Lead plaster desulfurization method based on gas-liquid mixed flow

A lead paste, gas-liquid technology, applied in the field of lead paste desulfurization of waste lead-acid batteries, can solve problems such as environmental damage, and achieve the effects of strengthening effective contact, obvious advantages, and shortening desulfurization time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

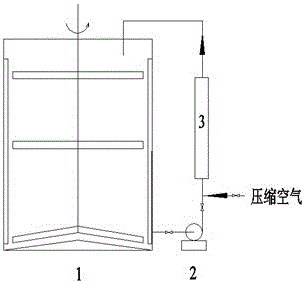

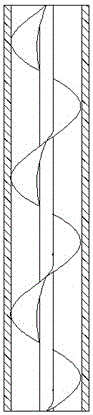

[0018] A kind of lead paste desulfurization method based on gas-liquid mixed flow provided by the invention, such as figure 1 As shown, the lead paste slurry with a mass fraction of 20% is prepared in the lead paste storage tank 1, and the volume is 5m 3 , with Na 2 CO 3 As a desulfurizer, Na 2 CO 3 with PbSO 4 The dosing ratio is 1:1.05, the lead paste slurry and the desulfurizer are stirred evenly, and then the circulation pump 2 is turned on. The lead paste slurry is boosted by the circulation pump 2 and mixed with compressed air, and then enters the desulfurizer 3, and a spiral piece is installed inside the desulfurizer 3 , the gas-liquid mixed flow forced desulfurization is carried out in the desulfurizer 3, and the lead paste slurry circulates among the storage tank 1, the circulation pump 2 and the desulfurizer 3, and the flow rate of the circulation pump 2 is 30m 3 / h, the liquid-gas ratio is controlled at 1:1.2, and the flow rate of the lead paste slurry in the d...

Embodiment 2

[0021] A kind of lead paste desulfurization method based on gas-liquid mixed flow provided by the invention, such as figure 1 As shown, a lead paste slurry with a mass fraction of 40% is prepared in the lead paste storage tank 1, and the volume is 5m 3 , with Na 2 CO 3 As a desulfurizer, Na 2 CO 3 with PbSO 4 The dosing ratio is 1:1.1, the lead paste slurry and the desulfurizer are stirred evenly, and then the circulation pump 2 is turned on. The lead paste slurry is boosted by the circulation pump 2 and mixed with compressed air, and then enters the desulfurizer 3, and the desulfurizer 3 is equipped with a swirl flow In the desulfurizer 3, the gas-liquid mixed flow forced desulfurization is carried out. The lead paste slurry is circulated among the storage tank 1, the circulation pump 2 and the desulfurizer 3. The flow rate of the circulation pump 2 is 50m3 / h, and the liquid-gas ratio is controlled at 1: 1.3, the flow rate of the lead paste slurry in the desulfurizer 3 i...

Embodiment 3

[0024] A kind of lead paste desulfurization method based on gas-liquid mixed flow provided by the invention, such as figure 1 As shown, the lead paste slurry with a mass fraction of 60% is prepared in the lead paste storage tank 1, and the volume is 5m 3 , use (NH 4 ) 2 CO 3 As a desulfurizer, (NH 4 ) 2 CO 3 with PbSO 4 The dosing ratio is 1:1.2, the lead paste slurry and the desulfurizer are stirred evenly, and then the circulation pump 2 is turned on. After the lead paste slurry is boosted by the circulation pump 2, it is mixed with compressed air, and then enters the desulfurizer 3, and a spiral piece is installed inside the desulfurizer 3 , the gas-liquid mixed flow forced desulfurization is carried out in the desulfurizer 3, the lead paste slurry circulates among the storage tank 1, the circulation pump 2 and the desulfurizer 3, and the flow rate of the circulation pump 2 is 50m 3 / h, the liquid-gas ratio is controlled to be 1:1.3, and the flow rate of the lead pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com