Biodegradable thermoplastic starch resin film and preparation method thereof

A thermoplastic starch and biodegradation technology, applied in the field of biodegradable thermoplastic starch resin film and its preparation, can solve the problems of environmental pollution, affect the balance of ecology, and be difficult to degrade, and achieve the effects of avoiding environmental pollution and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

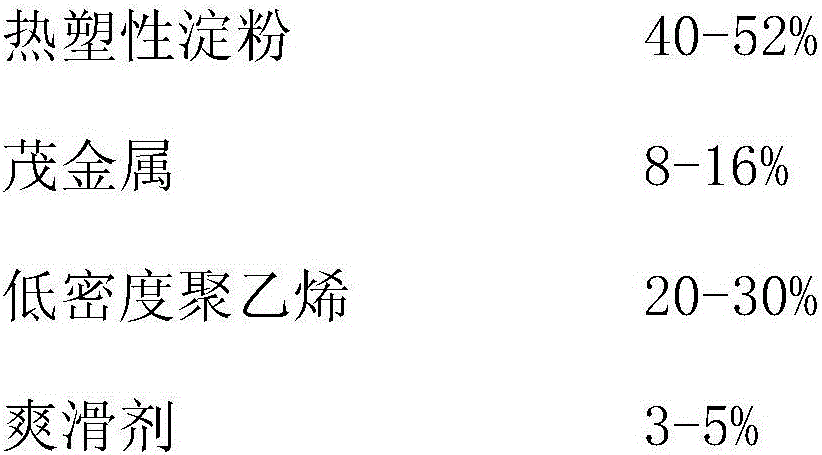

[0013] A biodegradable thermoplastic starch resin film, calculated by mass percentage, the composition and content of its raw materials are as follows:

[0014]

Embodiment 2

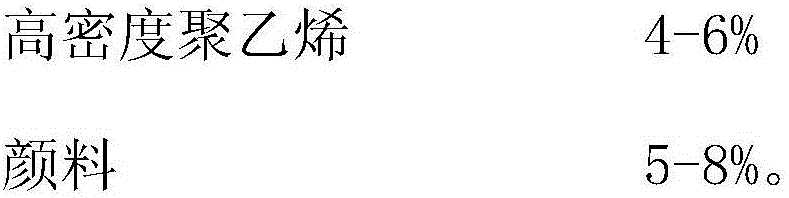

[0016] A biodegradable thermoplastic starch resin film, calculated by mass percentage, the composition and content of its raw materials are as follows:

[0017]

Embodiment 3

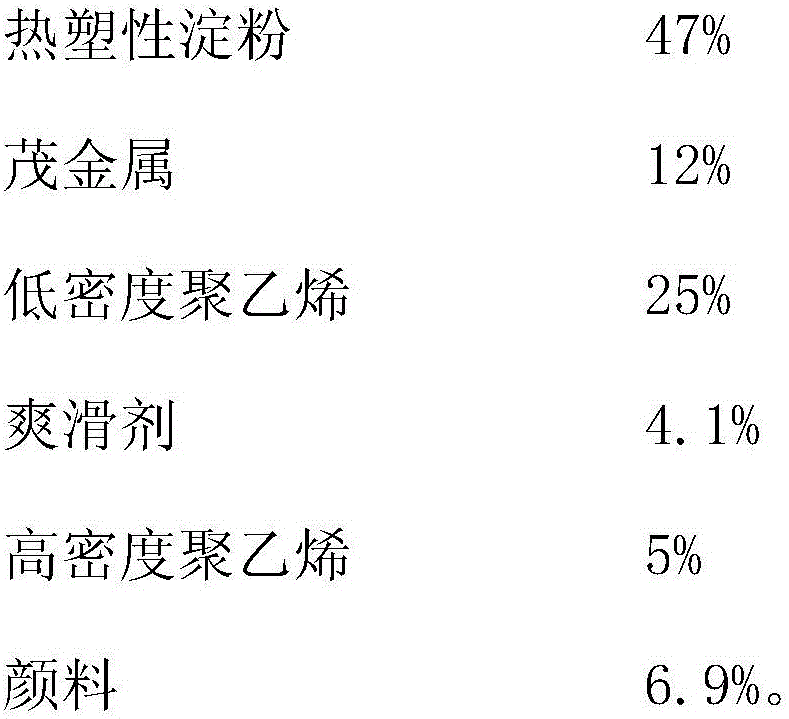

[0019] A biodegradable thermoplastic starch resin film, calculated by mass percentage, the composition and content of its raw materials are as follows:

[0020]

[0021]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com