Nanographene low-voltage power cable and manufacturing method thereof

A technology of nano-graphene and low-voltage power, which is applied in the manufacture of power cables, cables/conductors, and used to reduce the size of conductors/cables. Reduced production costs, ease of installation, and improved conduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

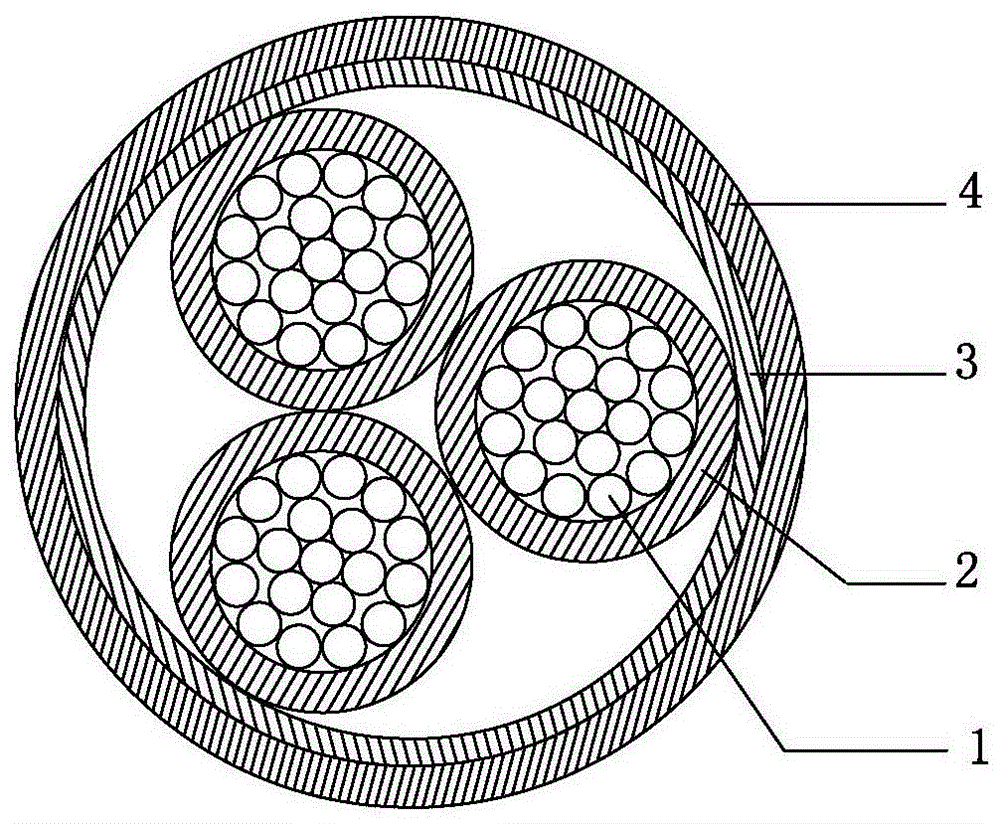

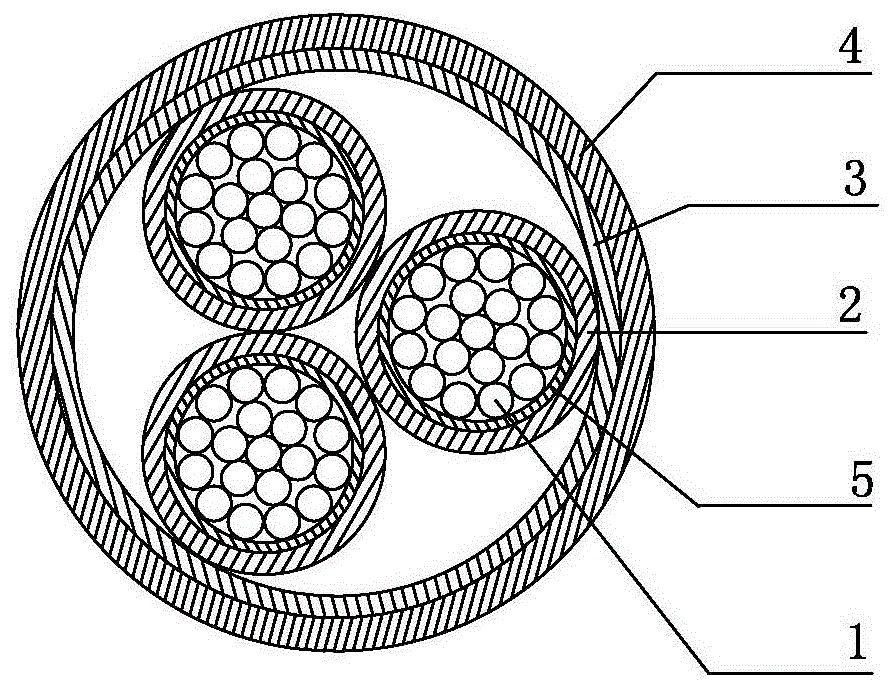

[0020] refer to figure 2 Make the invention. The nano-graphene low-voltage power cable includes a conductor 1, an insulating layer 2, a tape layer 3 and an outer sheath layer 4. The conductor 1 is formed by twisting a plurality of copper wires or aluminum wires along the length direction, and is characterized in that: The conductor 1 is covered with a nano-graphene layer 5, and the nano-graphene layer 5 is covered with an insulating layer 2 to form an insulated wire core; a tape layer 3 is provided on the outside of 2-6 insulated wire cores , forming a cable core; the cable core is covered with an outer sheath layer 4 .

[0021] The outer edge of the section perpendicular to the length direction of the conductor 1 is circular, fan-shaped or tile-shaped.

[0022] The nano-graphene layer 5 is made by electrostatic powder spraying, with a thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com