Method and system for preparing tips in different shapes by micro/nano capillary uniform-internal-diameter etching

A technology of capillary and equal inner diameter, which is applied in the field of micromachining, can solve the problems of individual differences in the shape of the inner diameter of the cone, and the difficulty of accurately calculating the pressure control of the liquid volume, so as to facilitate accurate sampling, realize the visualization of the sampling volume, and simplify the sampling pressure control process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The embodiment of the present invention provides a method and system for preparing tips with different shapes by etching micro-nano capillary tubes with equal inner diameters. The present invention will be described in detail by taking micro-nano capillary tip etching with an outer diameter of 150 μm and an inner diameter of 0.9 μm and live sampling of onion cells as examples. Description, the specific implementation steps are as follows:

[0061] Capillary tip etching

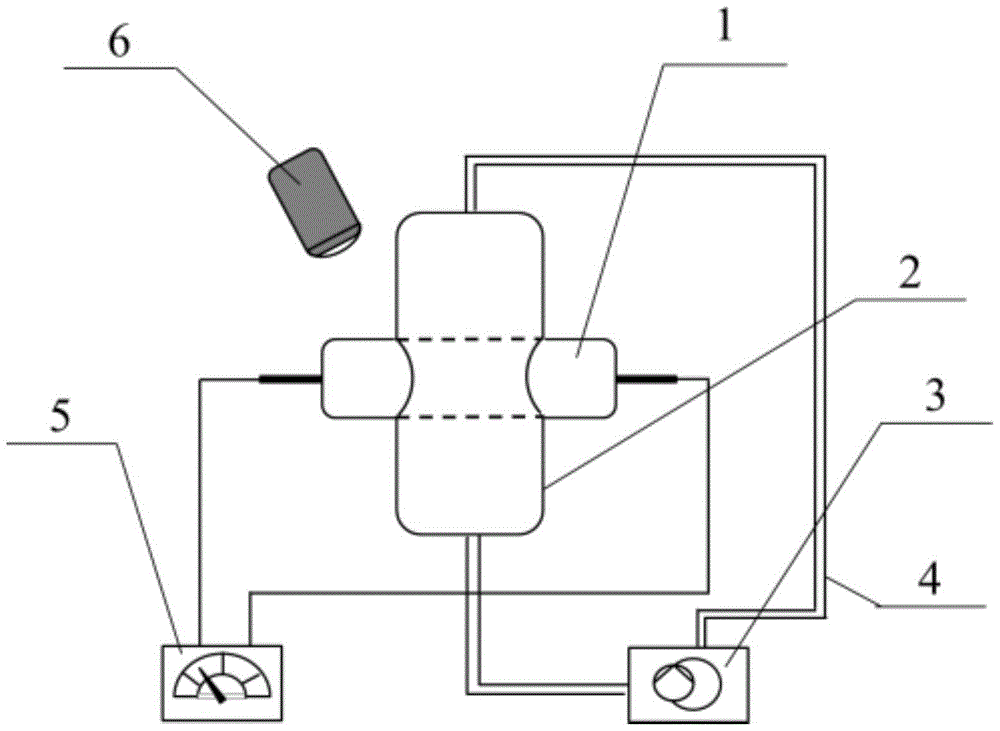

[0062] S1. A set of self-constructed capillary etching system includes a hydrofluoric acid etching chamber 1, a set of temperature-controlled water bath heating device 2, an internal air pressure control device 5, and a micromanipulation platform 6; (such as figure 1 shown)

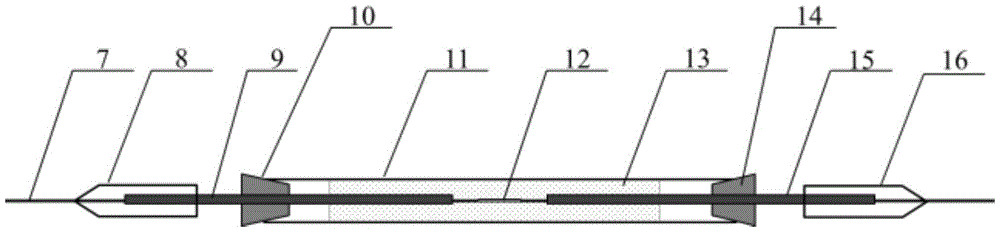

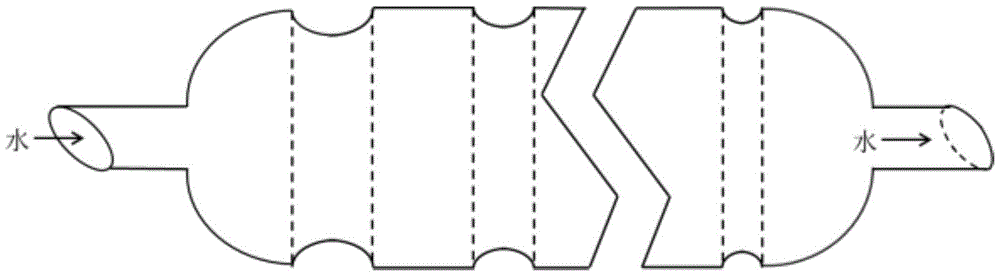

[0063] S2. Inject an appropriate amount of hydrofluoric acid 13 into the etching chamber through the peek tube 9, and add centrifuge tube water seal heads 8 and 16 respectively at the outer ends of the peek tube 9 and peek tube 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com