Combustion cooking stove

A stove and burner technology, which is applied in the field of liquid fuel combustion stoves, can solve the problems of large consumption, weak firepower, and low vaporization efficiency, and achieve the effects of wide application range, fuel saving, and simple and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to further explain the technical solution of the patent of the present invention, the present invention will be described in detail below through specific examples.

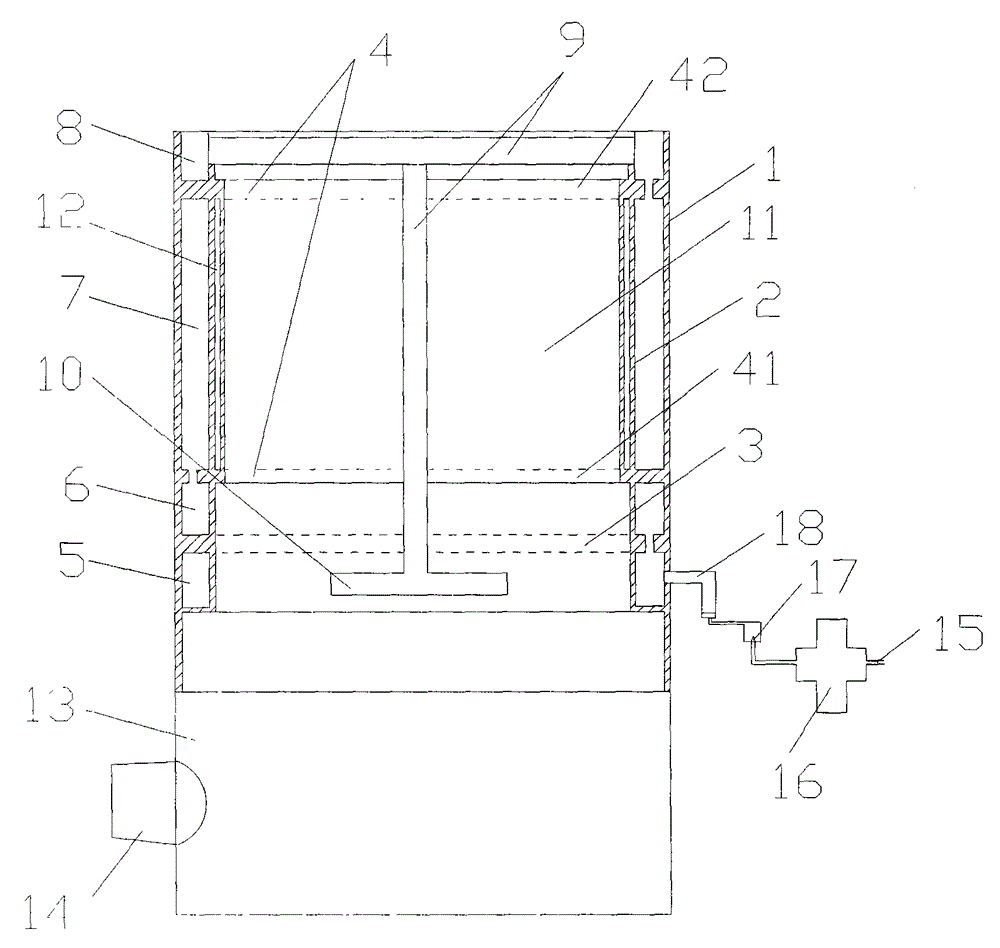

[0011] Such as figure 1 Shown, a kind of combustion stove, comprises furnace cover, pyrolysis burner head, oil inlet device; Said pyrolysis burner upper burner head outer wall 1 and burner head inner wall 2 are divided into liquid equalizing ring 3 and heat conduction ring 4 Chamber 5, preheating chamber 6, vaporization chamber 7, cracking chamber 8, said liquid equalizing chamber 5 communicates with preheating chamber 6 through the through hole on the liquid uniforming ring 3, and preheating chamber 6 passes through the through hole on the first heat conduction ring 41 The through hole is connected with the vaporization chamber 7, and then connected with the cracking chamber 8 through the through hole on the second heat conduction ring 42; The gas nozzle, the fuel gas nozzle is 45 degrees to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com