Garbage automatic packing method and garbage automatic packing machine

A garbage and automatic technology, applied in packaging and other directions, can solve the problems of difficult to control heating temperature and time, reduce the success rate of sealing, and seal disconnection, and achieve the effects of high cost performance, low cost and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

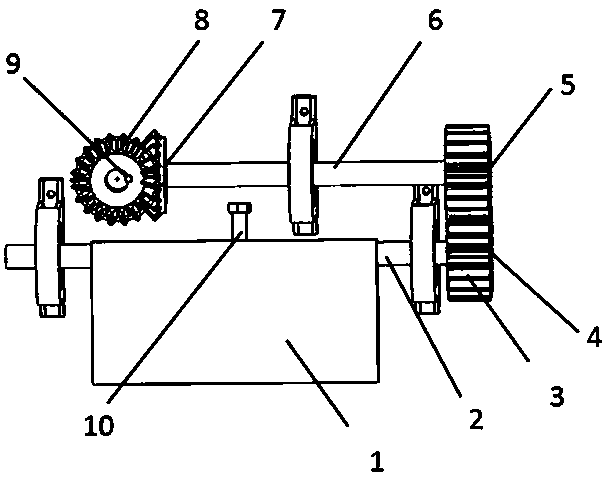

[0055] The type of motor that can be selected for the automatic garbage baler is: stepping motor, model 42BYGH47-401A. Its dimensions are: current 1.5A, torque 0.55N·m, driving voltage 24VDC, step accuracy 5%. Its matching driver current is 0.3-3A, voltage is 10-36V, and there are 4 subdivision modes.

[0056] The battery unit directly provides energy consumption requirements for the alarm unit and the speed control unit. The type of battery pack that can be selected for the garbage automatic baler described in this paper is: lithium battery, model HX-M-N01. Its size is , and its weight is about 170g, capacity 2000mAh, output voltage, discharge time at 0.2C current not less than 6h, charging voltage 12.6V, working time for one year.

[0057] The infrared sensor can choose Yunhui (A3J1) LHI778 pyroelectric infrared sensor.

[0058] The buzzer and the single-chip microcomputer can use the single-chip microcomputer and the 5V buzzer in the single-chip microcomputer development ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com