Plane six-point calibration method of compass

A point calibration and compass technology, applied in the field of compass plane six-point calibration, can solve the problems of many acquisition points, long time consumption, poor flexibility, etc., and achieve the effect of high flexibility, simple application and easy realization.

Active Publication Date: 2016-06-29

710TH RES INST OF CHINA SHIPBUILDING IND CORP

View PDF3 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The eight-point calibration method requires fixed eight-point data on the carrier acquisition plane (the eight points are 0°, 45°, 90°, 135°, 180°, 225°, 270°, and 315°). Problems that take a long time and have poor flexibility

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0038]

[0039]

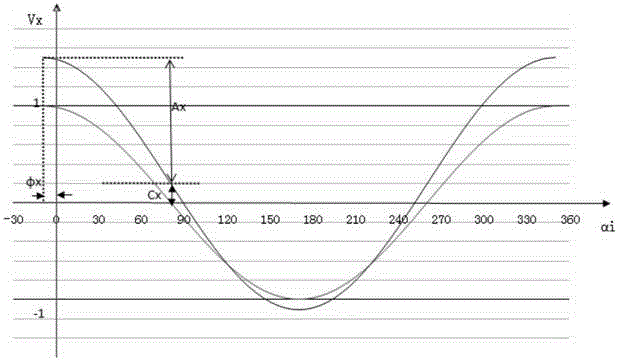

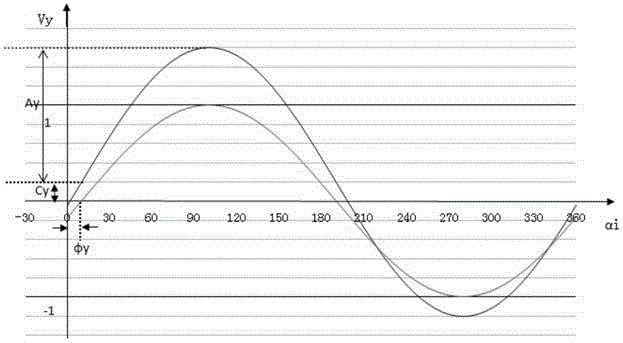

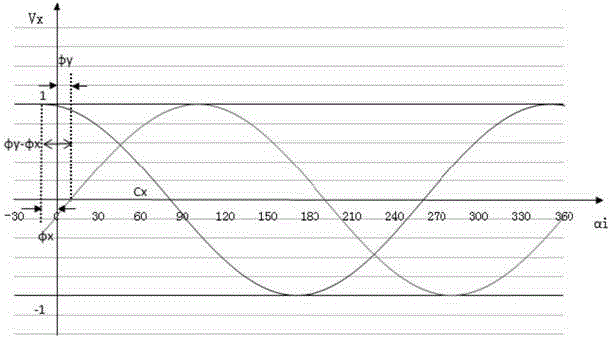

[0040] Bring in the following equations to calculate Ax, Cx, Ay, Cy and other 6 parameters.

[0041]

[0042] The result is A x =24000, C x =1216,A y =16000, C y =2343. Then H at different angles can be obtained x and H y , and then get the accurate azimuth output according to the azimuth calculation formula. The following are the calculated azimuths and errors.

[0043]

[0044]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a plane six-point calibration method of a compass. According to the method, a rotary table actually-measured angle serves as an independent variable, output of a magnetic sensor serves as a dependent variable, and a cosine curve function between the rotary table actually-measured angle and the X axis of the magnetic sensor and a sine curve function between the rotary table actually-measured angle and the Y axis of the magnetic sensor are constructed. In this way, only six unknown parameters exist in a formula, people only need to acquire data of six points at will, and a final azimuth angle can be obtained. The method is high in flexibility, easy to apply and easy to implement.

Description

technical field [0001] The invention relates to the field of magnetic azimuth calibration, in particular to a plane six-point calibration method of a compass. Background technique [0002] Magnetic navigation technology is widely used in navigation and positioning, geological exploration and other fields. Magnetic azimuth calibration technology is one of the core technologies of magnetic navigation technology. [0003] Since the compass needs a calibration process when it is first used, if it is not calibrated, the output angle of the compass will deviate from the actual angle; [0004] At present, the most commonly used plane calibration methods for compass are mainly circular calibration method and eight-point calibration method. The circular calibration method requires the carrier to rotate at a uniform speed to collect data, which has disadvantages such as a large amount of collected data, a basic uniform speed requirement, and the need to correct the zero position of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01C17/38

CPCG01C17/38

Inventor 童卫平李勇朱贵芳董昊齐侃侃

Owner 710TH RES INST OF CHINA SHIPBUILDING IND CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com