Automatic paper disassembling type insulation board forming machine

A board forming machine and the technology of the forming machine, applied in the field of automatic paper-removing type insulation board forming machine, can solve the problems of labor efficiency and other problems, and achieve the effects of improving production efficiency, improving carrying capacity and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

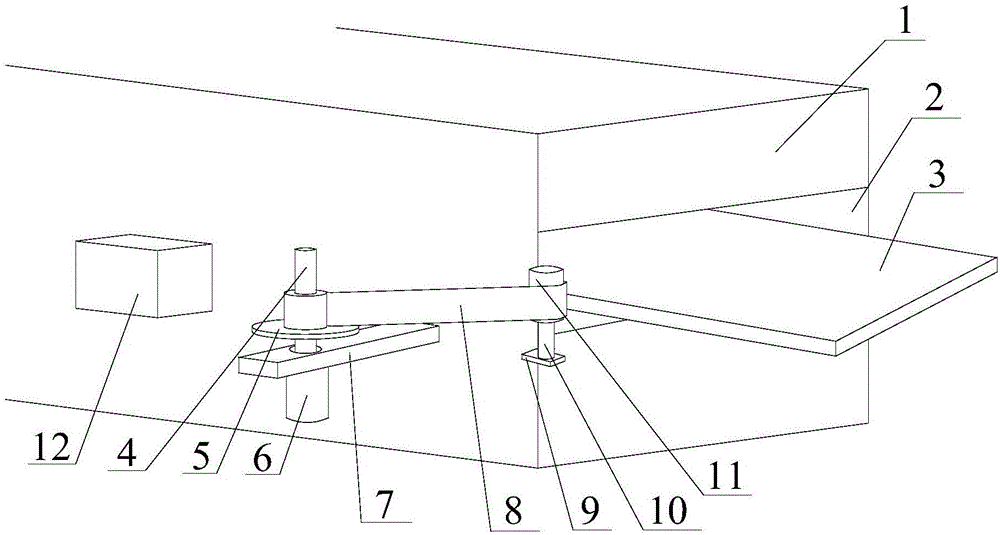

[0030] Such as figure 1 As shown, the insulation board molding machine of the present invention includes a molding machine main body 1, which is provided with an assembly line conveyor motor and a molding outlet 2. After the insulation board 3 is processed and formed inside the molding machine main body 1, the assembly line transmission belt motor works. And drive the belt to output the insulation board from the forming outlet 2. In order to facilitate the removal of the oil paper on both sides of the heat preservation board 3 after forming, an automatic paper removal device is provided on the main body 1 of the molding machine, and the automatic paper removal device is set to two, correspondingly removing the two sides of the heat preservation board 3 oiled paper, figure 1 The automatic paper unloading device on one side of the insulation board 3 is shown in , the automatic paper unloading device on the other side of the insulation board 3 is not shown, and the automatic pap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com