Explosion-proof electric control cabinet integrally skid-mounted sulfur resistant compressor

A technology for compressors and electric control cabinets, applied in liquid variable capacity machinery, pump control, mechanical equipment, etc., can solve the problems of high cable procurement cost and large wiring workload, so as to improve corrosion resistance and reduce procurement costs. , turn on the convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

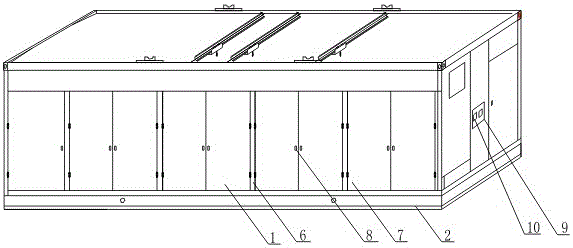

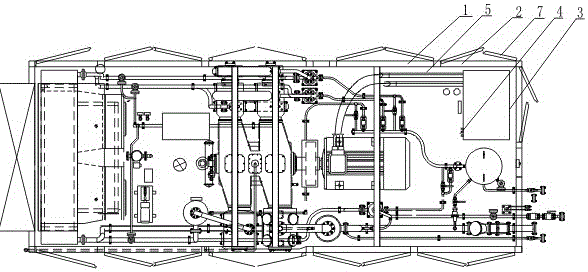

[0037] like figure 1 , figure 2 As shown, the explosion-proof electric control cabinet is integrated into a skid-type anti-sulfur compressor, including the compressor. The compressor is covered with a soundproof room 1, and the lower end of the soundproof room 1 is detachably fixed on the compressor base 2. The soundproof room 1 An explosion-proof electric control cabinet 3 is arranged inside, and the explosion-proof electric control cabinet 3 is fixed on the base 2 of the compressor.

Embodiment 2

[0039] In this embodiment, on the basis of Embodiment 1, the compressor is provided with a sensor, and a processor is provided in the explosion-proof electric control cabinet 3, and the sensor and the input end of the processor realize signal connection; the output end of the processor is electrically connected with a warning light 4.

Embodiment 3

[0041] In this embodiment, on the basis of embodiment 1 or embodiment 2, the compressor is provided with a sensor, and the explosion-proof electric control cabinet 3 is provided with a processor, and the sensor and the input end of the processor realize signal connection; the output end of the processor Connected to the motor on the compressor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com