Multi-axis movement control method of industrial robot

An industrial robot and multi-axis motion technology, which is applied in the direction of program control of manipulators, manipulators, manufacturing tools, etc., can solve the problem that multiple axes of the robot cannot move synchronously, so as to facilitate reading information and ensure personal safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

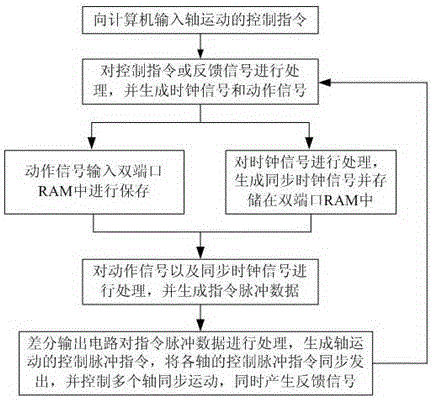

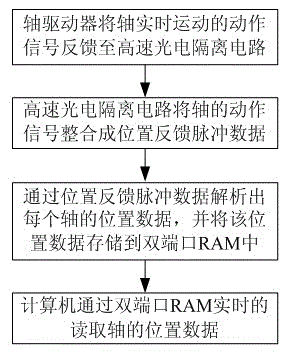

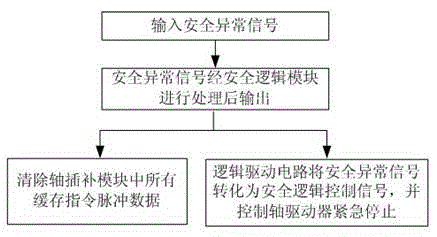

[0031] like Figure 1~3 As shown, the present invention mainly controls the simultaneous movement of multiple axes of industrial robots, and its flow process is as follows figure 1 shown. First of all, the user needs to pre-set the control command of the axis movement, so that each axis of the industrial robot will act according to the pre-set command. The user inputs the set control command into the computer, and the computer processes the control command and generates a clock signal and an action signal for controlling the movement of the shaft. The motion signal includes position data and motion speed data for controlling the motion of the axes, so that each axis of the robot moves according to the clock signal and the motion signal.

[0032] The action signal is sent to the dual-port RAM through the bus driver IC for storage, and the clock signal is sent to the clock management unit through the bus driver IC. The clock management unit processes the clock signals of multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com