Combustion assembly of gas water heater

A technology for gas water heaters and components, which is applied to gas fuel burners, burners, combustion methods, etc., and can solve problems such as insufficient combustion and low energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

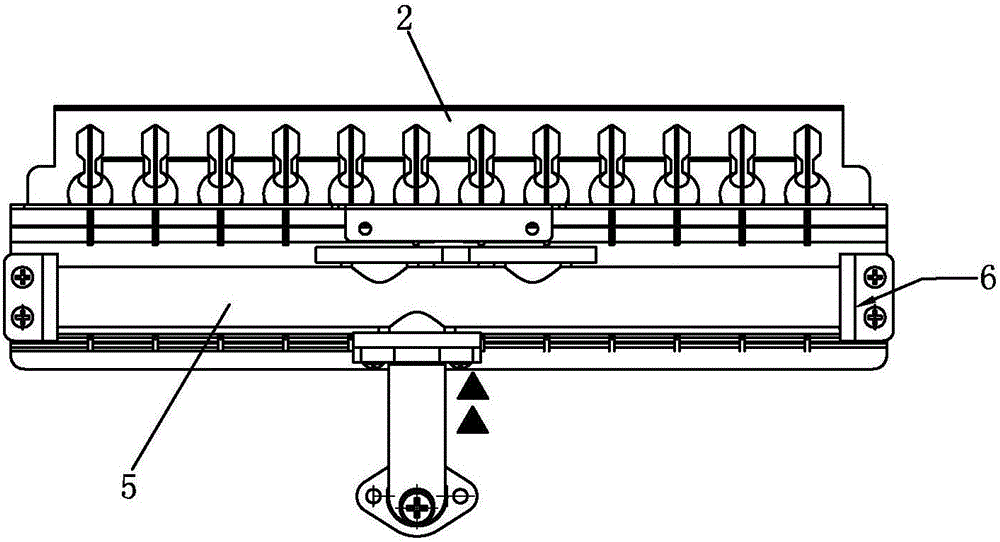

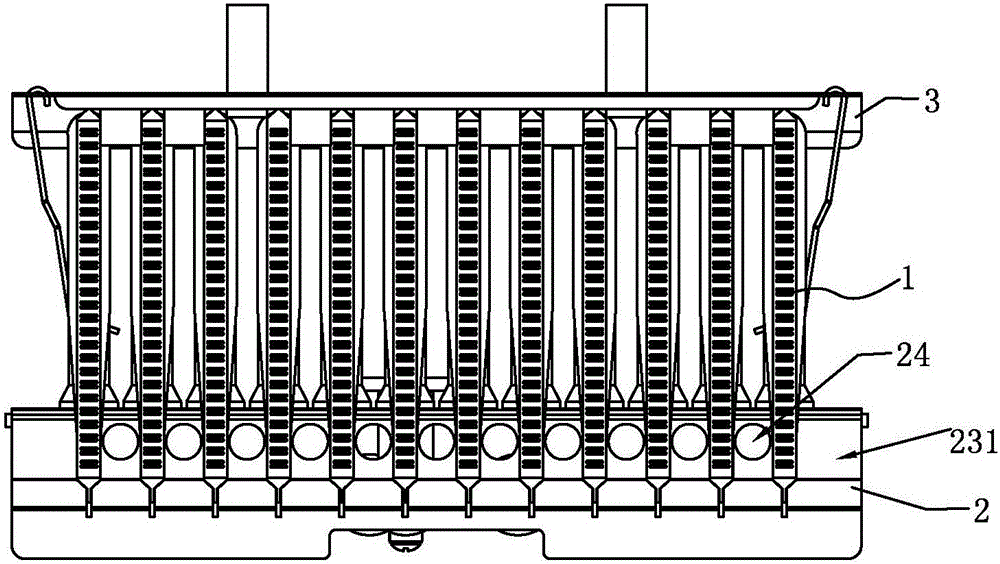

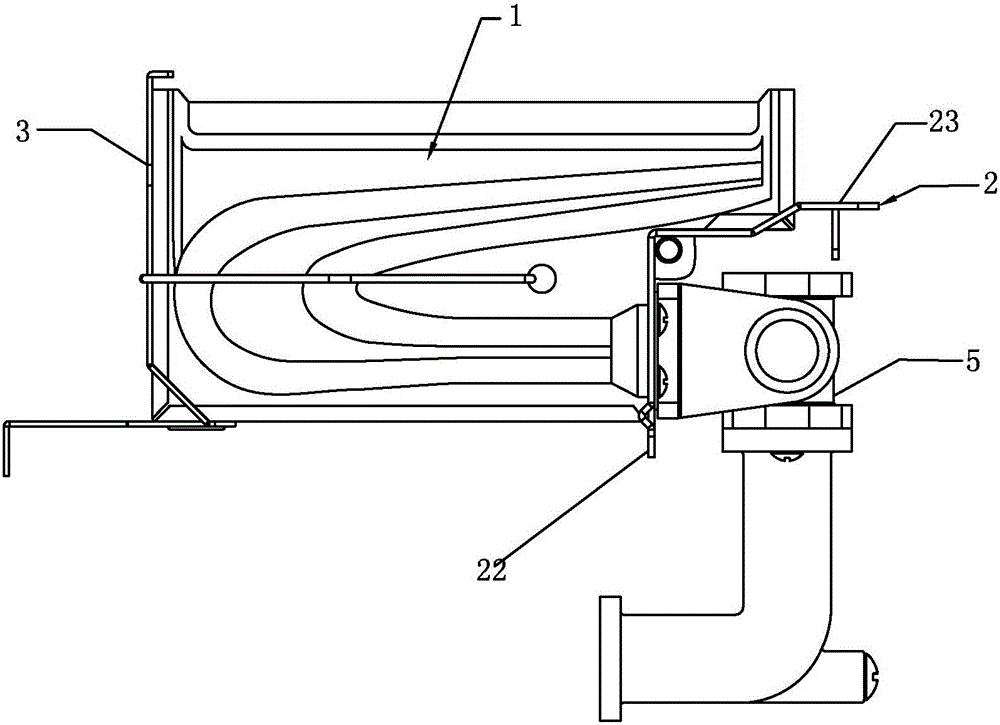

[0022] Such as figure 1 , figure 2 , image 3 As shown, a combustion assembly of a gas water heater includes a fire row 1, a front row bracket 2, a rear row bracket 3, a nozzle 4 and a gas distribution rod 5, and several fire rows 1 are arranged at a certain distance to form a burner; the front row bracket Air guide hole 21 is arranged on 2, and the front end of burner is arranged on the front row support 2, and the rear end is arranged on the rear row support 3, and the intake end of the ejection pipe 1A of fire row 1 is docked with air guide hole 21.

[0023] The front row bracket 2 includes a vertical shelf 22 and a horizontal shelf 23,

[0024] The air guide hole 21 is arranged on the vertical shelf plate 22, and the air guide hole 24 is arranged on the horizontal shelf plate 23, and the air guide hole 24 and the air guide hole 21 are spaced apart;

[0025] It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com