A Method of Determining Optimal Printing Density

A technology of printing density and density, applied in the direction of instruments, specific gravity measurement, measurement devices, etc., can solve the problems of wasting materials and time, save materials and time waste, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

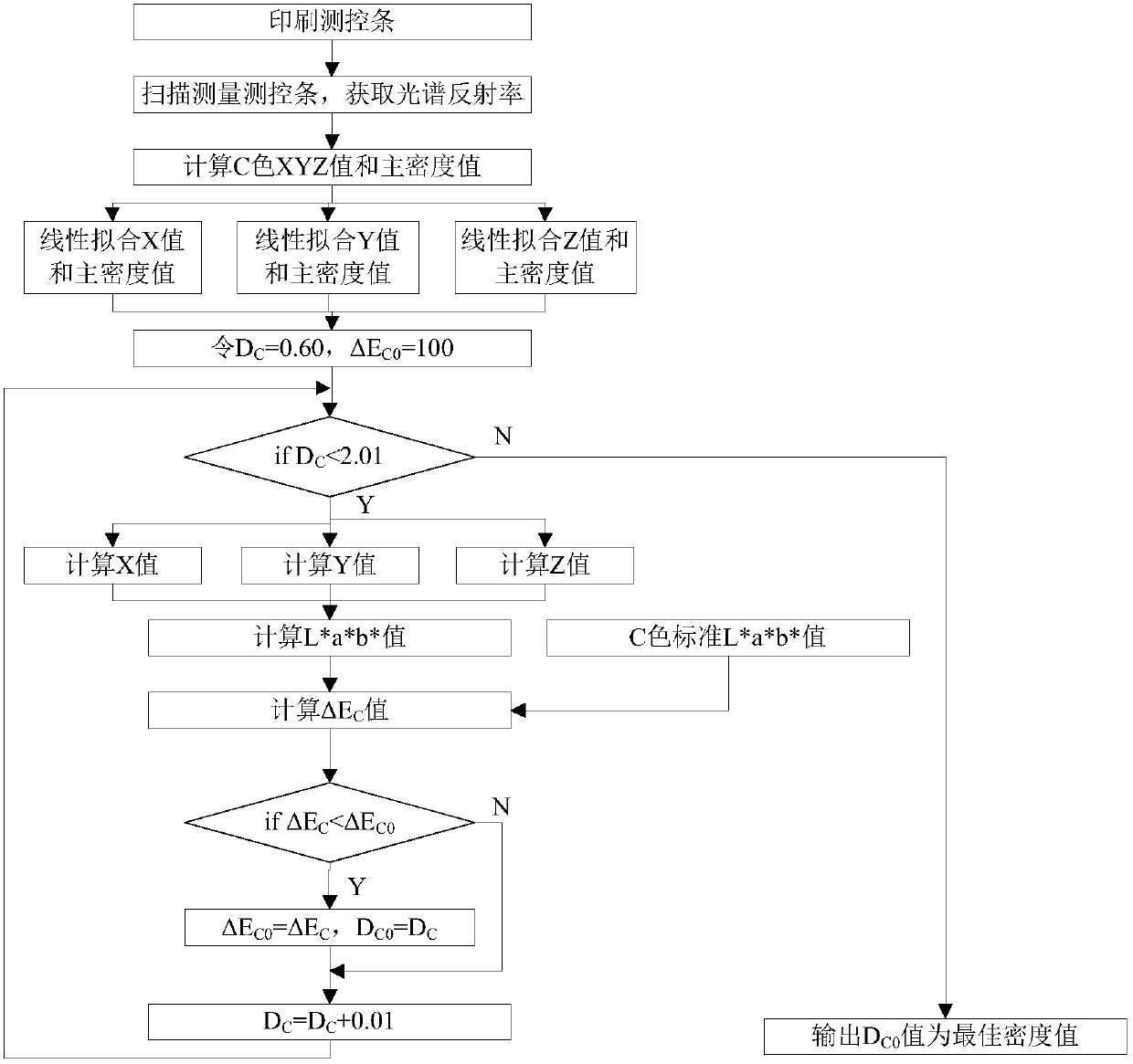

[0019] A method for determining the optimum printing density proposed by the present invention is to detect the cyan, magenta, yellow and black solid color patches in each ink area on the measurement and control strip in a scanning manner by adding a measurement and control strip to the printed sheet, and obtain the color patches of each color patch. Spectral reflectance value, calculate the main density value and tri-stimulus value, and get the relationship function between the main density value and tri-stimulus value of each color after fitting; then for the four colors of cyan, magenta, yellow and black, use The functional relationship between the tristimulus value and the main density, cyclically calculate the main density from 0.60, with 0.01 as the interval, until the tristimulus value and chromaticity value at 2.00, and then calculate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com