A kind of coated sand submersible pump impeller blade sand mold and its manufacturing method

An impeller blade, submersible pump technology, applied in the direction of casting, core, molding machine, etc., can solve the problems of large capital investment, low production efficiency, cumbersome process, etc., to achieve the effect of no environmental pollution, ingenious design, high finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

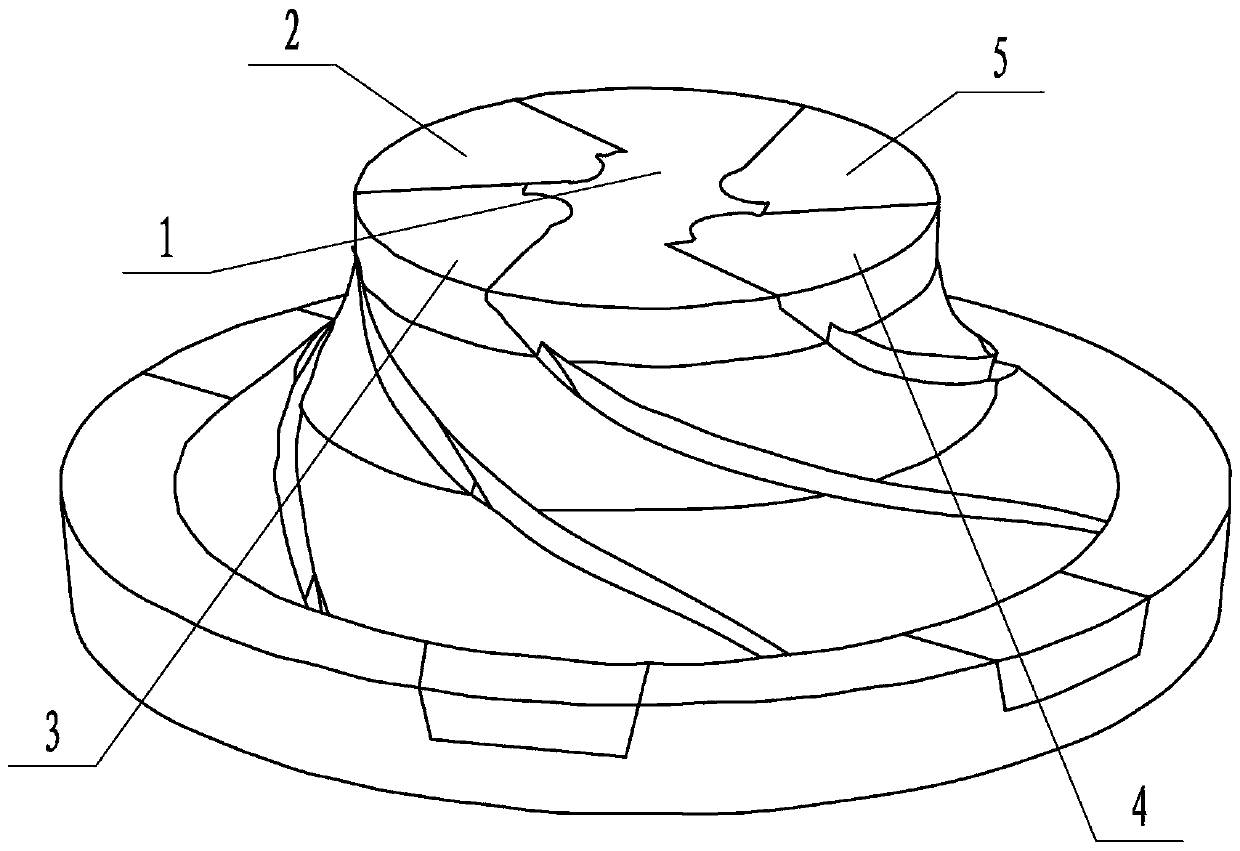

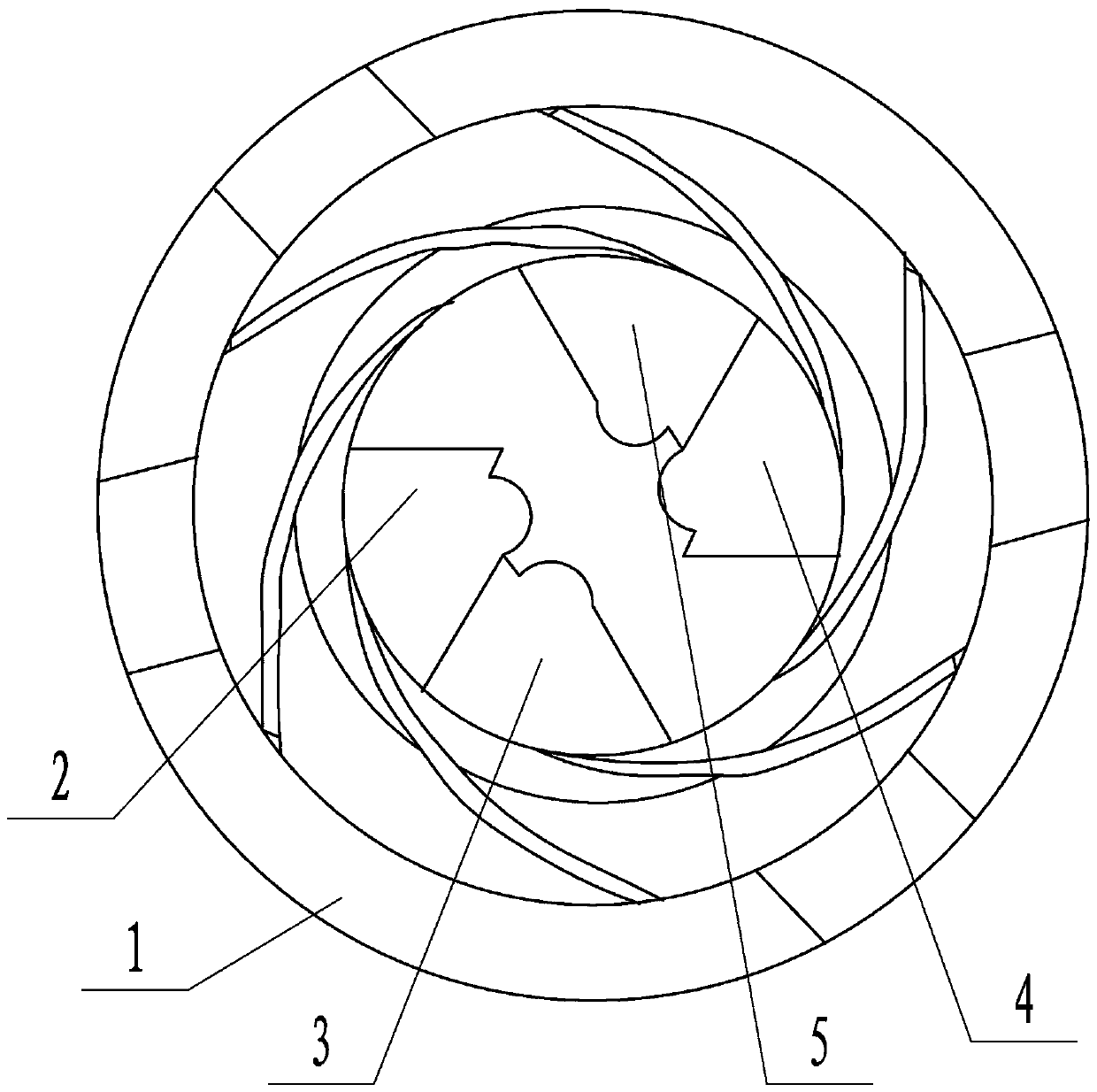

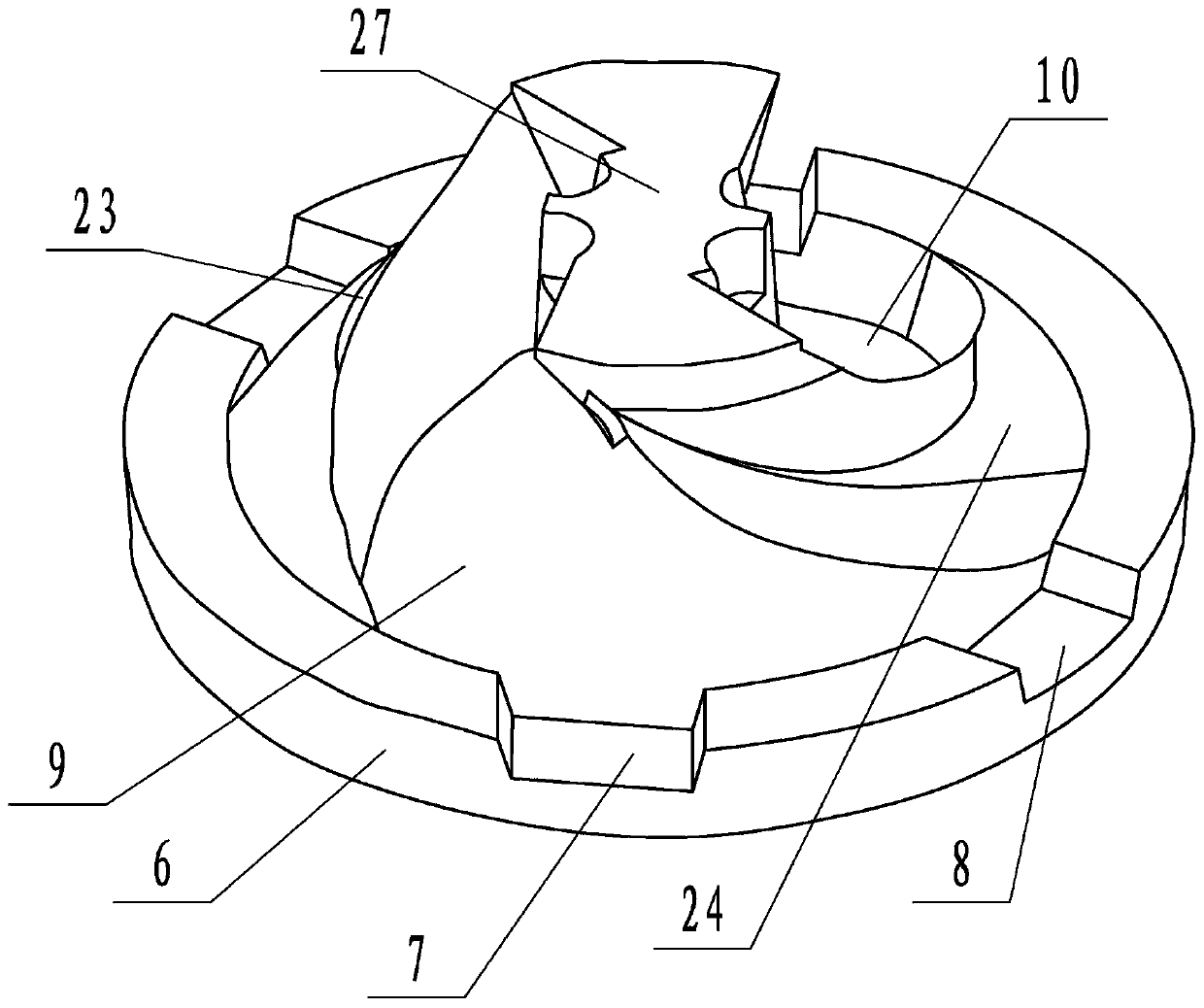

[0051] Such as Figure 1-8 As shown, the present invention includes a skeleton sand mold 1 corresponding to the submersible pump impeller cavity and a blade sand mold corresponding to the channel between the impeller blades. The blade sand mold is embedded on the skeleton sand mold 1, and between the blade sand molds and / or blades A gap corresponding to the impeller blade is provided between the sand mold and the skeleton sand mold 1 .

[0052] Further, the skeleton sand mold 1 includes the first connecting rib 23 of the spiral structure, the second connecting rib 24 of the spiral structure, the lower round table 6 connected with the lower ends of the first connecting rib 23 and the second connecting rib 24 respectively, and the first connecting rib 23 and the first connecting rib respectively. The upper cross frame 27 connected to the upper end of the connecting rib 23 and the second connecting rib 24; the first connecting rib 23 has the same structure as the second connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com