Phosphoric Acidification Corrosion Inhibitor

A technology of acidifying corrosion inhibitor and phosphoric acid, which is applied in the field of phosphoric acid acidifying corrosion inhibitor, and achieves the effect of small addition, low cost and good synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

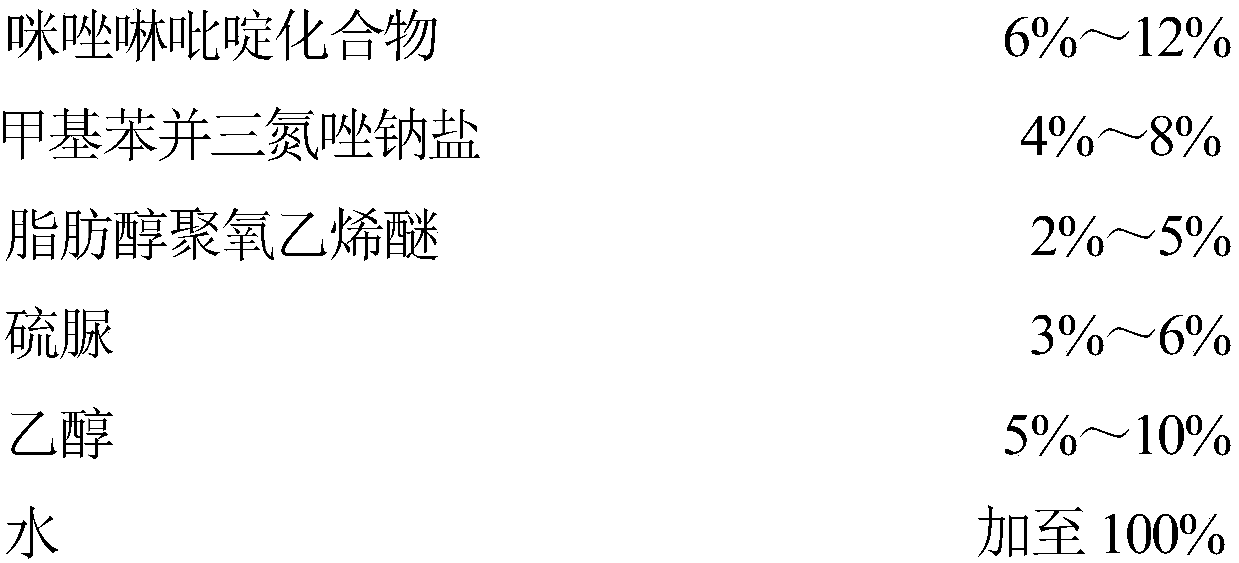

[0018] Take the preparation of phosphoric acid acidification corrosion inhibitor 1kg of the present invention as an example, it is made of the raw materials of following mass proportion:

[0019]

[0020] Its preparation method is: 80g 2-(1-(aminoethyl)imidazolin-2-yl)pyridine, 50g methyl benzotriazole sodium salt, 30g fatty alcohol polyoxyethylene ether, 40g thiourea, 70g Add ethanol to 730g of water and stir evenly.

Embodiment 2

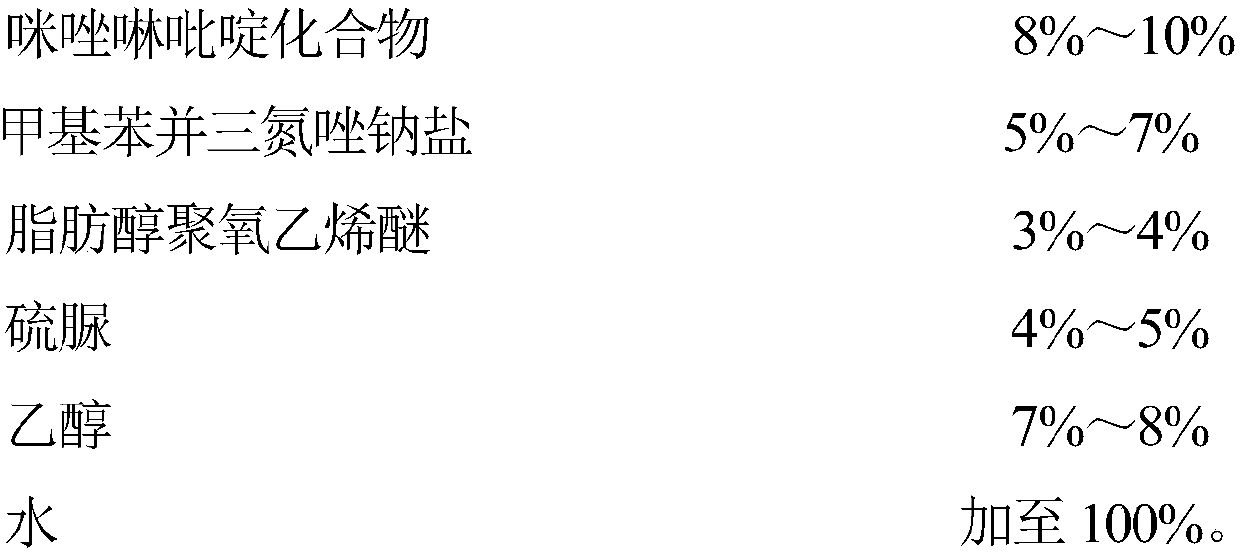

[0022] Take the preparation of phosphoric acid acidification corrosion inhibitor 1kg of the present invention as an example, it is made of the raw materials of following mass proportion:

[0023]

[0024]

[0025] Its preparation method is identical with embodiment 1.

Embodiment 3

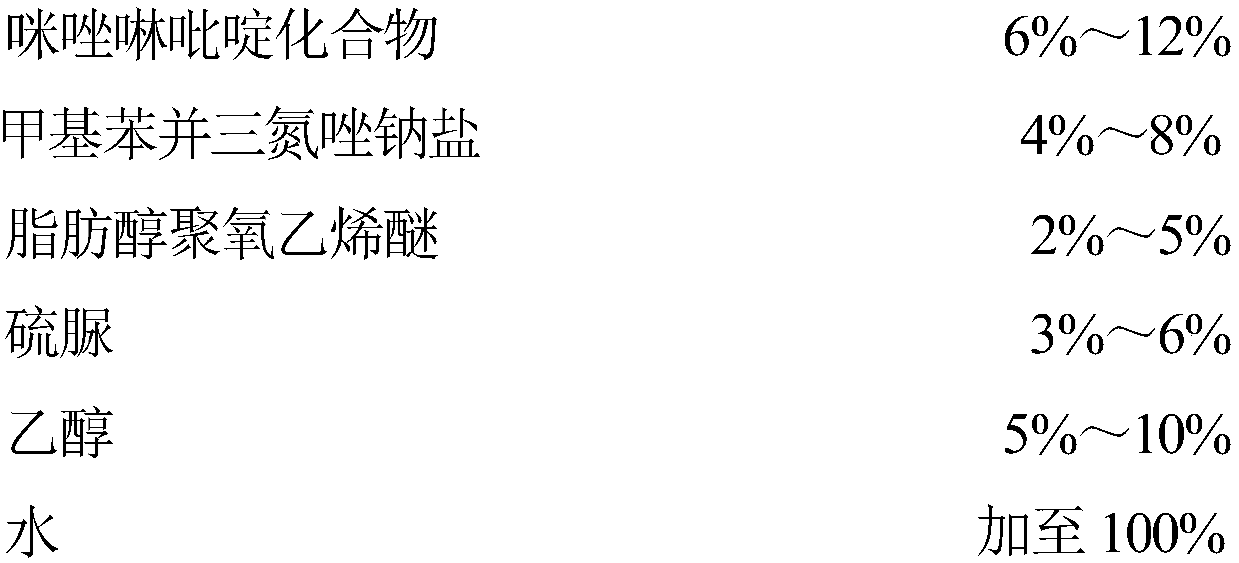

[0027] Take the preparation of phosphoric acid acidification corrosion inhibitor 1kg of the present invention as an example, it is made of the raw materials of following mass proportion:

[0028]

[0029] Its preparation method is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com