Water-based paint drying system

A drying system and water-based paint technology, applied in the field of drying systems, can solve the problems of limited angle and coverage of hot air blowing, unfavorable rapid operation of enterprises, and different drying degrees, etc., to shorten drying time and achieve excellent economy. Benefit and social benefit, the effect of less floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

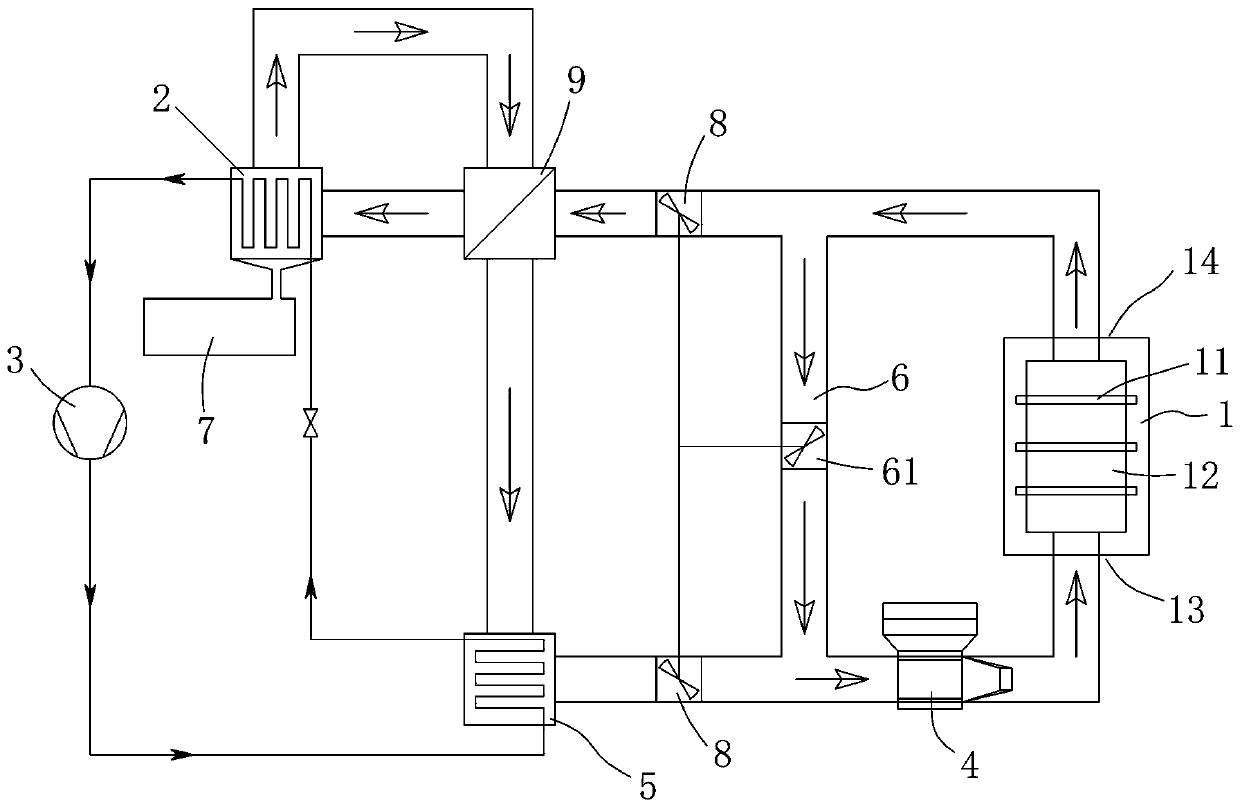

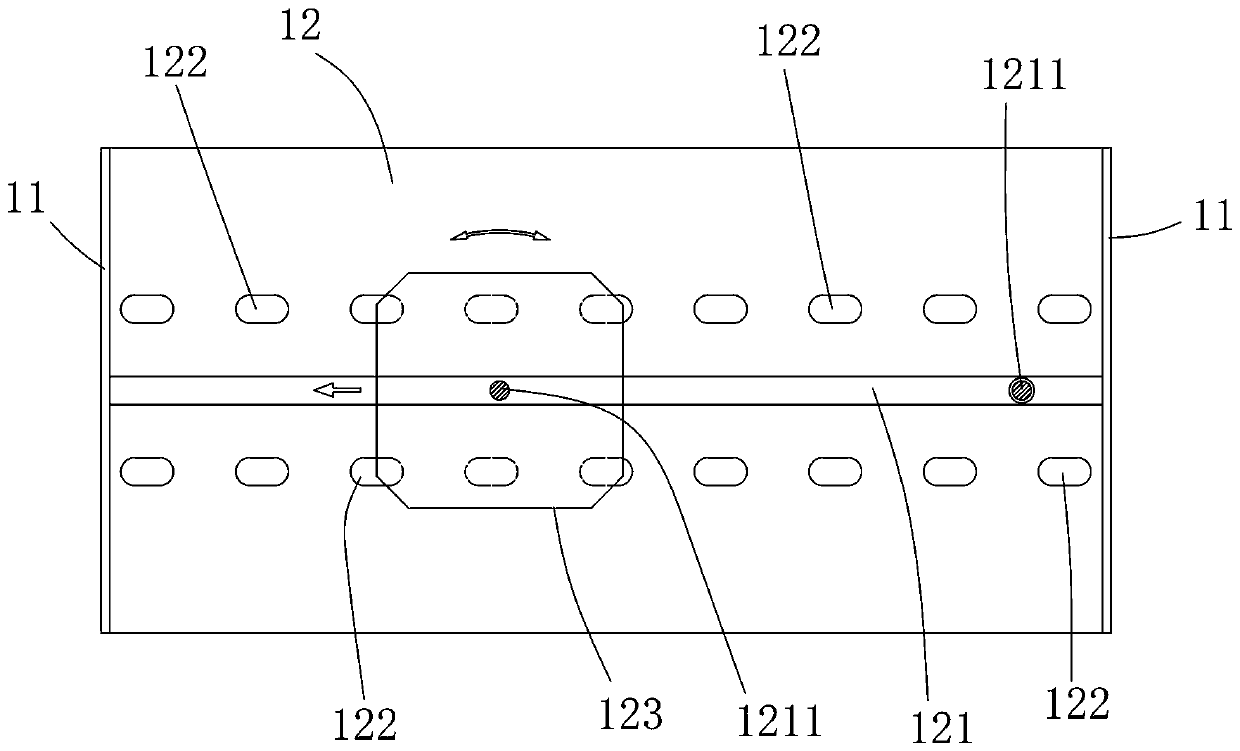

[0025] refer to figure 1 , 2 As shown, the present invention relates to a water-based paint drying system. The system has a closed air duct and at least includes a drying room 1 that can provide a closed drying space, a heat pump unit and a burner 4. The drying room 1 has an air inlet end 13 and an air return end 14; the heat pump unit includes an evaporator 2, a compressor 3 and a condenser 5, the compressor 3 drives the refrigerant to circulate through the condenser 5 and the evaporator 2, and the evaporator 2 is connected to the drying The air return end 14 of the room 1 is provided with return air for cooling and dehumidification, and the condenser 5 is connected to the air outlet end of the evaporator 2 for heating up with dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com