Foaming furnace

A kind of foaming furnace, foaming sheet technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

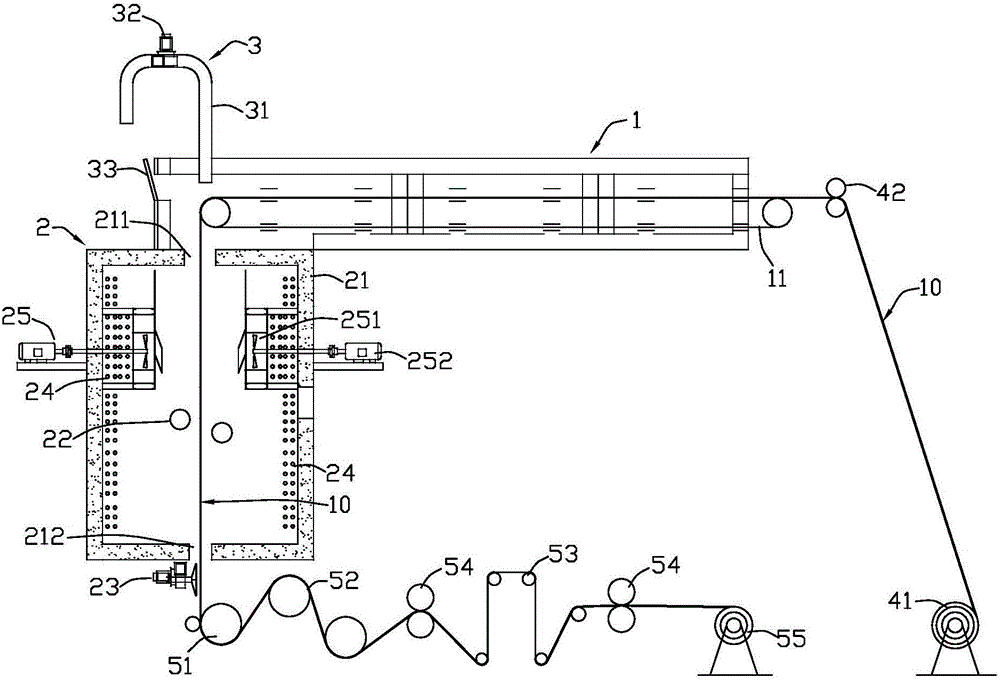

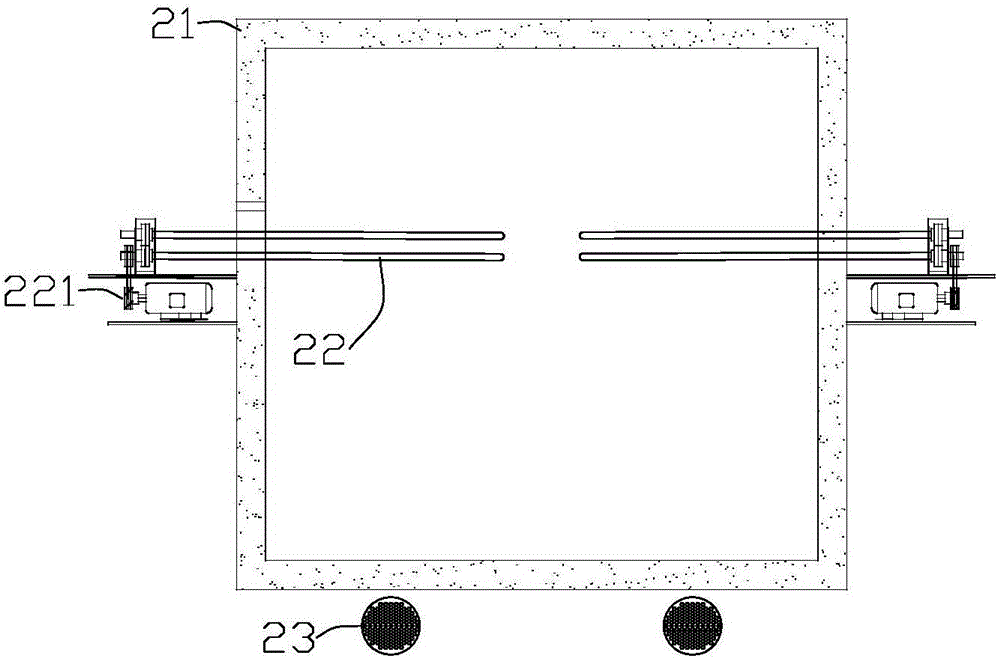

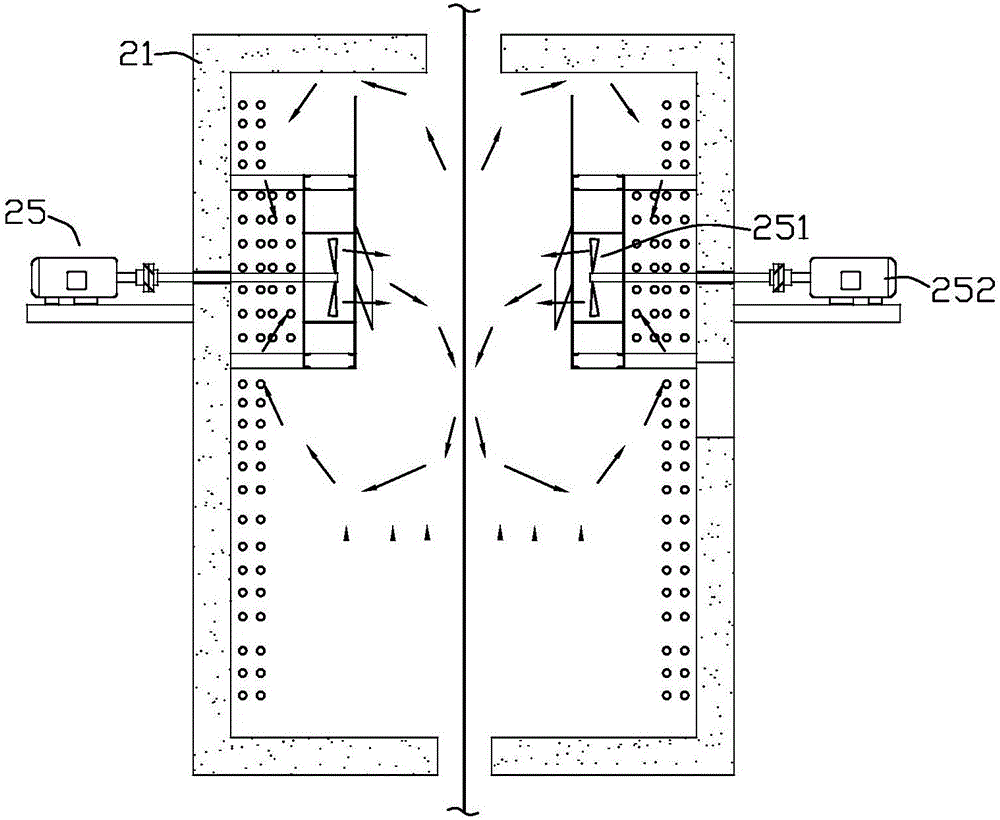

[0024] Such as figure 1 As shown, the foaming furnace of an embodiment of the present invention includes a horizontal furnace 1 and a vertical furnace 2 for the foamed sheet 10 to pass through in turn to be heated and foamed, and the vertical furnace 2 is arranged below the horizontal furnace 1; the foamed sheet 10 is uniformly preheated through the horizontal furnace 1 in the horizontal direction, and then enters the vertical furnace 2 in the vertical direction for foaming, so that the foamed sheet 10 is evenly heated, expanded and foamed. The foamed sheet 10 includes a cross-linked polyolefin sheet, and the foaming furnace is used for foaming the cross-linked polyolefin.

[0025] Wherein, the horizontal furnace 1 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com