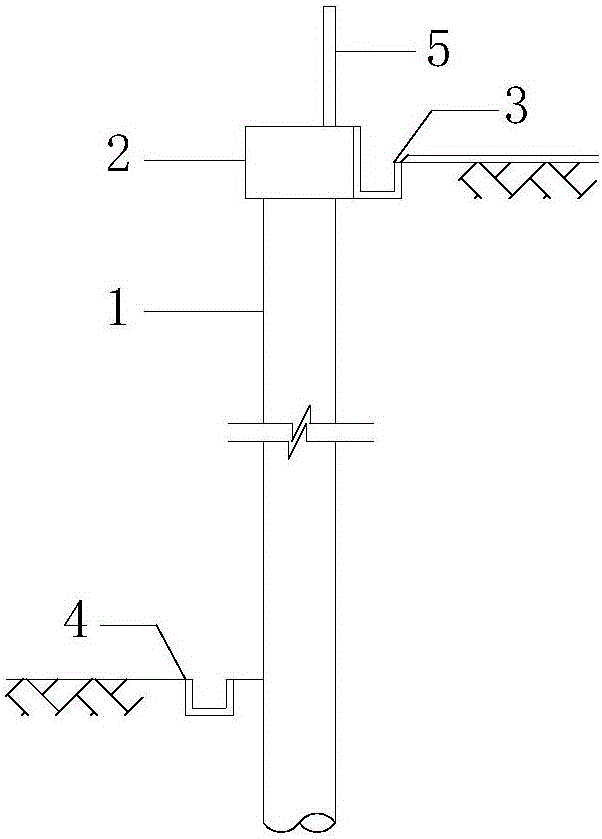

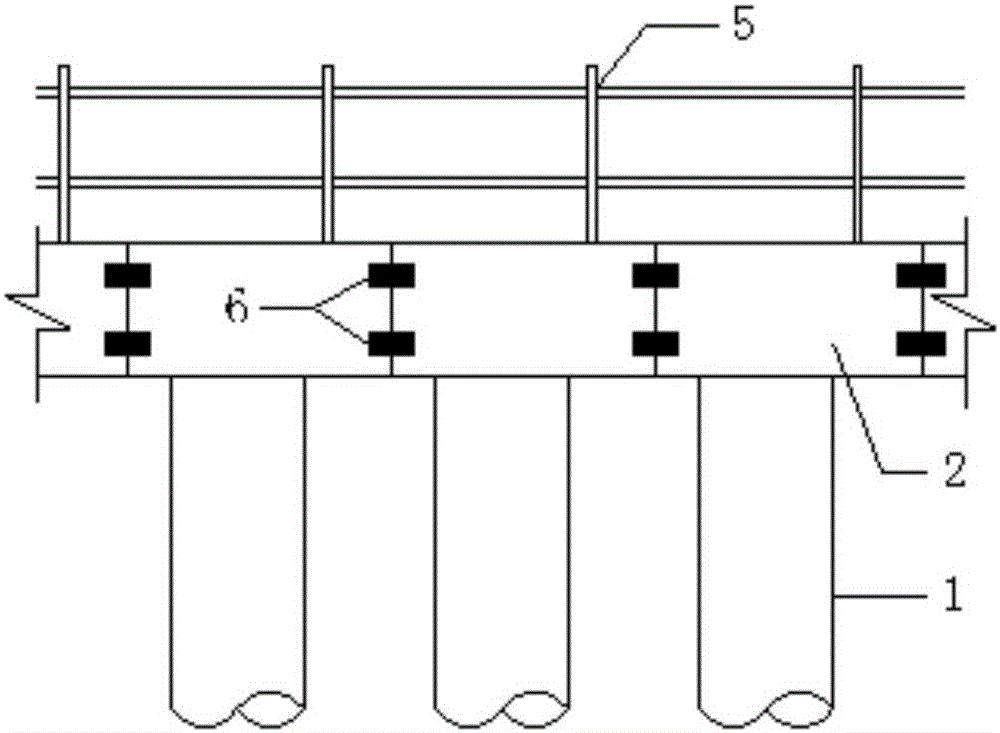

[0040] figure 1 and figure 2 As shown, an assembled foundation pit support structure system based on prefabricated components, including support piles, crown beams 2, guardrails 5 and drainage ditches, the support piles adopt prestressed pipe piles 1, image 3 As shown, the top of the support pile is provided with a multi-section assembled crown beam 2, the top of the crown beam 2 is provided with a guardrail 5, and the outside of the crown beam 2 is provided with a multi-section assembled foundation pit top drainage ditch 3, The foundation pit inside the crown beam 2 is provided with a multi-stage assembled foundation pit bottom drainage ditch 3, and the foundation pit top drainage ditch 3 and the foundation pit bottom drainage ditch 3 are prefabricated components.

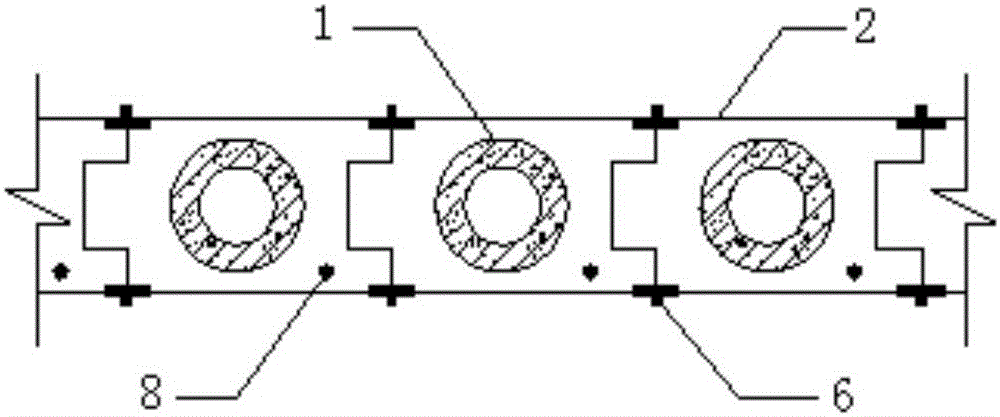

[0041] Figure 5-a and Figure 5-b As shown, the crown beam 2 is a prefabricated concre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com