Synchronous gap adjusting and locking mechanism of particle molding machine

A gap adjustment and forming cavity technology, which is applied in the direction of mold extrusion granulation, solid fuel, biofuel, etc., can solve the problem that the positional relationship between the eccentric shaft and the ring die is difficult to ensure, the life of the forming die and pressure roller is reduced, and the die cannot be changed. Roll gap size and other issues, to achieve the effect of easy adjustment of die roll gap, improve working life and reduce deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

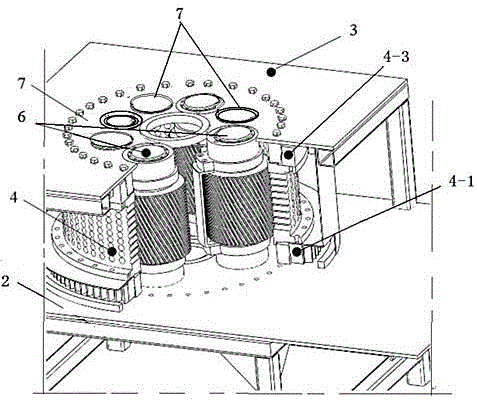

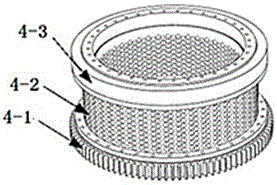

[0017] See Figure 1-5 , four groups such as image 3 The shown concentric straight shaft press roller assembly 6 is vertically installed on figure 2 In the shown ring mold assembly 4, the inner cavity of the ring mold assembly 4, the upper cover plate 3 of the molding cavity and the lower cover plate 2 of the molding cavity supported by the frame 1 form a material molding cavity; the upper cover plate 3 of the molding cavity A plurality of evenly distributed feeding ports 7, the material is filled by multiple feeding ports 7; a set of pressure roller assembly 6 is installed between every two feeding ports, and the inner surface of the ring die 4-2 and each pressure roller 6 A wedge-shaped compression area is formed between the largest outer circular surfaces of -1, which compresses the fed biomass material from a loose state to a densely formed consolidated state, and is extruded from the die hole on the ring die 4-2 to form shaped particles .

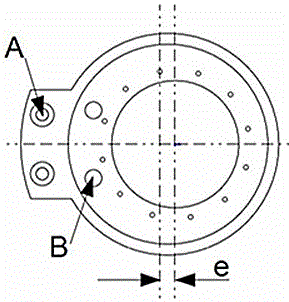

[0018] See Figure 4 , 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com