Heat pump treatment system of sewage treatment circular aeration tank

A sewage treatment and treatment system technology, applied in water aeration, water/sludge/sewage treatment, aerobic process treatment, etc., can solve the problems of increasing the amount of odorous gas, affecting the survival of microorganisms, and increasing the temperature of sewage. To achieve the effect of reducing the generation of odorous gas and saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in combination with specific embodiments.

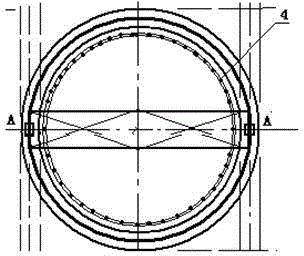

[0016] The invention relates to a sewage treatment circular aeration tank heat pump treatment system, comprising a cylindrical base 1, an annular slide rail 3 is arranged on the top edge of the base 1, and a radial bracket 5 is arranged above the slide rail 3, the bracket 5 The bottoms of both ends are provided with rollers 2, and the rollers 2 move circularly along the slide rail 3. The bottom surface of the roller 2 is provided with a groove, and the slide rail 3 is embedded in the groove on the bottom surface of the roller 2 . A radiator 4 is arranged around the inner wall of the base 1, and the radiator 4 is a metal coil.

[0017] An aeration tank is arranged above the support 5, and the aeration tank rotates on the support 5, and the heat generated by the aeration is transferred to the radiator 4, and the radiator 4 transfers the heat or is used for heating the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com