Adjustable clamping mechanism, numerical control machining equipment and use method

A processing equipment and clamping technology, which is applied in the field of numerical control processing equipment, can solve the problems of clamping device deviation, inconsistent radius, high position requirements, etc., and achieve the effect of reducing the difficulty of adjustment, improving processing efficiency and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

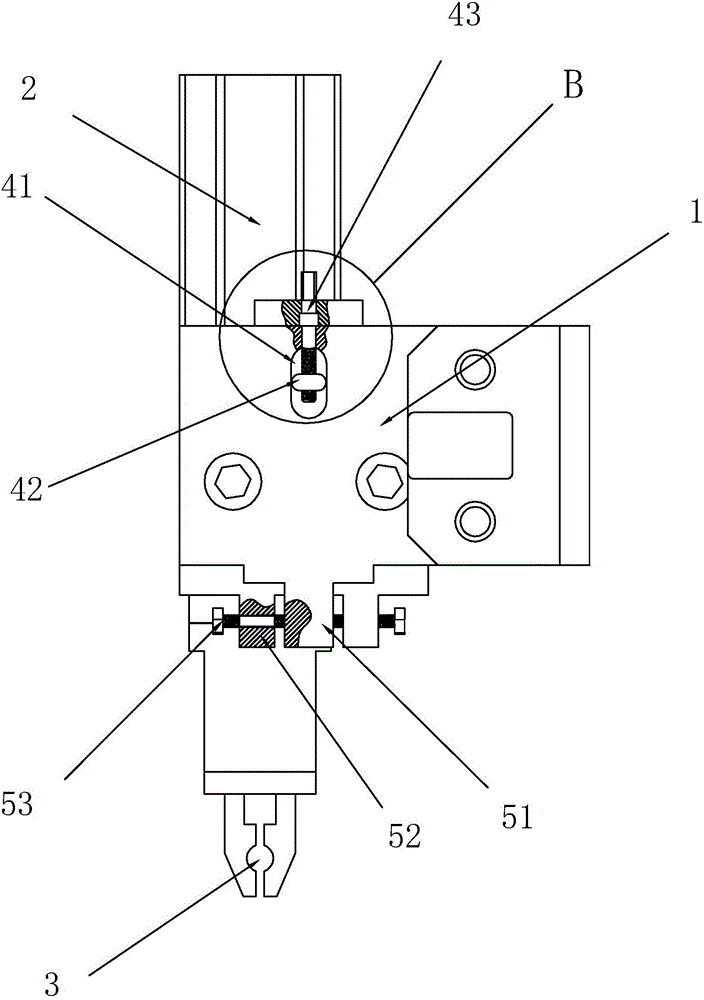

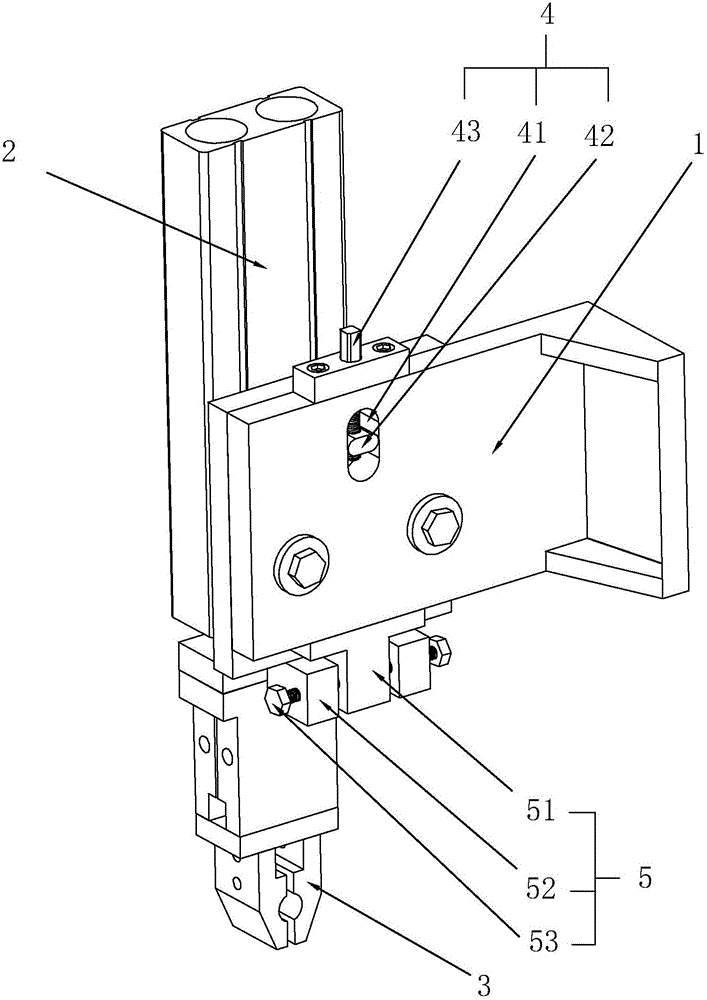

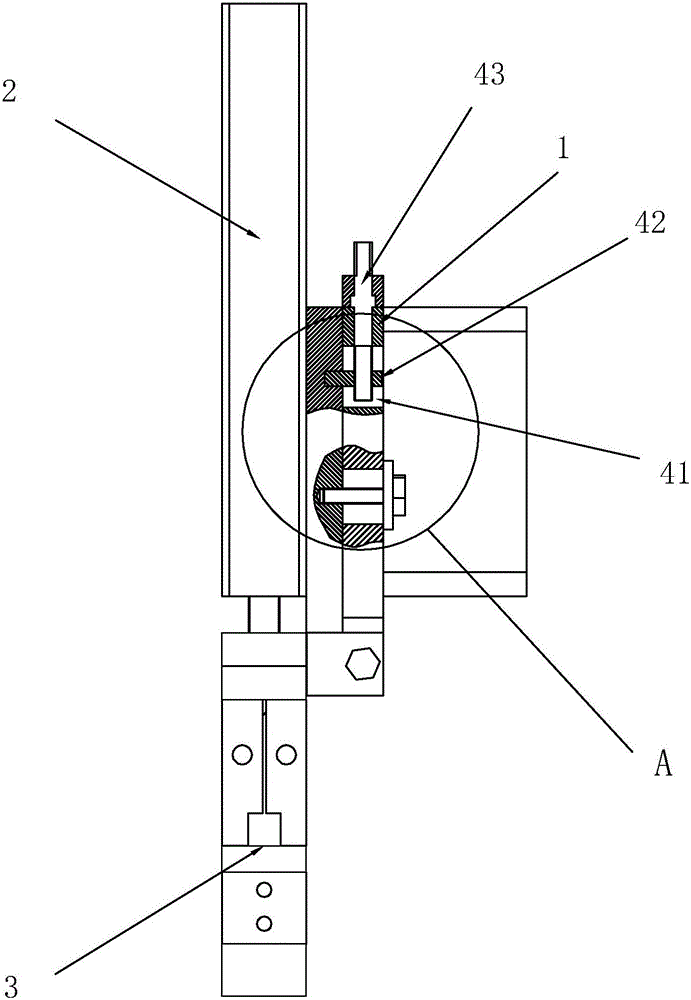

[0057] Embodiment one, see figure 1 As shown, an adjustable clamping mechanism includes a base 1, a clamping cylinder 2 is provided on the outer wall of the base 1, the clamping cylinder 2 is connected to an external air source, and the output end of the clamping cylinder 2 is provided with a The clamping part 3 for clamping the material, the clamping part 3 can be selected with pneumatic grippers and connected to an external air source, the base 1 is provided with a vertical adjustment part 4 for adjusting the up and down movement of the clamping cylinder 2, for adjusting The horizontal adjustment part 5 that the clamping cylinder 2 moves left and right, the vertical adjustment part 4 and the horizontal adjustment part 5 are distributed up and down.

[0058] see figure 1 , figure 2 , image 3 as well as Figure 5 As shown, the vertical adjustment part 4 includes an adjustment groove 41 located on the base 1, an adjustment pin 42 connected to the outer wall of the clampin...

Embodiment 2

[0062] Embodiment two, see Figure 6 as well as Figure 7 As shown, a kind of numerical control processing equipment comprises frame 19, and this frame 19 is provided with material transmission mechanism 6, the adjustable clamping mechanism in embodiment one, material processing mechanism 16, driving mechanism 17, adjustable clamping mechanism The mechanism is laterally slidably connected to the frame 19, and the drive mechanism 17 drives the adjustable clamping mechanism to reciprocate and slide between the material processing mechanism 16 and the material transmission mechanism 6, wherein the drive mechanism 17 adopts a cylinder, and the drive mechanism 17 The telescopic direction is consistent with the sliding direction of the adjustable clamping mechanism, and the material transmission mechanism 6 and the material processing mechanism 16 are respectively located at two extreme sliding end positions of the adjustable clamping mechanism.

[0063] see Figure 8 as well as ...

Embodiment 3

[0068] Embodiment three, a method for using the numerical control processing equipment as in embodiment two, comprising the following steps:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com