Gas turbine cooling reuse system combined with evaporative cooling and absorption refrigeration

An absorption refrigeration and evaporative cooling technology, which is applied in the direction of refrigerators, engine cooling, engine components, etc., can solve the problems of the decrease of the rated power generation capacity of the gas turbine, the decrease of the power generation of the gas turbine, and the increase of the power consumption of the compressor. The risk of fouling, the effect of improving power generation and efficiency, and reducing load consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

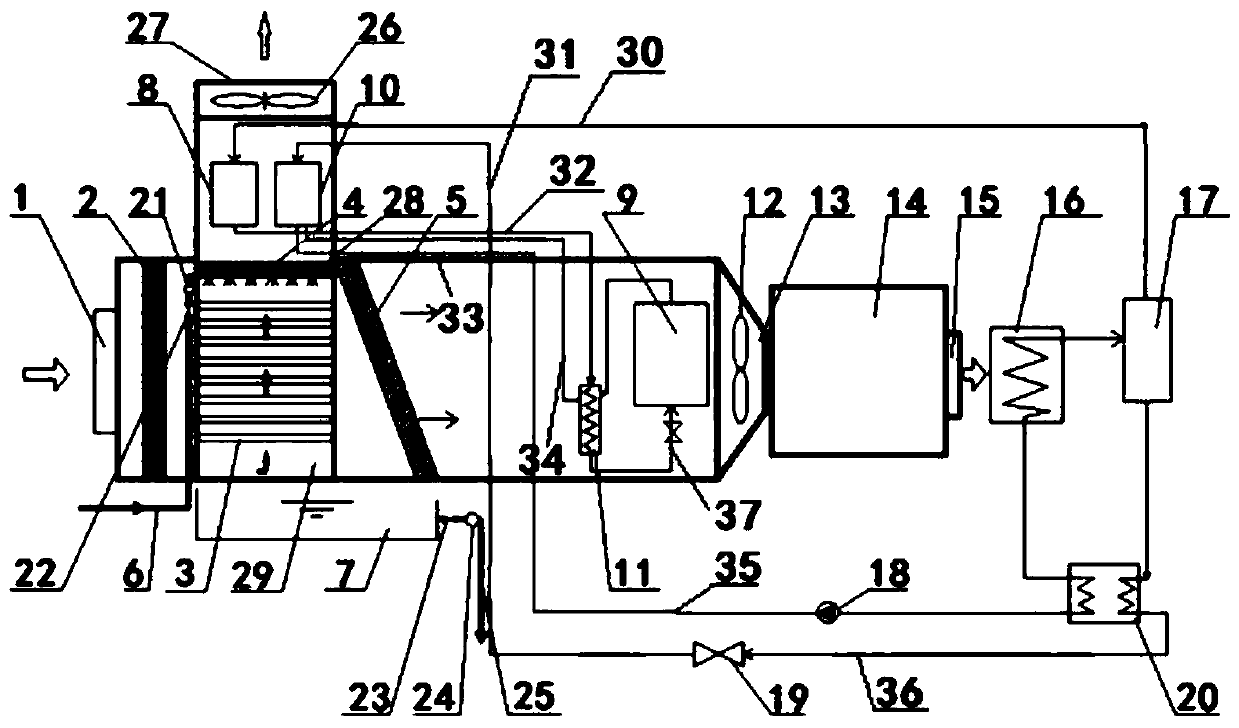

[0026] The gas turbine cooling and reuse system combined with evaporative cooling and absorption refrigeration of the present invention has a structure such as figure 1 As shown, it includes an evaporative cooling-absorption refrigeration composite air intake cooling unit and an external water tank 7; the air supply port 13 of the evaporative cooling-absorption refrigeration composite air intake cooling unit is connected with the air inlet of the gas turbine 14, and the exhaust of the gas turbine 14 The gas port 15 is provided with a generator 16, and the generator 16 is sequentially connected with the gas-liquid separator 17 and the solution heat exchanger 20 to form a closed circuit to form a gas-liquid treatment system; the evaporative cooling-absorption refrigeration composite inlet cooling unit and Gas-liquid handling system connection. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com