High-protein brown yoghourt and preparing method thereof

A high-protein, brown technology, applied in the field of high-protein brown yogurt and its preparation, can solve the problems of low protein content, single color, unfavorable healthy diet, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

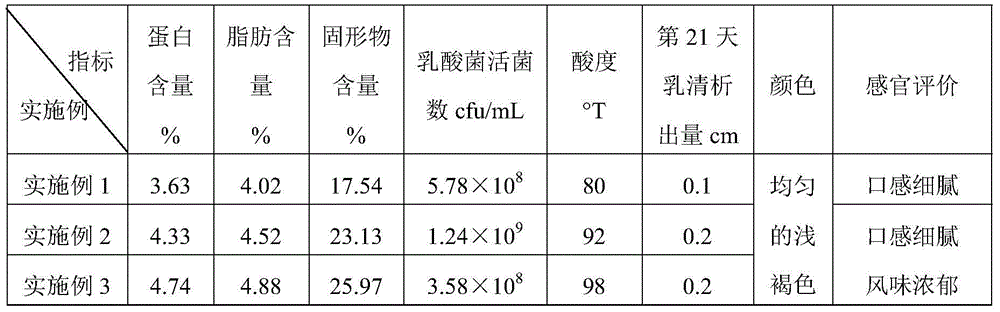

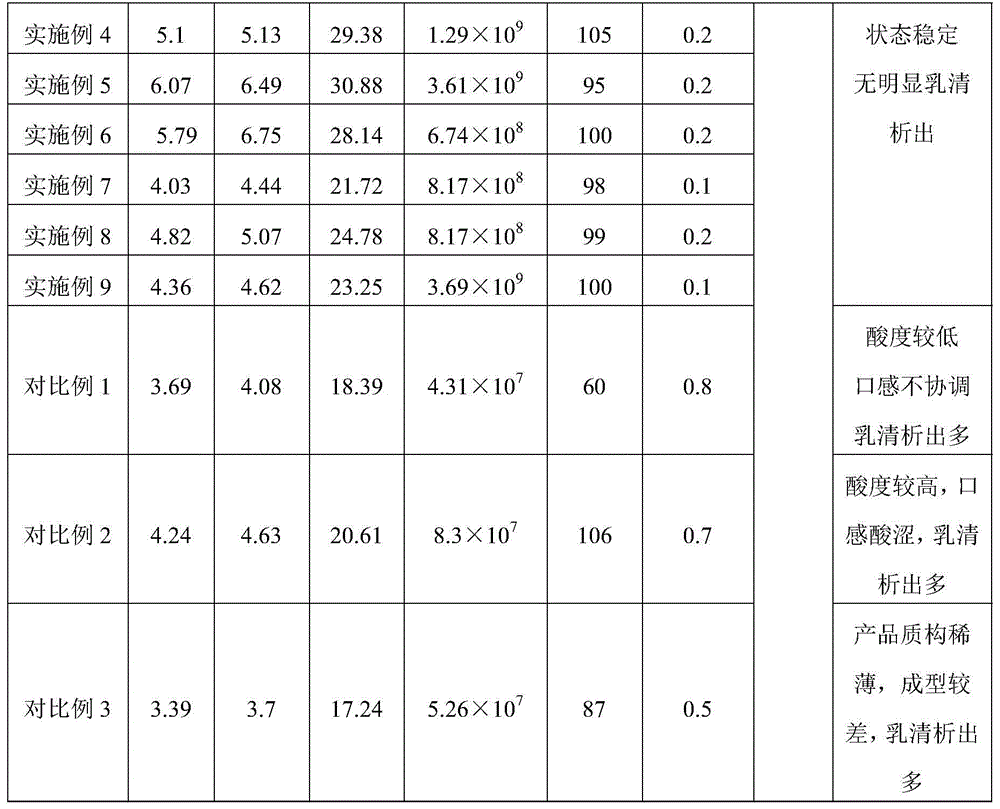

Examples

Embodiment 1

[0044] (1) Concentrating raw milk to obtain processed milk, the specific operations are as follows;

[0045] After the raw milk has passed the inspection, it is preheated and flash-evaporated with a vacuum degree of 0.06MPa and an evaporation temperature of 65°C to obtain processed milk with a protein content of 3.8% and a fat content of 4.21%.

[0046] (2) Preheat processed milk to 45°C, mix and stir with fructose syrup (F42 model) and inulin for 10 minutes to obtain a uniform mixture liquid; after homogenization, sterilization, browning, cool to 36°C through a plate heat exchanger ℃, to obtain brown milk;

[0047] Among them, the addition of fructose syrup (F42 model) is 4%; the addition of inulin is 0.5%, and the above percentages are all relative to the mass percentage of processed milk; homogeneous conditions: temperature is 60 ° C, primary pressure is 3MPa, secondary pressure 17MPa; sterilization conditions: temperature 90°C, heat preservation 10min; browning conditions...

Embodiment 2

[0051] (1) Concentrating raw milk to obtain processed milk, the specific operations are as follows;

[0052] After the raw milk has passed the inspection, it is preheated and concentrated by a plate evaporator with a vacuum degree of 0.07MPa and a heating temperature difference of 25°C to obtain processed milk with a protein content of 4.6% and a fat content of 4.8%.

[0053] (2) Preheat the processed milk to 50°C, mix and stir with glucose and fructooligosaccharide for 12 minutes to obtain a uniform mixture liquid; after homogenization, sterilization, browning, and cool to 37°C through a tubular heat exchanger, brown milk is obtained liquid;

[0054] Among them, the amount of glucose added is 5%; the amount of fructooligosaccharide added is 0.8%, and the above percentages are relative to the mass percentage of processed milk; homogeneous conditions: temperature is 75°C, primary pressure is 5MPa, secondary pressure 25MPa; Sterilization conditions: temperature 105°C, heat pres...

Embodiment 3

[0058] (1) Concentrating raw milk to obtain processed milk, the specific operations are as follows;

[0059] After passing the inspection, the raw milk is preheated and concentrated by the single-effect falling film process. The sterilization temperature is 86°C, the steam pressure is 0.6MPa, the first-effect evaporation temperature is 60°C, and the first-effect heating temperature is 70°C; the protein content is 5.1%, and the fat content 5.25% processed milk;

[0060] (2) Preheat processed milk to 48°C, mix and stir with fructose and galacto-oligosaccharide for 10 minutes to obtain a uniform mixture liquid; after homogenization, sterilization, browning, cool to 38°C through a plate heat exchanger to obtain brown Milk;

[0061] Among them, the addition of fructose is 6%; the addition of galacto-oligosaccharide is 1%, and the above percentages are relative to the mass percentage of processed milk; homogeneous conditions: temperature is 70°C, primary pressure is 4MPa, secondary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com