A hot blast stove device and heating method applied to polyacrylamide drying

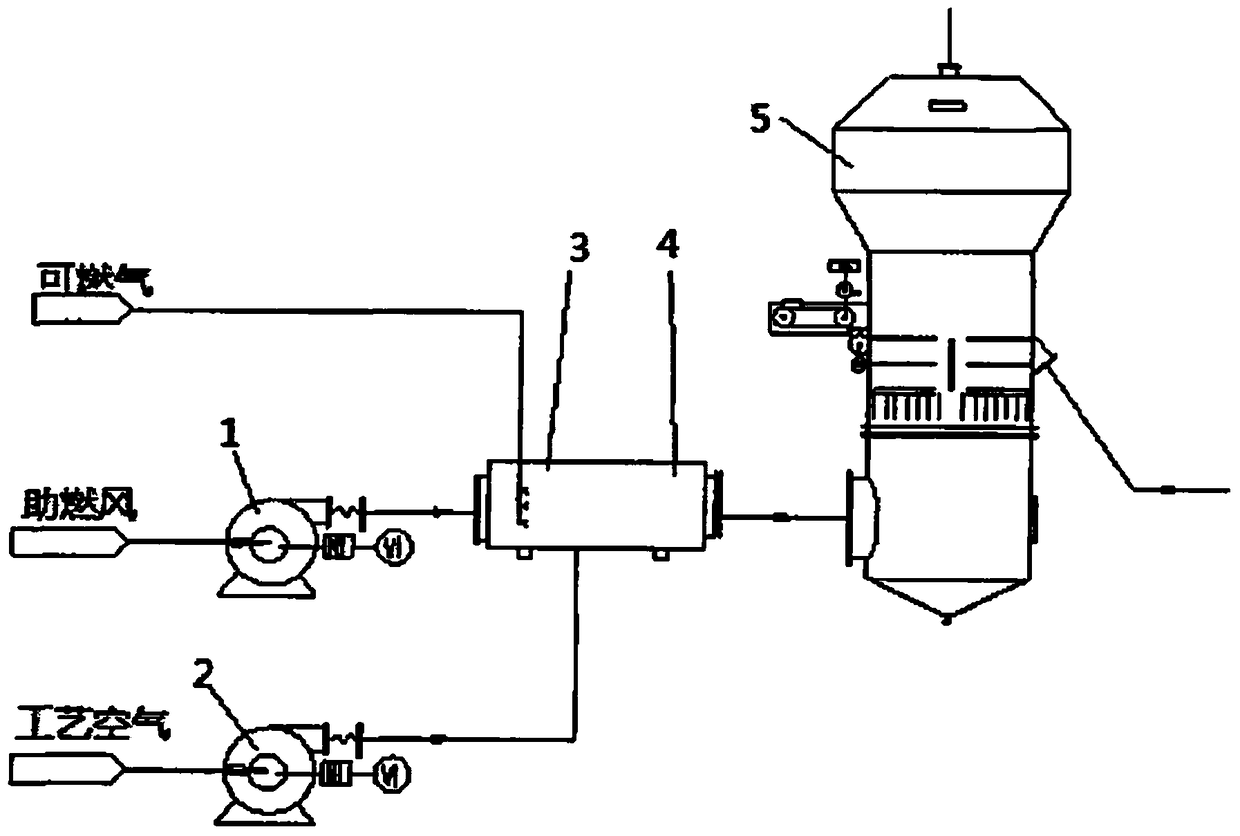

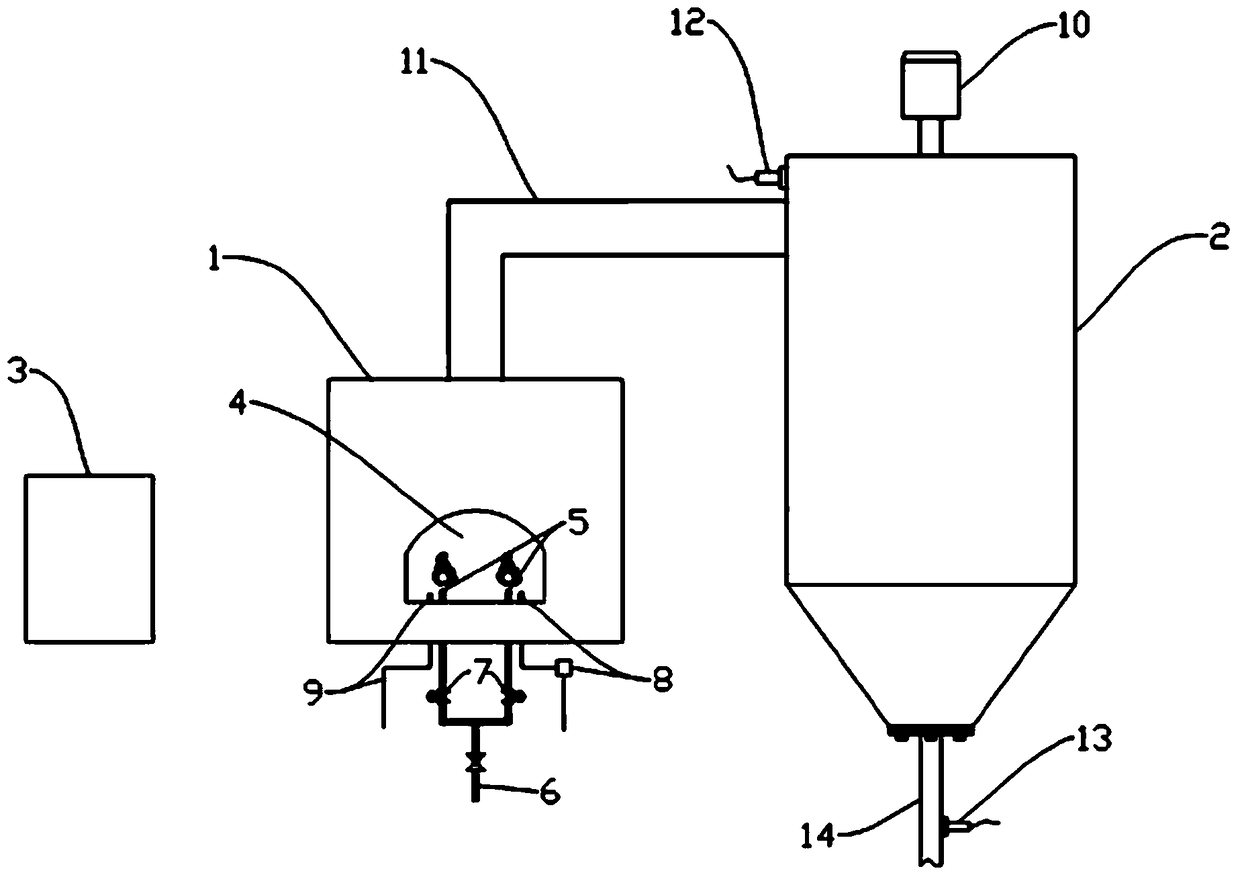

A technology of polyacrylamide and hot blast stove, which is applied in the direction of drying gas arrangement, drying, dryer, etc., can solve the problem that no blower can not produce positive pressure combustion, is not suitable for polyacrylamide drying, and the hot gas pressure cannot reach the pressure value. and other problems, to achieve the effect of preventing the dead bed phenomenon, small resistance parts in the furnace, and small pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

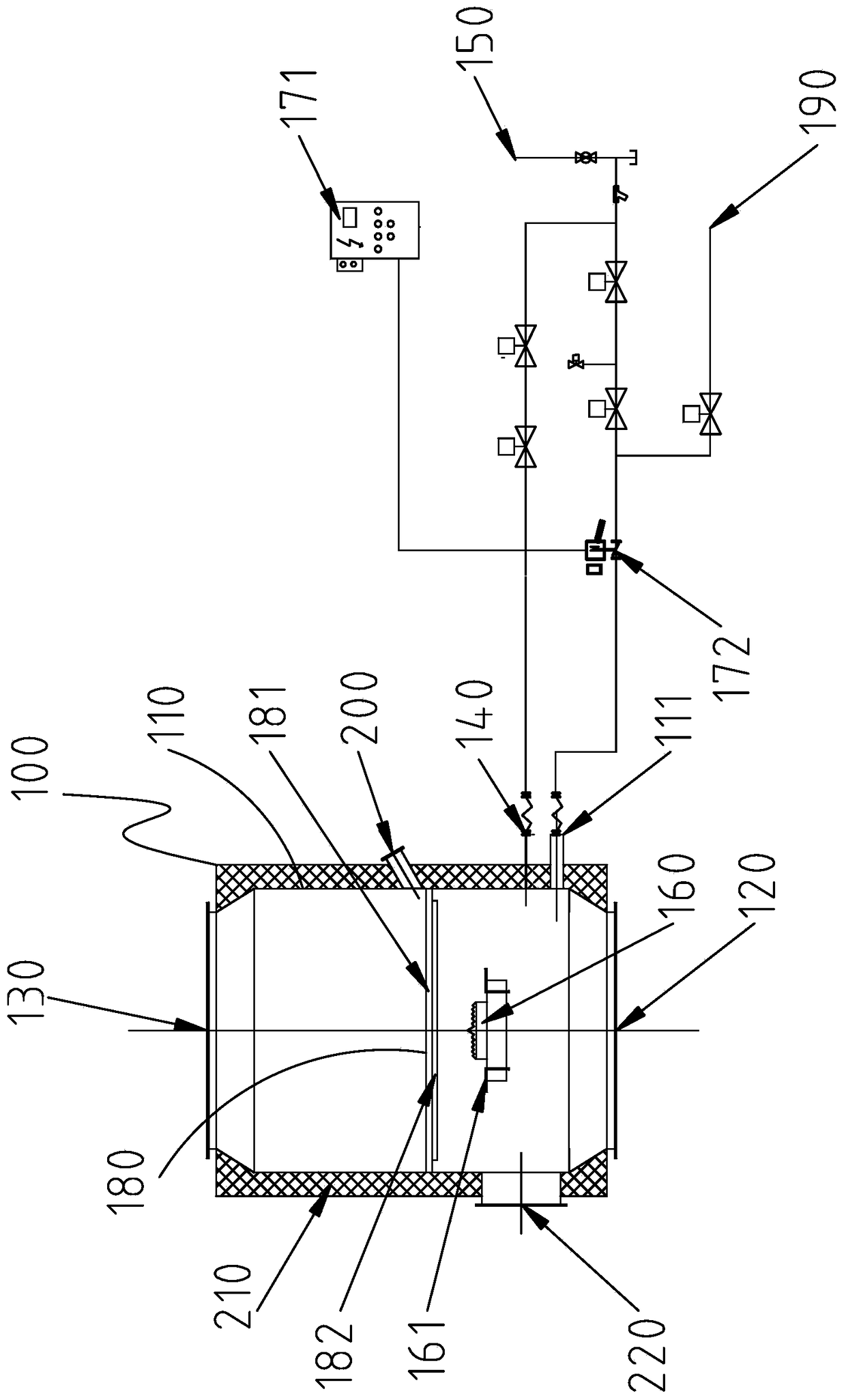

[0062] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

[0063] refer to image 3 and Figure 4 , The hot blast stove device 100 applied to polyacrylamide (PAM) drying of the present invention includes a furnace body 110, a cold air inlet 120, a hot air outlet 130, an ignition pipeline 140, an air intake pipeline 150, a burner 160 and a control system.

[0064] The burner 160 is arranged in the furnace body 110 , and the burner 160 is supported by a burner fixing bracket 161 , and the burner fixing bracket 161 is arranged near the cold air inlet 120 . The cold air inlet 120 , the hot air outlet 130 , the ignition pipeline 140 and the air intake pipeline 150 are respectively arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com