Bracing wire type hanging and folding screen

A wire-pulling, sieve-chamber technology, applied in the field of laboratory analysis tools, can solve the problems of sticking to mud, high cost, uncomfortable hand, etc., and achieves the effect of low noise and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

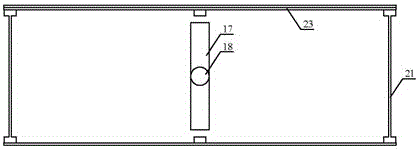

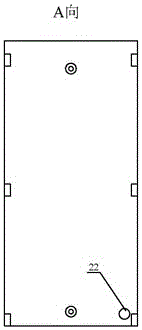

[0051] Such as figure 1 , 2 , Shown in 3 and 4, a kind of backguy type hangs folding sieve with test, comprises sieve cavity assembly, sieve box 21 and backguy mechanism;

[0052] The sieve cavity assembly includes an upper static cavity 11, an upper swing sieve cavity 12, a shaking sieve cavity 13, a lower swing sieve cavity 14, and a lower static cavity 15 from top to bottom, and each cavity is surrounded by surrounding sides. Hollow communication structure, and are movable connection with each other; among them, the left and right sides of each sieve cavity are provided with screen frame and screen 16, and the front and rear sides of each sieve cavity are folded; the top of the upper static cavity 11 is provided with a shrinking plate 17 , there is an inlet and outlet opening 18 above the necking plate 17;

[0053] The fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com