Discharge screening device for ball mill

A technology of ball mill and discharge sieve, which is applied in the direction of grain processing, etc., can solve the problems of the screening circuit being mixed into the cylindrical sieve and affecting the working efficiency of the process, so as to improve the separation ability, improve the grinding and screening function, and improve the working efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

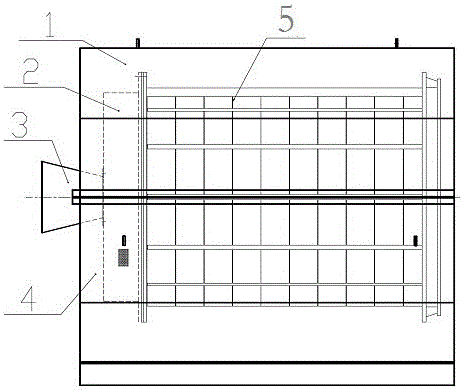

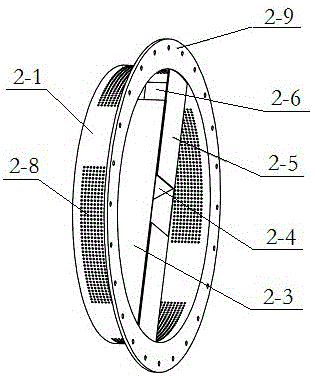

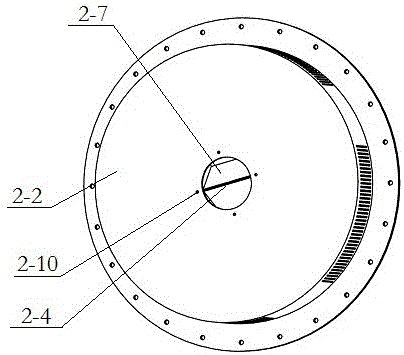

[0021] As shown in the figure, a discharge screening device for a ball mill includes a cylindrical screen 5, a waste discharge screen 2, a bell mouth 3 and a protective cover. The cylindrical screen 5 rotates together with the mill cylinder to discharge The waste sieve 2 includes a cylindrical sieve body 2-1, one end of the cylindrical sieve body 2-1 is open and the other end is closed by a baffle 2-2, wherein the cylindrical sieve body 2-1 of the waste sieve 2 The open end is connected to the discharge end of the cylindrical screen 5 through the flange I2-9, the bell mouth 3 is set outside the cylindrical screen body 2-1, and the narrowing end of the bell mouth 3 passes through the flange II3-1 Connected to the discharge port 2-7, the baffle plate 2-2 around the discharge port 2-7 is provided with a number of bolt holes 2-10 for fixing the flange II 3-1. The baffle plate 2-2 is provided with a discharge port 2-7, the discharge port 2-7 is a circular hole and is located at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com