Slide ring seal arrangement with improved outflow behaviour for a cooling and/or barrier medium

A technology of mechanical seals and mechanical seals, applied in mechanical equipment, engine components, engine seals, etc., can solve problems such as fluid flow loss, achieve low-loss flow, and improve cooling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

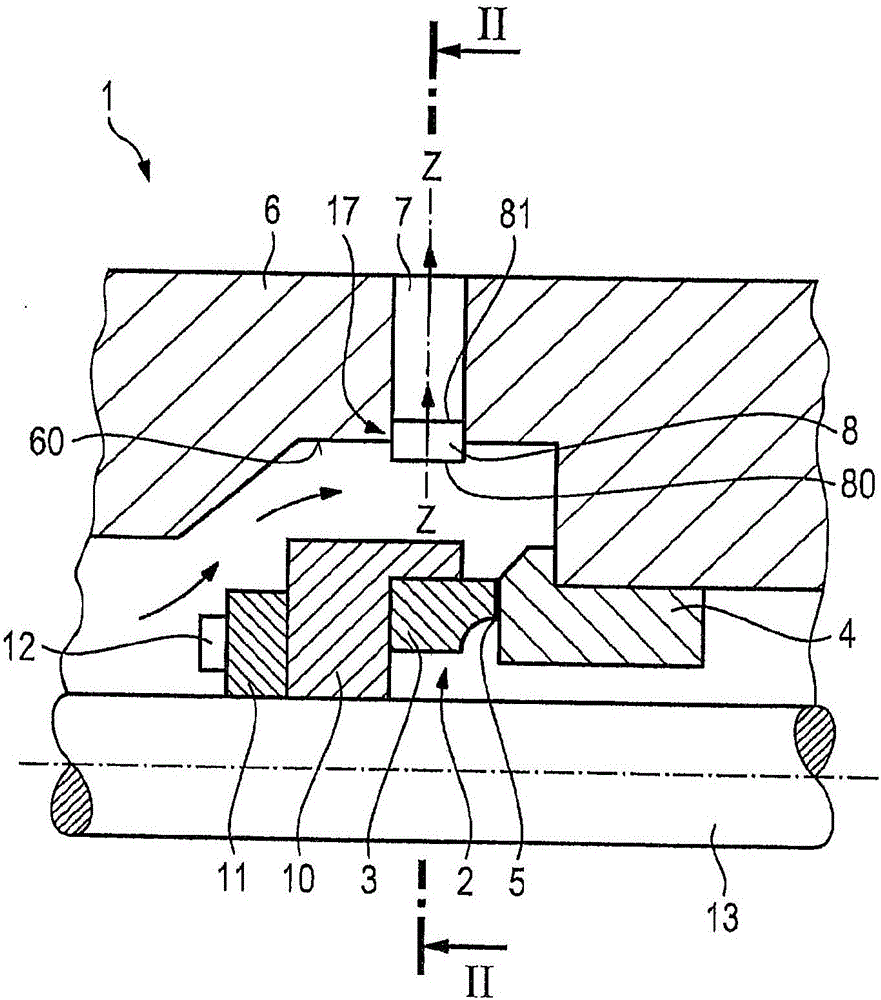

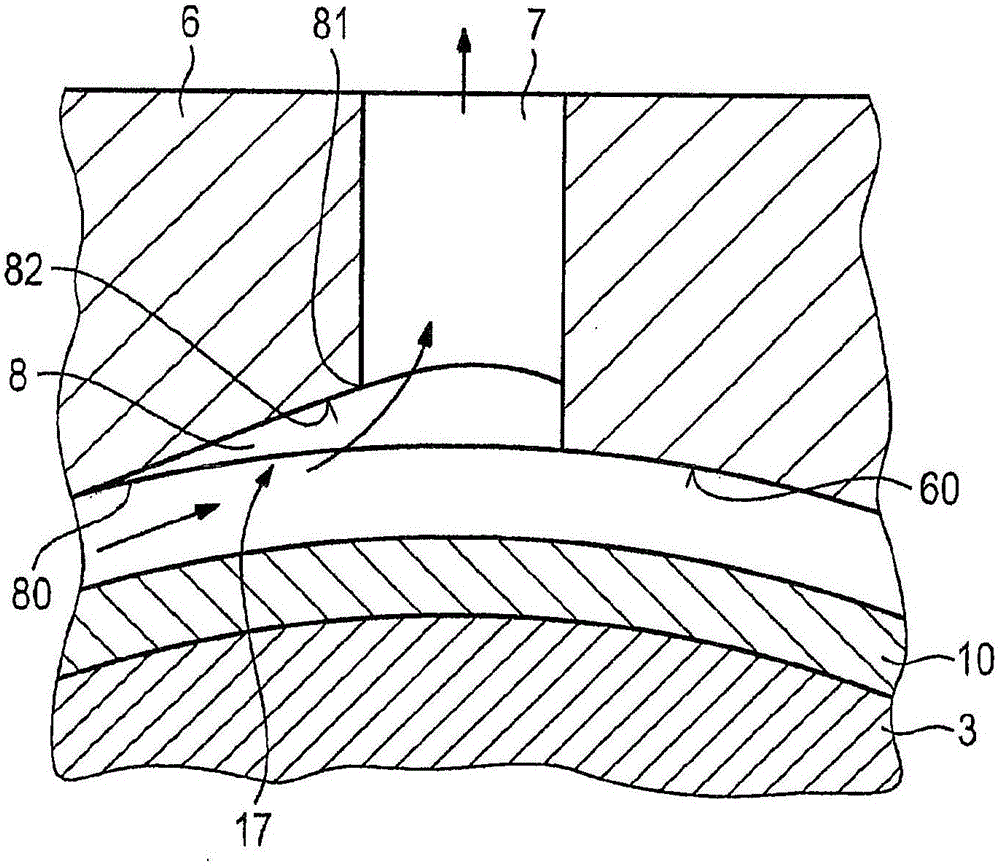

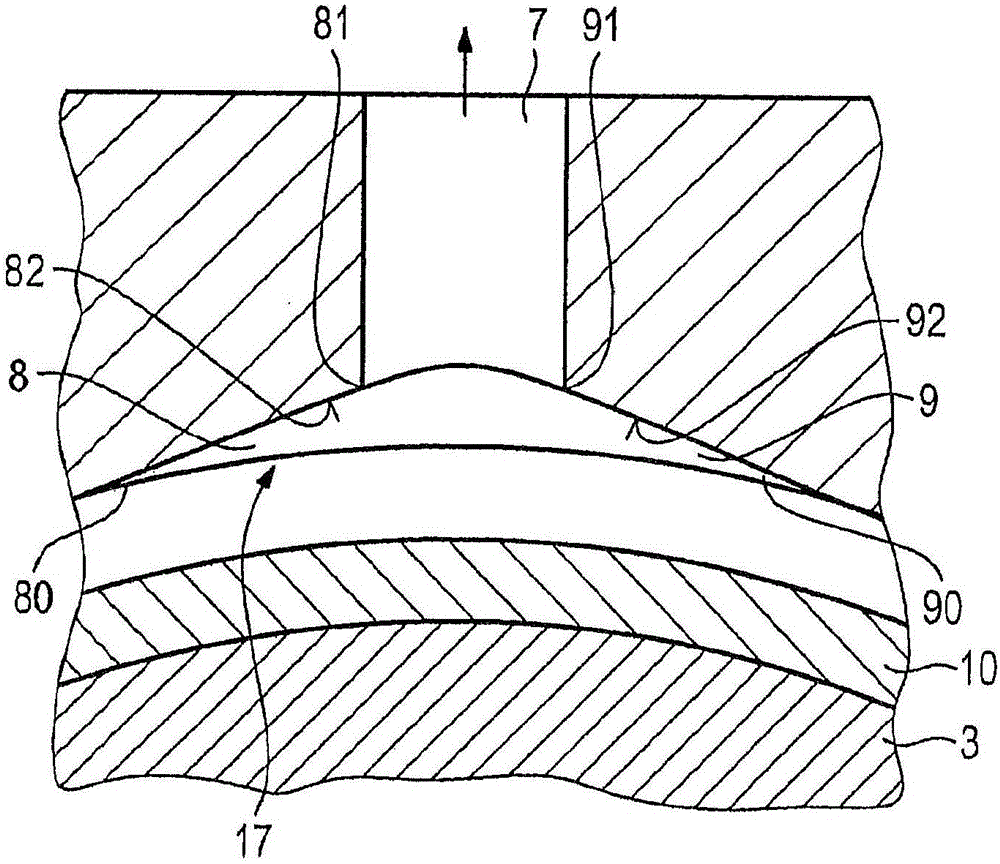

[0022] The following will refer to figure 1 and figure 2 The mechanical seal device 1 according to the first exemplary embodiment of the present invention is explained in detail.

[0023] Such as figure 1 As shown, the mechanical seal device 1 includes a mechanical seal 2 with a rotating slip ring 3 and a stationary slip ring 4 . The two slide rings define a sealing gap 5 between them.

[0024] The fixed slip ring 4 is fixed to the housing assembly 6 .

[0025] The rotary slip ring 3 is connected to a shaft 13 via an entrainment element 10 . The transmission element 10 thus transmits the torque from the shaft 13 to the rotary slip ring 3 .

[0026] Furthermore, an internal conveying device 11 with blades 12 is arranged on a shaft 13 . The internal delivery device 11 rotates together with the shaft 13 and serves to deliver fluid to the mechanical seal 2 . The fluid can be, for example, a sealing medium or a coolant. exist figure 1 and figure 2 Fluid flow is indicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com