Automatic spraying robot for overhead transmission line

An overhead transmission line, automatic spraying technology, applied in the direction of spraying devices, etc., can solve the problems of damage to the power line, poor working reliability, and failure to press

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

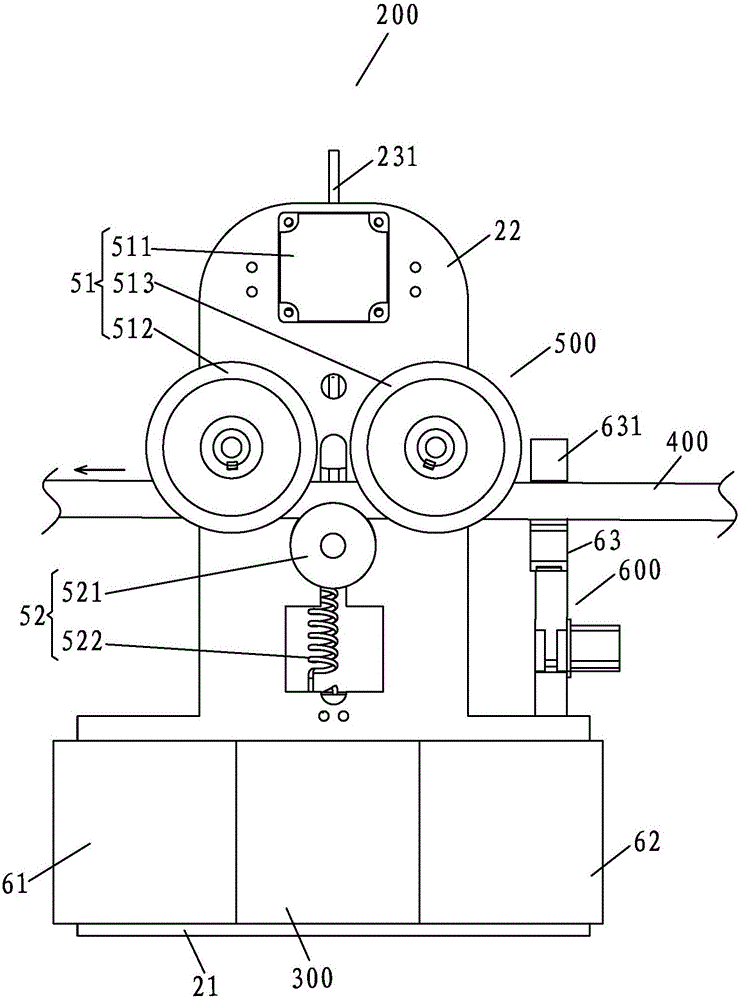

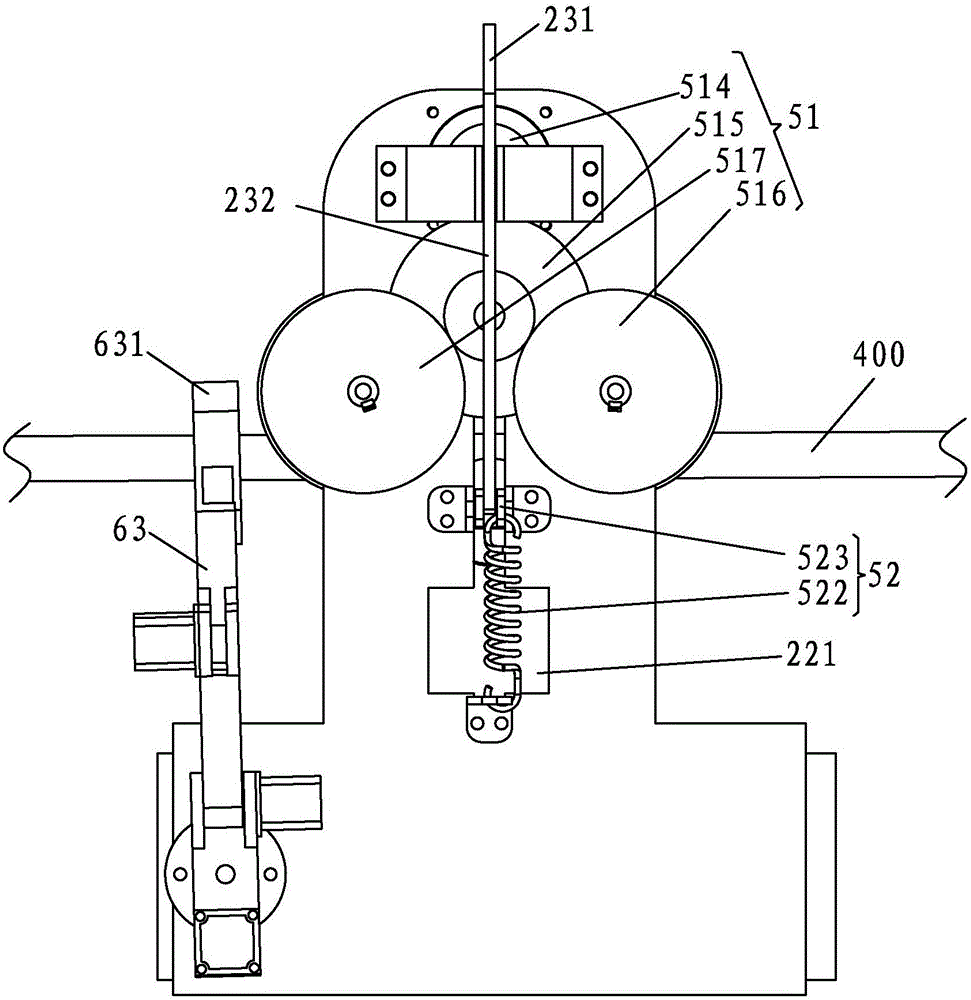

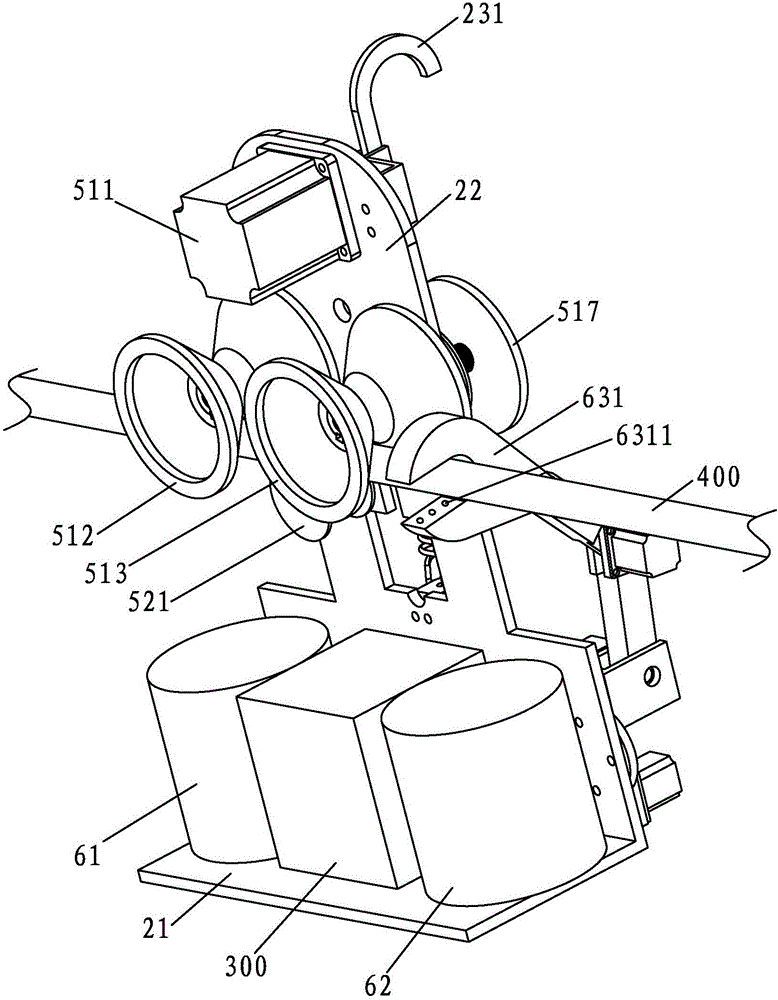

[0030] The overhead transmission line automatic spraying robot of the present invention, as Figure 1-5 As shown, it includes a control system 100 and a mobile body 200. The control system 100 includes a ground control system 11 and an airborne control system 12 arranged on the mobile body 200. The airborne control system 12 is realized by a wireless data transmission unit and the ground control system 11. Data interaction and communication.

[0031] The mobile body 200 is also provided with a storage battery 300 , a running system 500 for driving the mobile body 200 to travel on the overhead power transmission line 400 , and a spraying system 600 for spraying insulating varnish on the overhead power transmission line 400 . The battery 300 supplies power to the traveling system 500 , the spraying system 600 and the onboard control system 12 ; the onboard control system 12 controls the work of the traveling system 500 and the spraying system 600 .

[0032] The mobile body 200 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com