Design method of single electric low-pressure reversing valve for deep-sea oil tree electro-hydraulic control valve group

A technology of electro-hydraulic control valve and deep-sea oil tree, which is applied in the direction of calculation, valve device, valve details, etc. It can solve the problems of operation technical parameter error, low calculation efficiency, and insufficient operation stability of single electric low-pressure reversing valve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

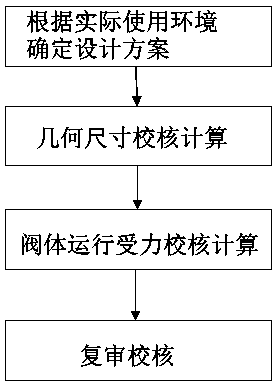

[0096] Such as figure 1 A design method for a deep sea tree electro-hydraulic control valve group single electric low-pressure reversing valve shown includes the following steps:

[0097] The first step is to determine the design scheme according to the actual use environment. According to the actual environment of the deep sea underwater operation of the valve body and the condition of the working medium, initially determine the applicable range of the effective working environment of the valve body, set various operating technical indicators of the valve body and The basic mechanical structure of the valve body;

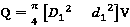

[0098] The second step is to check and calculate the geometric dimensions. According to the technical parameters of the valve body and the basic mechanical structure set in the first step, the geometric dimensions of the valve body are checked and calculated. The diameter of the hole and push rod, the minimum opening of the main valve port and the stroke of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com