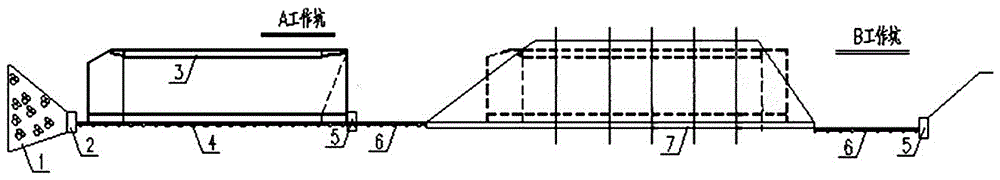

Double-L type pipe-roofing structure control box bridge jacking method

A technology for structural control and frame-constructed bridges, which is applied to underwater structures, infrastructure engineering, bridges, etc., and can solve problems such as uneven operation of railway lines, large soft soil foundations, and entanglements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In order to further illustrate the present invention, each step of the present invention is described in detail through the following examples.

[0034] The following is a construction embodiment of a 2-12m frame bridge of the present invention passing through the Shenyang-Dalian railway line (5-strand line):

[0035] The axis of the frame bridge is 41.50 meters long, the axis of the bridge is perpendicular to the railway line, and there are 5 railway lines at the jacking point. The net width of the frame bridge is 2-12m, the overall width of the vertical section is 26.6m, and the bridge height is 7.57m. The base of the frame bridge is located on the silty clay layer with a basic bearing capacity of 115kPa. The groundwater level is relatively high, and the arrangement of the drainage well is difficult. In addition, the structural axis is long, and it is easy to cause large piers and excessively large skylights during jacking. Therefore, before the jacking operation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com