Calibration device for simulating friction moment of spaceflight bearing under zero gravity

A technology of friction torque and simulated weightlessness, which is applied to bearing-related force sensors, measuring devices, mechanical bearing testing, etc., can solve problems such as excessive starting friction torque, cage deformation and fracture, and poor operation, and achieve low cost , short development cycle and long weightlessness time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

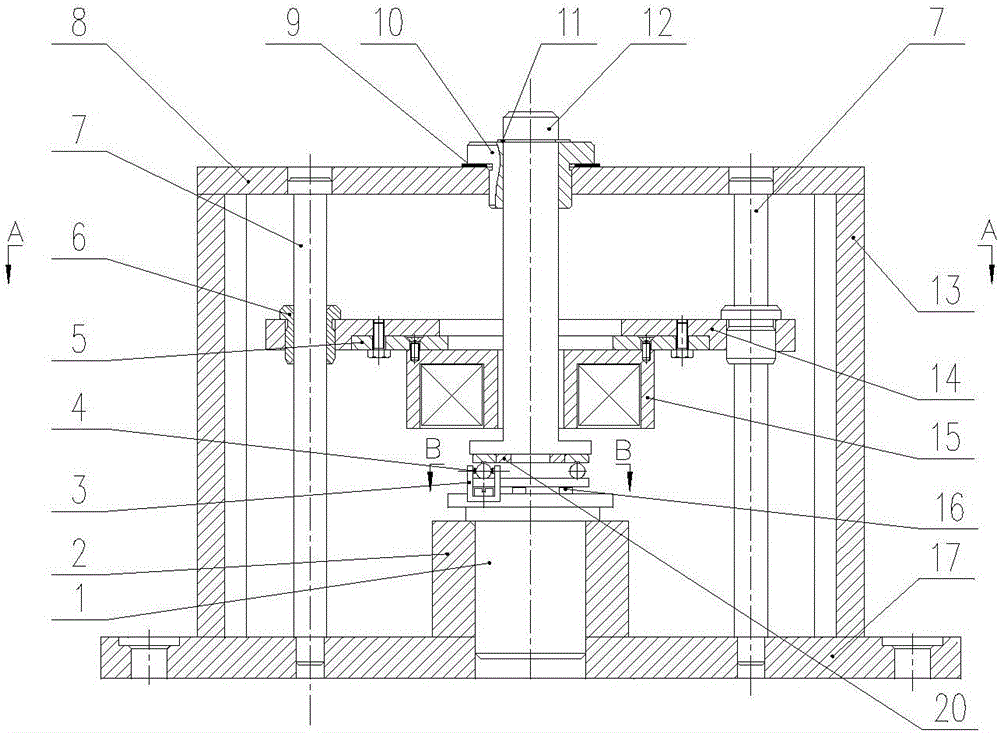

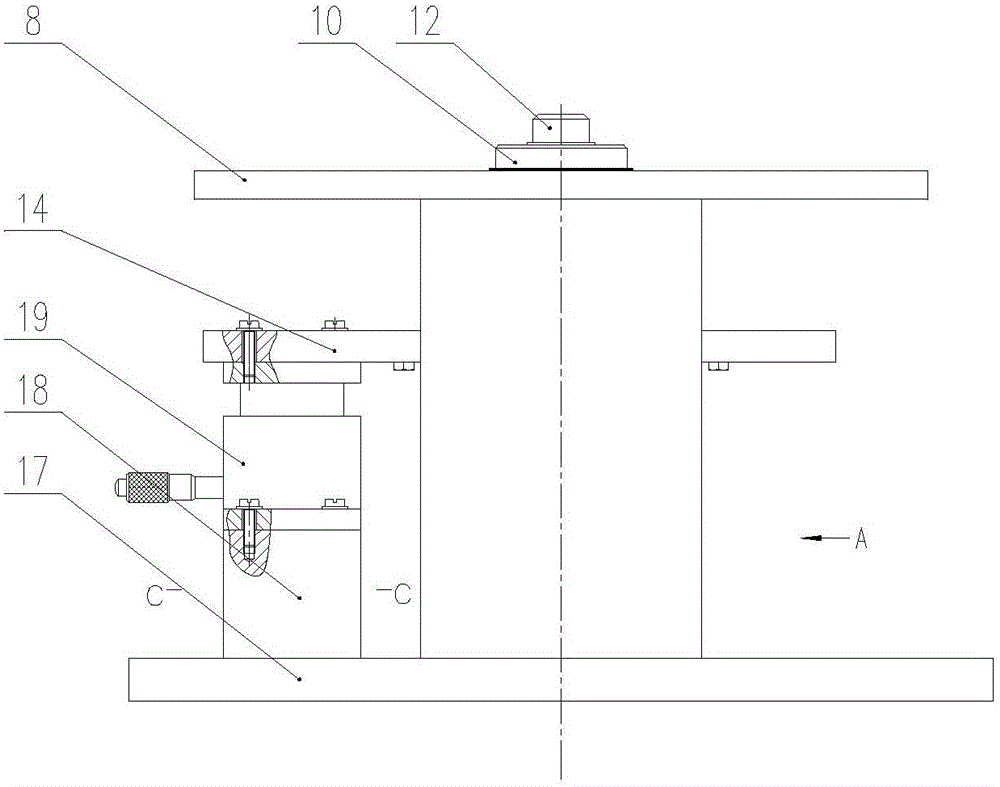

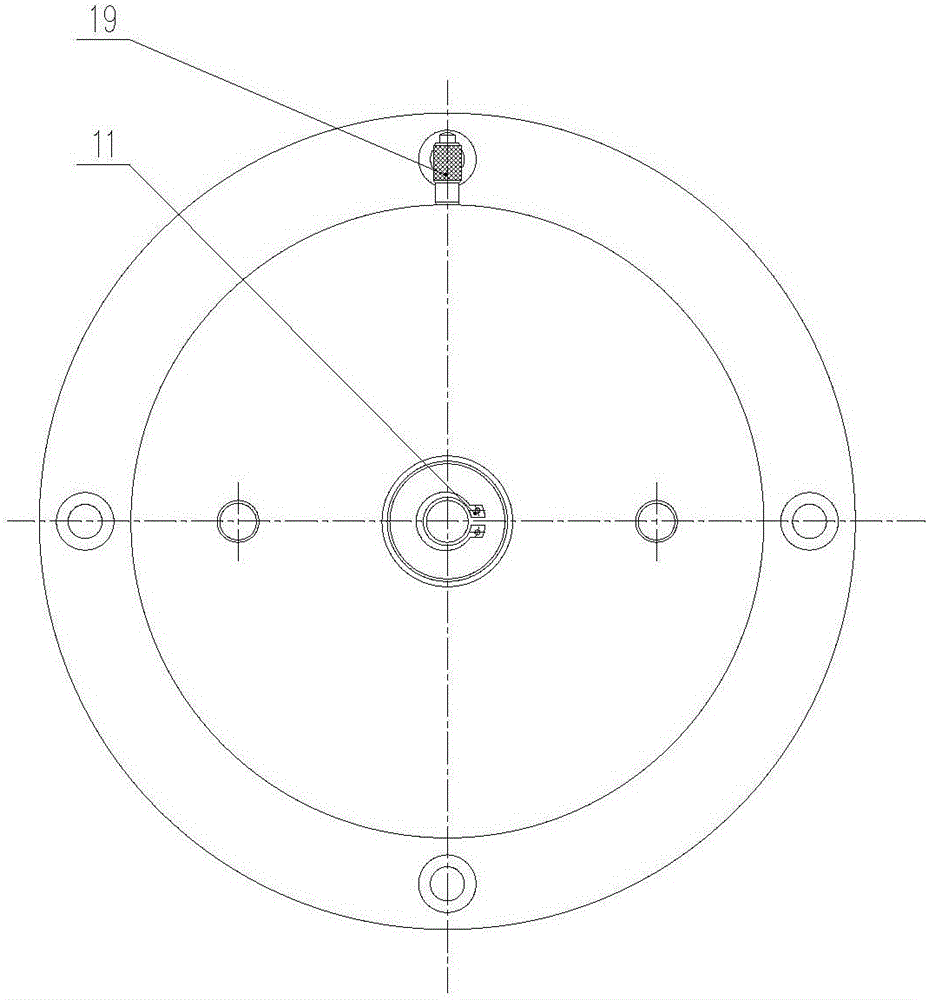

[0017] exist Figure 1 to Figure 7 In the schematic diagram of the present invention shown, the upper cover 8 and the lower cover 17 are connected through a column 13 and a guide rod 7 . The upper part of the lower cover is fixedly connected with the supporting seat 2, and the inside of the supporting seat is provided with a through hole, and the supporting platform 1 is placed inside the through hole of the supporting seat. The upper part of the support table is fixedly connected with the support frame 3 and the miniature pressure sensor 16 by screws, and the upper part of the support frame is provided with a fixed ultra-small flat pressure sensor 4 . The ball is placed in the middle of the ultra-small flat pressure sensor. The upper part of the miniature pressure sensor is provided with a shaft 12, and the lower end of the shaft is sleeved with a bearing sleeve 20, and the outside of the bearing sleeve is connected with the inner ring of the lower ring of the thrust ball be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com