Method for measuring content of vanadium in rare earth alloy

A technology of rare earth alloys and determination methods, which is applied in the field of metallurgical analysis, can solve the problems that rare earth alloys cannot be directly applied, and there is no national standard method for analysis and detection, so as to meet the needs of scientific research and production, and the analysis method is simple, fast, and precise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention is described below in conjunction with accompanying drawing:

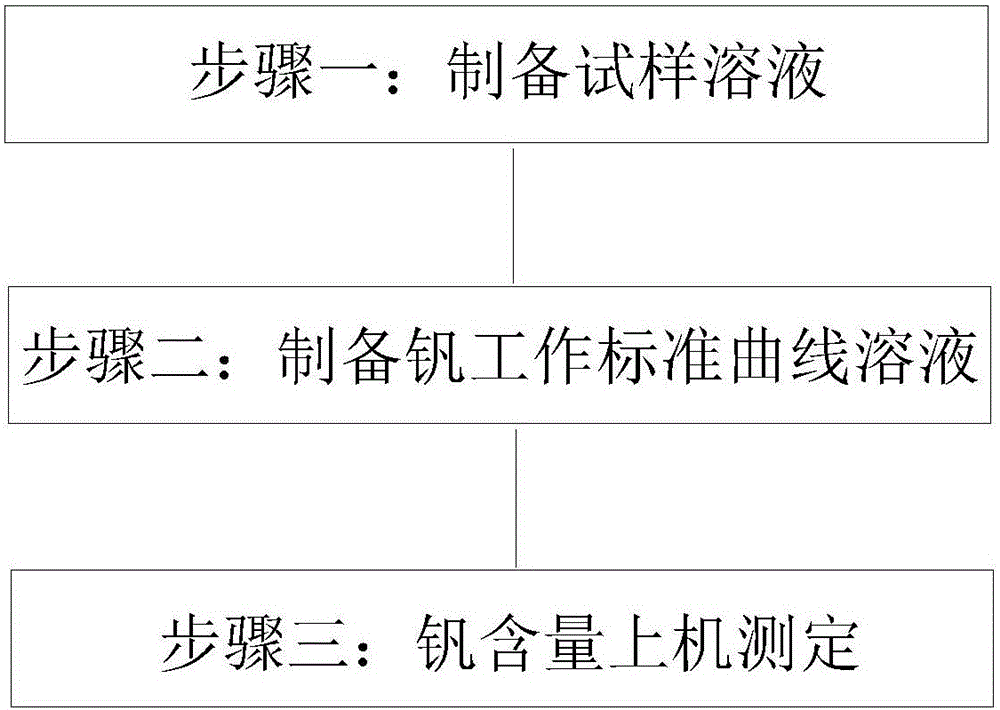

[0020] The method steps of this specific embodiment are as figure 1 As shown, in the following specific embodiments, the reagents used are specifically:

[0021] Nitric acid: ρ1.42, superior grade; hydrochloric acid: ρ1.19, superior grade; hydrofluoric acid: ρ1.13, superior grade; perchloric acid: ρ1.68, superior grade; hydrochloric acid (1+1) , prepared in proportion with high-grade pure hydrochloric acid and high-purity water, and the experimental water is secondary pure water.

[0022] The specific operation steps are as follows: Weigh 0.1-0.2g rare earth alloy sample, accurate to 0.1mg, put it into a polytetrafluoroethylene beaker, add 10-15mL nitric acid, 5mL hydrofluoric acid, heat and dissolve on an electric heating plate at a low temperature of 100°C , add 5mL perchloric acid to fume until almost dry, remove and cool, add 10mL (1+1) hydrochloric acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com