Helical ribbon vacuum dryer and working method thereof

A technology of vacuum dryers and ribbons, which is applied to non-progressive dryers, dryers, and drying solid materials, etc., can solve the problems of uneven heating, limited stirring, and low drying efficiency, so as to avoid material agglomeration , Facilitate fast drying and fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

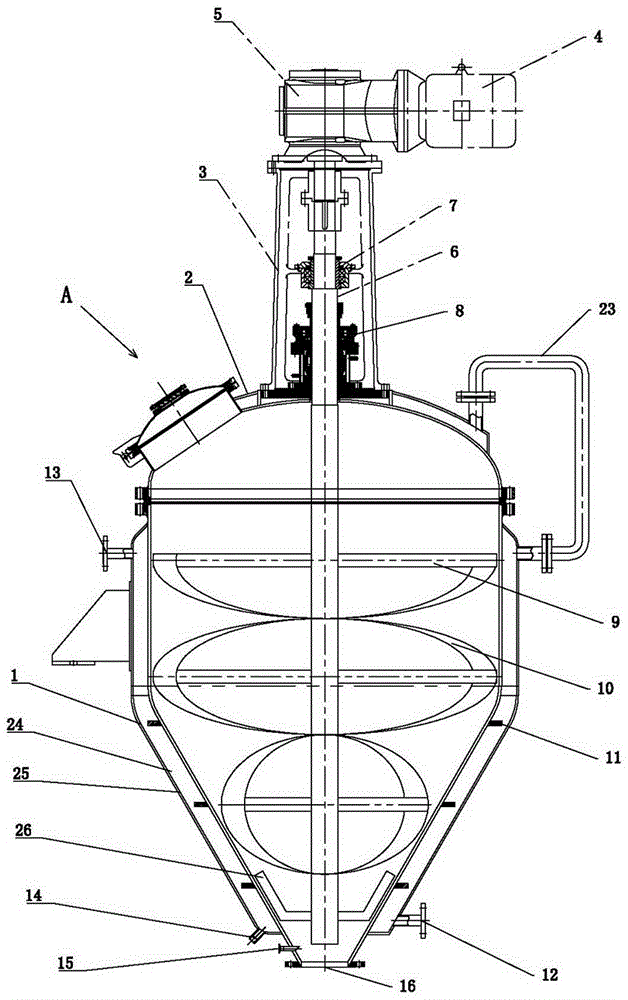

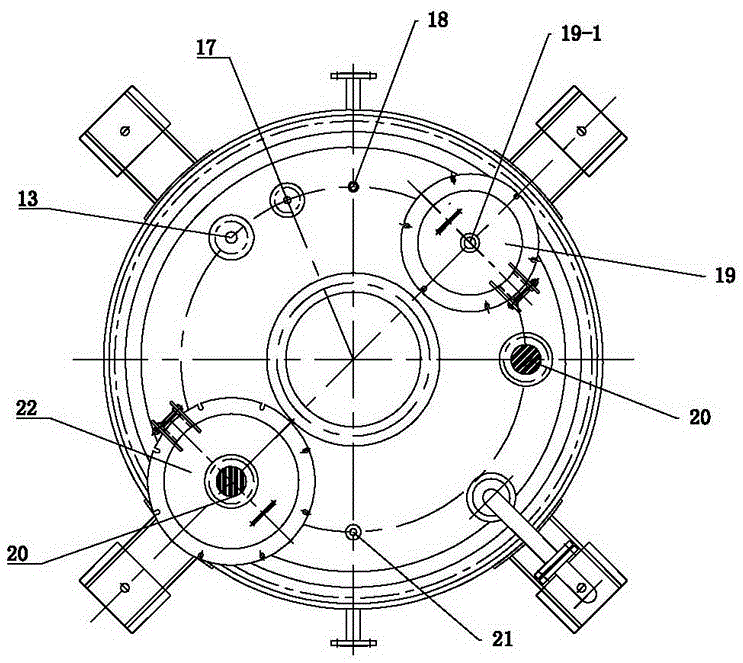

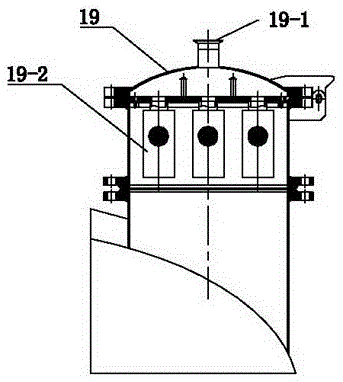

[0016] Such as figure 1 , figure 2 As shown, the ribbon vacuum dryer of the present invention includes: a mixing dryer A, which includes: a cylinder body 1, a cylinder cover 2, a bracket 3, a motor 4, a reduction box 5, a stirring shaft 6, a bearing 7, a mechanical seal 8, Support rod 9, double spiral belt 10, baffle plate 11, hot water inlet 12, hot water outlet 13, sewage outlet 14, nitrogen inlet 15, material outlet 16, spare port 17, thermometer port 18, manhole 19, pump Vacuum port 19-1, sight glass 20, vacuum port 21, feeding port 22, water pipe 23, jacket 24, insulation layer 25, scraper 26.

[0017] The upper part of the conical cylinder 1 is provided with a detachable cylinder cover 2, the upper part of the cylinder cover 2 is connected with a hollow bracket 3, the motor 4 and the reduction box 5 are installed on the top of the bracket 3, and the stirring shaft 6 is vertically installed on the bracket 3 through the bearing 7 The inside and the upper end are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com