A method of collecting chlorella cultured in pig farm waste water

A technology for pig farm wastewater and chlorella, which is applied in the field of microbial culture and collection, can solve the problems of restricting the industrialization process of microalgae oil production, unfavorable mass application, low culture density, etc., and achieves good economic benefits and reduces collection costs. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The cultivation of embodiment 1 chlorella 34-2 in pig farm waste water

[0025] 1. Chlorella sp. 34-2 is observed under a microscope. The algal strain is spherical or oval, with a diameter of 4-8um. Each cell has a goblet-shaped pigment body and a nucleus. The cell wall is thinner. The chlorella strain (Chlorellasp.) 34-2 was preserved on May 15, 2014 in the General Microbiology Center of the China Committee for the Collection of Microorganisms (CGMCC for short), address: No. 3, Yard No. 1, Beichen West Road, Chaoyang District, Beijing , Institute of Microbiology, Chinese Academy of Sciences, Zip Code 100101), the preservation number is CGMCCNo.9225, and the classification is named as Chlorella sp.

[0026] 2. Pig raising wastewater is taken from Hongyun Farm in Changping District. Before dilution, the wastewater is precipitated and filtered with gauze. See Table 1 for the total nitrogen, ammonia nitrogen, total phosphorus, COD and pH values in pig wastewater.

[0...

Embodiment 2

[0031] The collection of embodiment 2 Chlorella 34-2

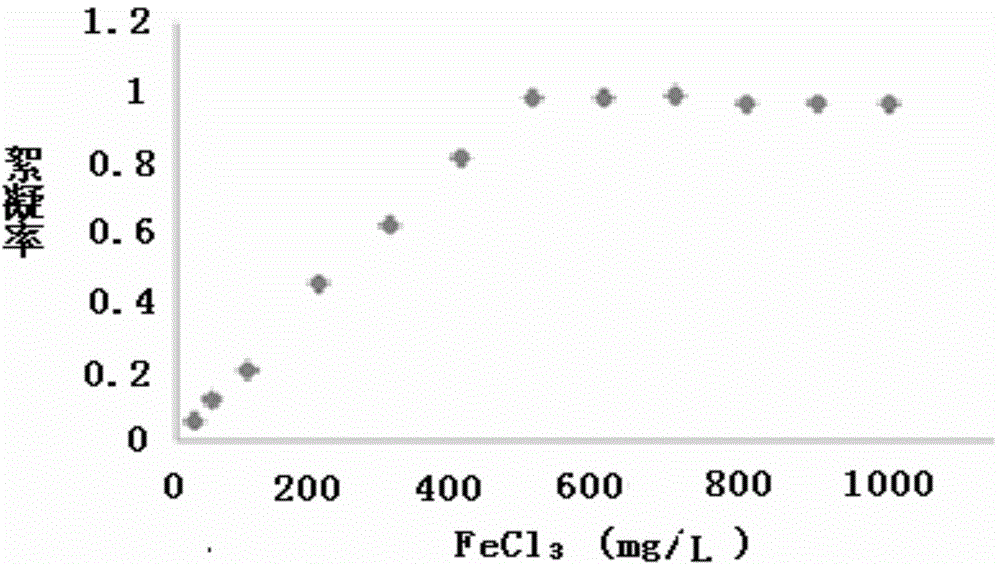

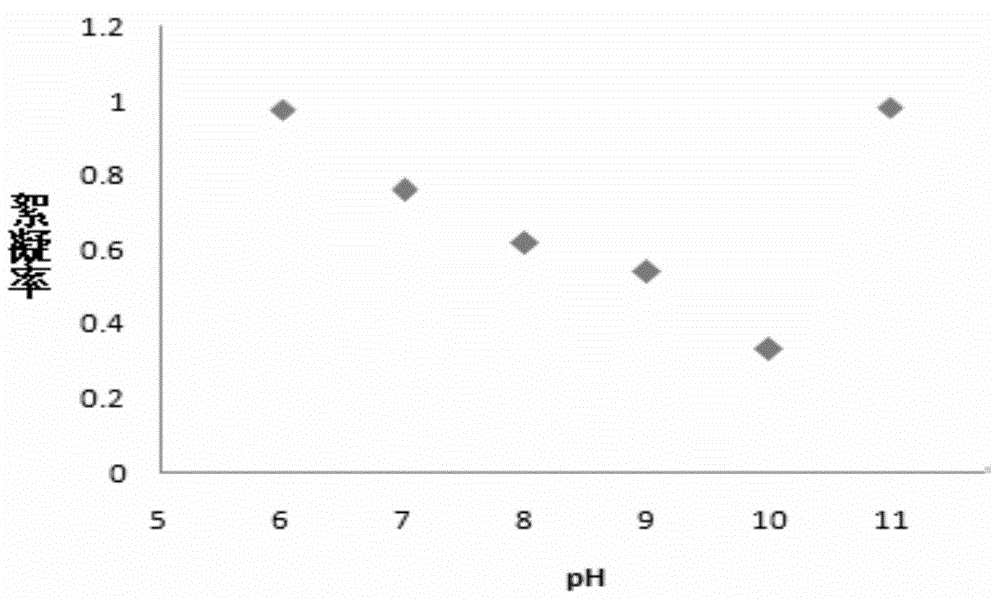

[0032] Configure flocculant mother liquor to make FeCl 3 .6H 2 O mother liquor concentration is 20g / L. The pH of the algae liquid obtained in Example 1 was adjusted with 1N NaOH or HCl solution, so that the pH of the algae liquid was 4, 5, 6, 7, 8, 9, 10, 11 and 12, respectively. Then, the FeCl 3 .6H 2 The O mother liquor was added to the above-mentioned algae liquors with different pH values to form flocculants with final concentrations of 0, 200, 400, 500, 600, 800 and 1000mg / LFeCl respectively. 3 63 different treatments, the results show that at pH 6, FeCl in algae liquid 3 When the final concentration was 500mg / L, the flocculation efficiency of Chlorella algae was the highest, reaching 98% (see figure 1 , figure 2 ), at the same time, when the pH is 11, the FeCl in the algae liquid 3 When the final concentration is 500mg / L, the flocculation efficiency of Chlorella algae also reaches 98%, and the effect is eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com