Wireless-control safe abrasive wheel cutting machine

A grinding wheel cutting machine, wireless control technology, applied in the direction of manufacturing tools, grinding machine parts, grinding workpiece supports, etc., can solve the problems of personal injury and laborious operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

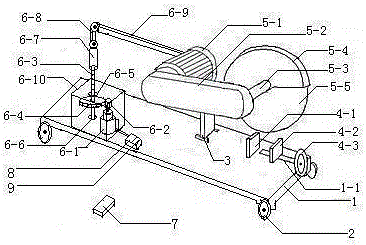

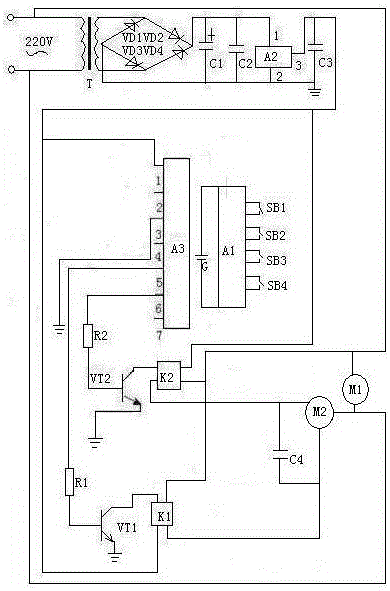

[0016] figure 1As shown in , the wireless control safety grinding wheel cutting machine is composed of a base plate 1, a wheel 2, a support seat 3, a clamping mechanism, a cutting mechanism, a control mechanism, a remote control unit 7, a voltage stabilizing unit 8 and a wireless receiving unit 9. There is an opening 1-1 in the upper right part of the rear end of the seat plate 1, and there are four wheels 2. The four wheels 2 are installed on the front, rear, left, and right side ends of the base plate 1 respectively, and the support seat 3 is installed on the upper middle rear end of the base plate 1. There is a bearing at the upper end of the support seat 3, and the middle part of the lower end of the cutting mechanism is installed on the bearing side end of the support seat 3. The lower end of the cutting mechanism can move up and down along the bearing of the support seat 3. The control mechanism is composed of a motor 6-1 and a driving gear 6-2. Drive shaft rod 6-3, driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com