Safe, energy-saved and multifunctional bathroom cabinet

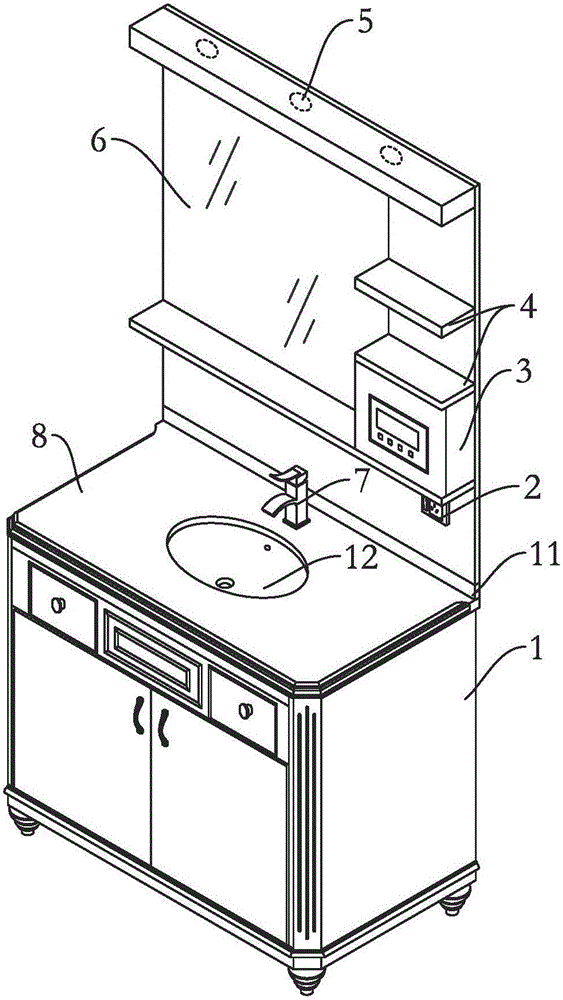

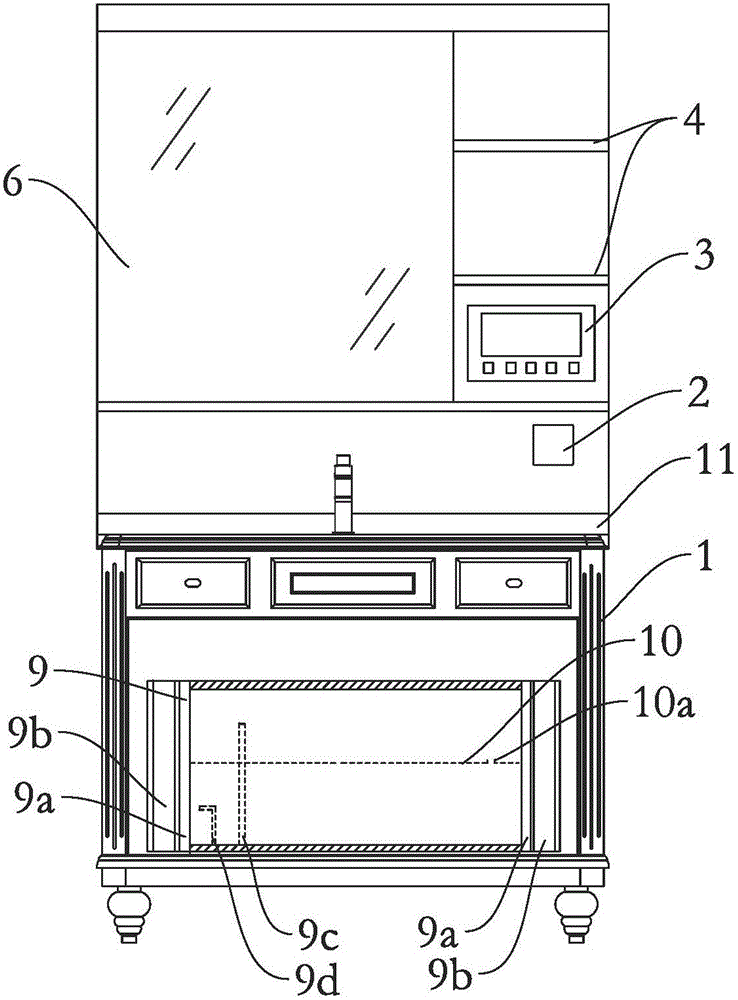

A bathroom cabinet and multi-functional technology, applied in the field of bathroom cabinets, can solve the problems of easy water ingress, damage, poor operation convenience, etc., and achieve the effects of high-quality anti-corrosion, uniform water temperature, and convenient setting and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Get 40 parts by weight of vinyl resin, 1 part of polycarboxylate sodium salt dispersant HF-50500, 9 parts of sepiolite fiber, 80 parts of nanometer calcium carbonate, 10 parts of silicon micropowder, mix and stir in mixer, make Nano-calcium carbonate and silicon micropowder are fully dispersed in the resin;

[0032] (2) Get 5 parts of furan resin by weight, join in the material in step (1) and mix uniformly;

[0033] (3) Take 1 part of diaminodiphenylmethane in parts by weight, and 0.1 part of aluminum tripolyphosphate is added to the material after step (2), and mixed and stirred evenly in a mixer to form agglomerated composite materials;

[0034] (4) Pour the lumpy composite material into a mold, and press at a temperature of 140 to 160 degrees Celsius and a pressure of 15 to 25 MPa for 35 minutes to obtain a formed table top.

Embodiment 2

[0036] (1) Get 60 parts by weight of vinyl resin, 2 parts of polycarboxylate sodium salt dispersant HF-50500, 15 parts of sepiolite fiber, 100 parts of nanometer calcium carbonate, 20 parts of silicon micropowder, mix and stir in mixer, make Nano-calcium carbonate and silicon micropowder are fully dispersed in the resin;

[0037] (2) Get 8 parts of furan resins by weight, join in the material in step (1) and mix uniformly;

[0038] (3) Take 1.5 parts of diaminodiphenylmethane in parts by weight, and 0.2 parts of aluminum tripolyphosphate are added to the material after step (2), and mixed and stirred in a mixer to form a lumpy composite material;

[0039] (4) Pour the dough-like composite material into a mold, and press at a temperature of 140 to 160 degrees Celsius and a pressure of 15 to 25 MPa for 45 minutes to obtain a formed table top.

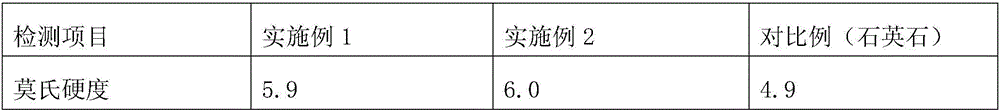

[0040] The countertop material made by the above method and formula can be evenly dispersed in vinyl resin due to the selection of disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com