Self-washing type sand setting prevention small-displacement oil pump

A small displacement, oil pumping technology, applied in the direction of variable capacity pump components, pumps, pump components, etc., can solve the problems of sand guidance, eccentric wear, etc., to reduce valve cover breakage, sand and resistance. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

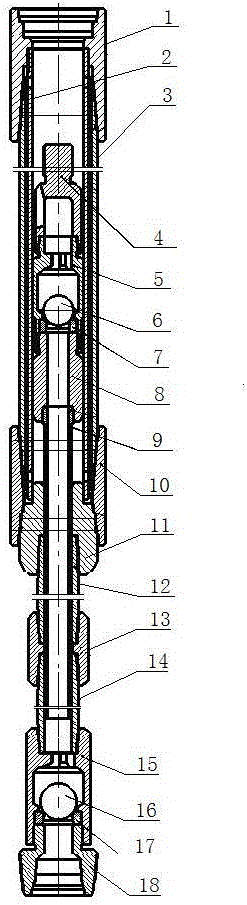

[0021] Below in conjunction with accompanying drawing, the present invention will be further described:

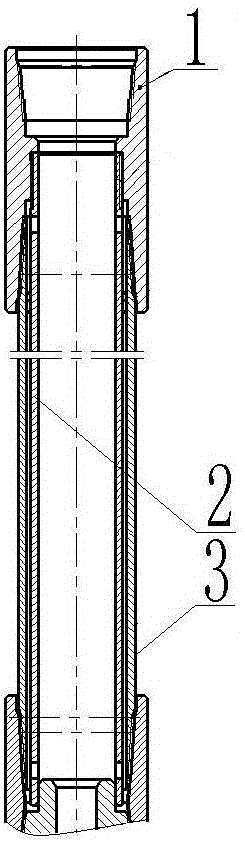

[0022] Such as figure 1 As shown, this self-washing anti-settling small displacement oil well pump includes guide spoiler assembly, plunger assembly, pump barrel assembly, refer to figure 2 , the guide spoiler assembly is mainly composed of the pump barrel collar 1, the righting guide rail 2 and the guide tube 3. Both the righting guide rail 2 and the guide tube 3 are threadedly connected with the pump barrel collar 1 at their respective upper ports, and both the righting guide rail 2 and the guide tube 3 are threadedly connected with the pump barrel assembly at their respective lower ports, and the pump barrel assembly There is a fixed valve in the lower part.

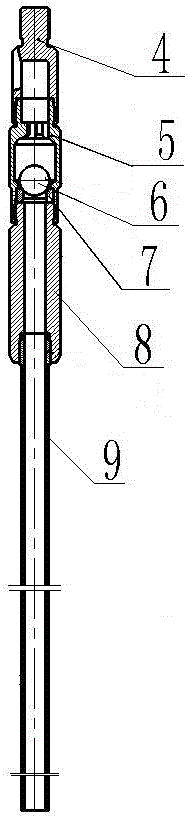

[0023] refer to image 3 , the plunger assembly consists of a plunger open valve cover 4, a plunger closed valve cover 5, a floating valve ball 6, a floating valve seat 7, a guide centralizer 8 and a hollow pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com