Seawater tower for self-elevating drilling platform and self-elevating drilling platform

A drilling platform, self-elevating technology, applied in hydraulic engineering, underwater structures, artificial islands, etc., can solve problems such as the loss of seawater supply on the platform, affecting the drilling operation of the platform, and the huge force on the seawater tower, so as to eliminate major hidden dangers. , The effect of convenient maintenance and saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, technical solution and advantages of the present invention more clear, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

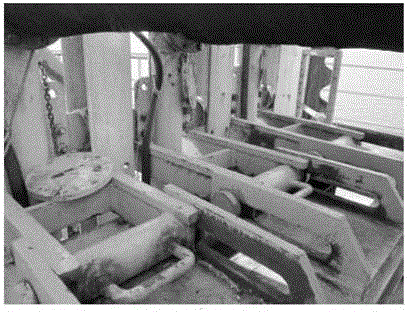

[0033] like figure 1 As shown, the embodiment of the present invention provides a seawater tower for a jack-up drilling platform, the jack-up drilling platform includes a pile leg 1 and a spud shoe 2, and the seawater tower includes a slide rail 3, a lifting pipe 4, Submersible pump 5, and seawater supply auxiliary device 6,

[0034] The slide rail 3 is fixedly installed on the chord of the leg 1, the bottom of the slide rail 3 has a blocking device, and the slide rail 3 has a pin hole at a certain interval,

[0035] The seawater supply auxiliary device 6 is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com