Method for making raw ball arm blank with diversified inner wall thicknesses

A manufacturing method and club technology, which can be applied to household components, household appliances, other household appliances, etc., can solve the problems of heavy weight of hockey sticks, affect the performance of use, and be inflexible in use, and save the cost of silica gel and control the ball several degrees. Fast, feel good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The method for making rough cue blanks with inconsistent inner wall thicknesses described in this embodiment,

[0038] (1) Heat the bead mold for molding the silicone bead 2 used for ridge thickening to 62°C, then clean the inner surface, and apply a release agent;

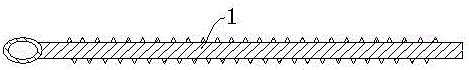

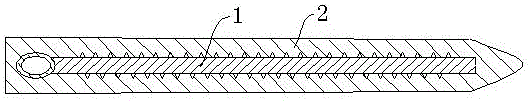

[0039] (2) Brush the silicone adhesive on the outer peripheral surface of the steel mandrel 1, and then bake the steel mandrel 1 until the surface is white; the structure of the steel mandrel 1 is as follows: figure 1 As shown; the outer peripheral surface of the steel mandrel 1 is provided with a spiral protrusion, and the cross-section of the protrusion is an isosceles triangle, and the two sides of the cross-section of the protrusion are the same, and the adjacent protrusions at the same axial position The distance between the protrusions is 0.1 cm, and the height of the protrusions is 0.1 cm. One end of the steel mandrel 1 is provided with a nut.

[0040] (3) Wrap the steel mandrel 1 with a strip-shap...

Embodiment 2

[0050] The method for making rough cue blanks with inconsistent inner wall thicknesses described in this embodiment,

[0051] (1) Heat the bead mold for molding the silicone bead 2 for ridge thickening to 85°C, then clean the inner surface and apply a release agent;

[0052] (2) Brush the silicone adhesive on the outer peripheral surface of the steel mandrel 1, and then bake the steel mandrel 1 until the surface is white; the structure of the steel mandrel 1 is as follows: figure 1 As shown; the outer peripheral surface of the steel mandrel 1 is provided with a spiral protrusion, and the cross-section of the protrusion is an isosceles triangle, and the two sides of the cross-section of the protrusion are the same, and the adjacent protrusions at the same axial position The distance between the bumps is 0.15cm, and the height of the bumps is 0.2cm. One end of the steel mandrel 1 is provided with a nut.

[0053] (3) Wrap the steel mandrel 1 with a strip-shaped silica gel sheet...

Embodiment 3

[0063] The method for making rough cue blanks with inconsistent inner wall thicknesses described in this embodiment,

[0064] (1) Heat the bead mold for molding the silicone bead 2 used for thickening the ridges to 70°C, then clean the inner surface and apply a release agent;

[0065] (2) Brush the silicone adhesive on the outer peripheral surface of the steel mandrel 1, and then bake the steel mandrel 1 until the surface is white; the structure of the steel mandrel 1 is as follows: figure 1 As shown; the outer peripheral surface of the steel mandrel 1 is provided with a spiral protrusion, and the cross-section of the protrusion is an isosceles triangle, and the two sides of the cross-section of the protrusion are the same, and the adjacent protrusions at the same axial position The distance between the protrusions is 0.12cm, and the height of the protrusions is 0.15cm. One end of the steel mandrel 1 is provided with a nut.

[0066] (3) Wrap the steel mandrel 1 with a strip-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com