A kind of epoxy resin containing phenolic hydroxyl group and preparation method of flame-retardant foaming material thereof

A technology of novolac epoxy resin and epoxy resin, which is applied in the field of preparation of epoxy foam, novolac epoxy resin and its foam materials, can solve the problems of low mechanical strength, easy to drop slag and powder, use restrictions, etc., and achieve improvement Effects of cross-linking density, increased reactivity, and uniform foam density distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

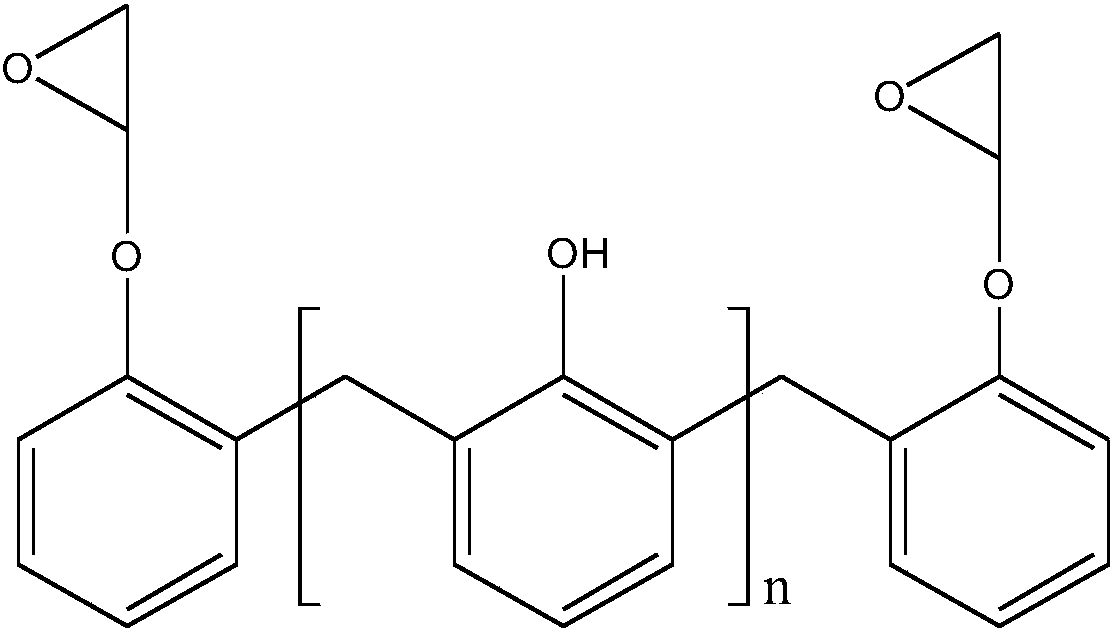

[0032] A kind of synthesis that contains the epoxy resin of phenolic hydroxyl group, comprises the following steps:

[0033] Add 100g of phenol and 28.7g of paraformaldehyde into a three-necked flask, raise the temperature to 60°C, add 8.51g of NaOH (prepared as a 50% aqueous solution by mass fraction) to catalyze the addition reaction of phenol and formaldehyde, control the temperature at 60°C, and react 2 hour, then raise the temperature to 80°C, keep the heat for 4 hours, then add 109.57g epichlorohydrin at 60°C, control the temperature at 60°C, react until the epoxy resin is neutral, slowly add hot water (40- 50° C.) to wash the resin, and then distill off water and unreacted epichlorohydrin under reduced pressure to obtain an epoxy resin product containing phenolic hydroxyl groups.

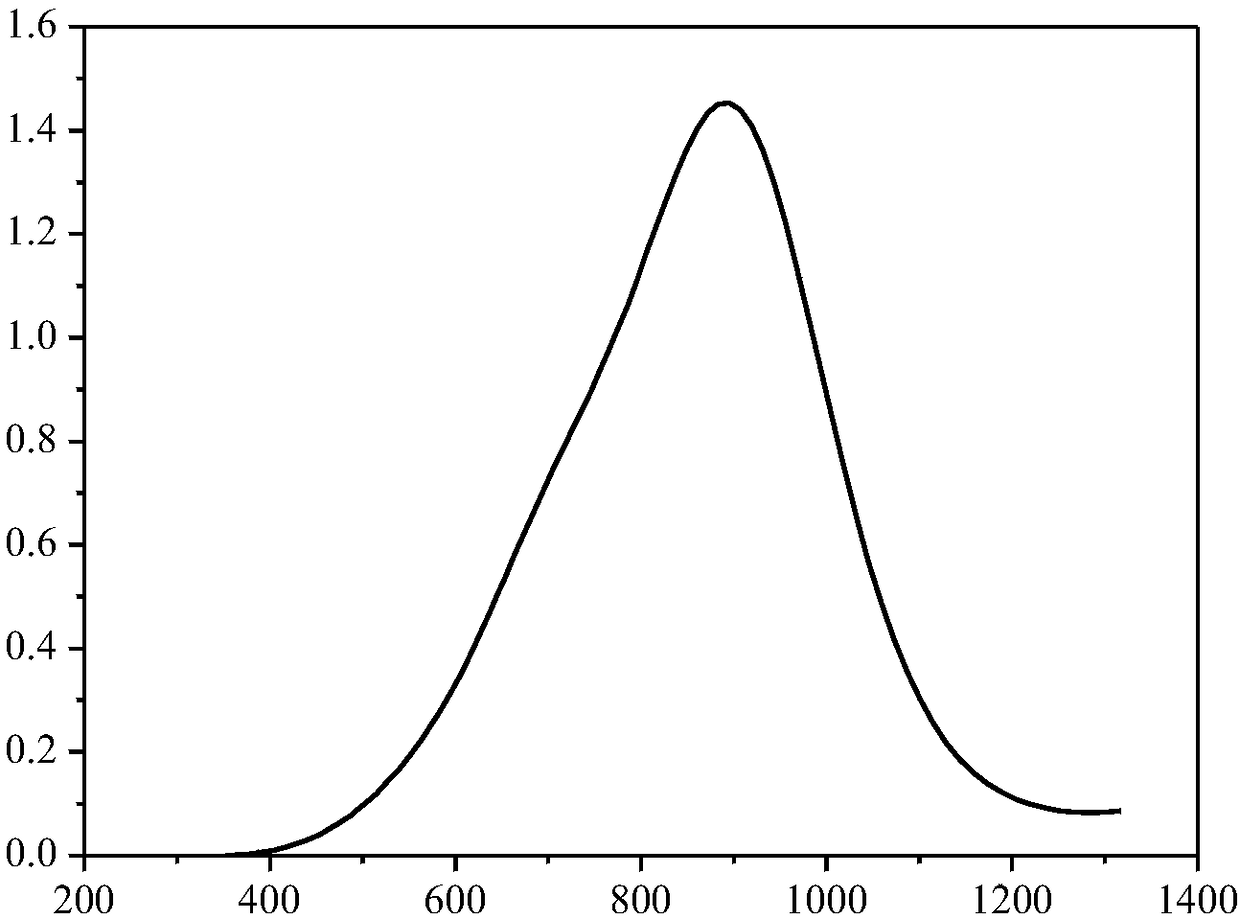

[0034] The technical parameters of the obtained epoxy resin product of phenolic hydroxyl group are: viscosity at 25° C. of 8600 mPa·S, solid content of 89.91%, and epoxy value of 0.31 mol / 100...

Embodiment 2

[0036] Prepare a kind of epoxy resin foam material containing phenolic hydroxyl based on embodiment 1 product, comprise the following steps:

[0037] Add 100g of the epoxy resin containing phenolic hydroxyl groups in Example 1, together with 5g Tween-80 and 6g petroleum ether, into the reactor and stir rapidly for 10min, then add 6g of diethylenetriamine curing agent, stir for 1min and then pour into Put it into a mold that has been preheated to 60°C, put it in an oven at 60°C and keep it warm for 2.5 hours, take it out and cool it to room temperature, and then demould to obtain an epoxy resin foam material containing phenolic hydroxyl groups.

[0038] Gained epoxy resin foam material containing phenolic hydroxyl group has even foam cells, and its technical parameters are: oxygen index 32.1%; foam density 0.15g / cm 3 ; Water absorption 3.27%.

Embodiment 3

[0040] A kind of synthesis that contains the epoxy resin of phenolic hydroxyl group, comprises the following steps:

[0041] Add 100g of phenol and 25.5g of paraformaldehyde into a three-necked flask, raise the temperature to 60°C, add 12.76g of NaOH (prepared as a 50% aqueous solution by mass fraction) to catalyze the addition reaction of phenol and formaldehyde, control the temperature at 60°C, and react for 2.5 hour, then raise the temperature to 80°C, heat preservation reaction for 4 hours, then add 98.62g epichlorohydrin at 60°C, control the temperature at 60°C, react until the epoxy resin is neutral, slowly add hot water (40- 50°C) to wash the resin, and then distill off water and unreacted epichlorohydrin under reduced pressure to obtain an epoxy resin containing phenolic hydroxyl groups.

[0042] The technical parameters of the epoxy resin product of the obtained phenolic hydroxyl group are: viscosity at 25° C. of 9800 mPa·S, solid content of 90.62%, and epoxy value of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com