Valve pin decoupling of hot runner synchronization plate

A technology of synchronous plate and valve pin, applied in the field of valve pin decoupling device, can solve the problems of large axial installation space, difficult service, unreliable decoupling valve pin, etc., and achieve the effect of small axial structure size and simple effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

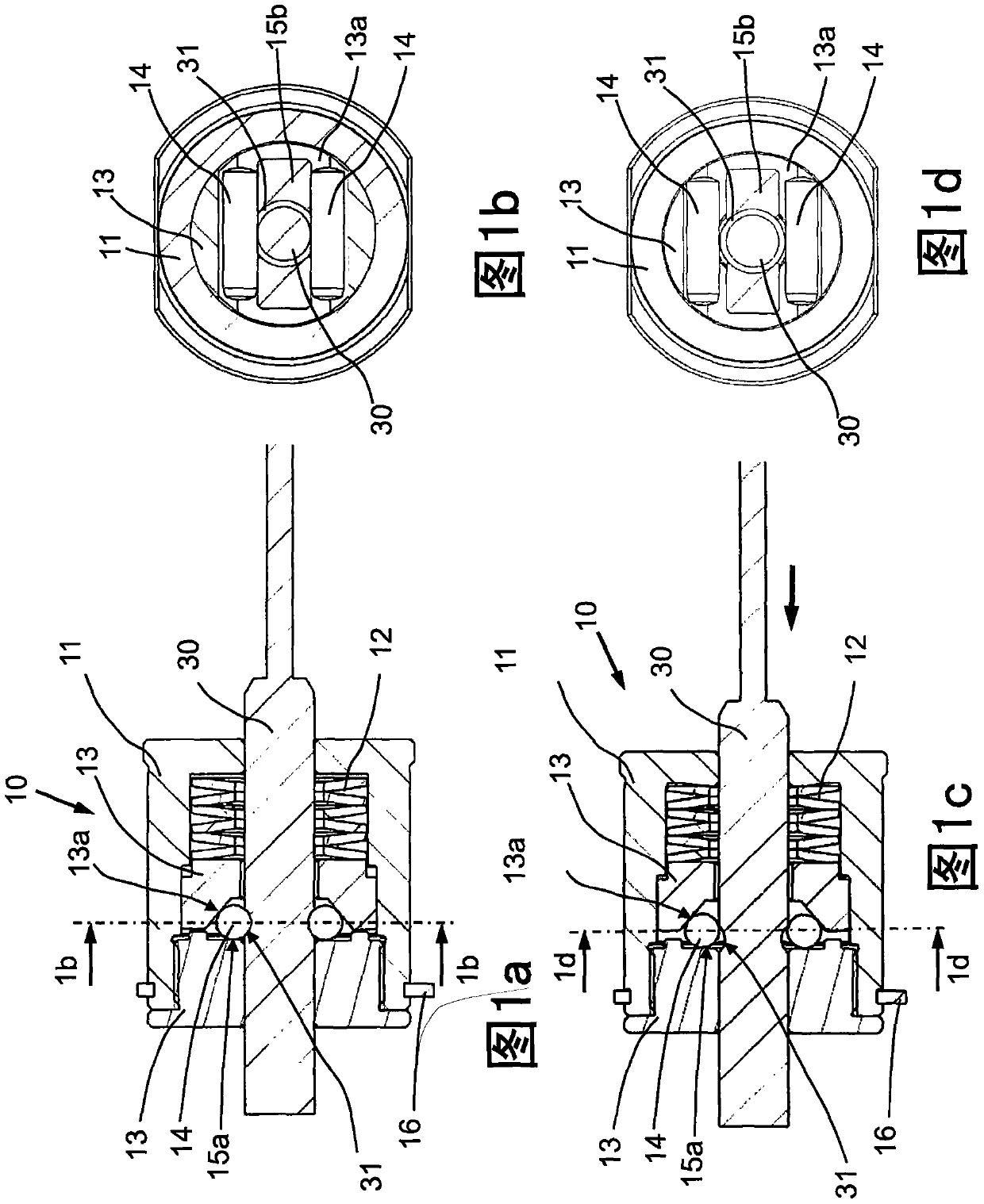

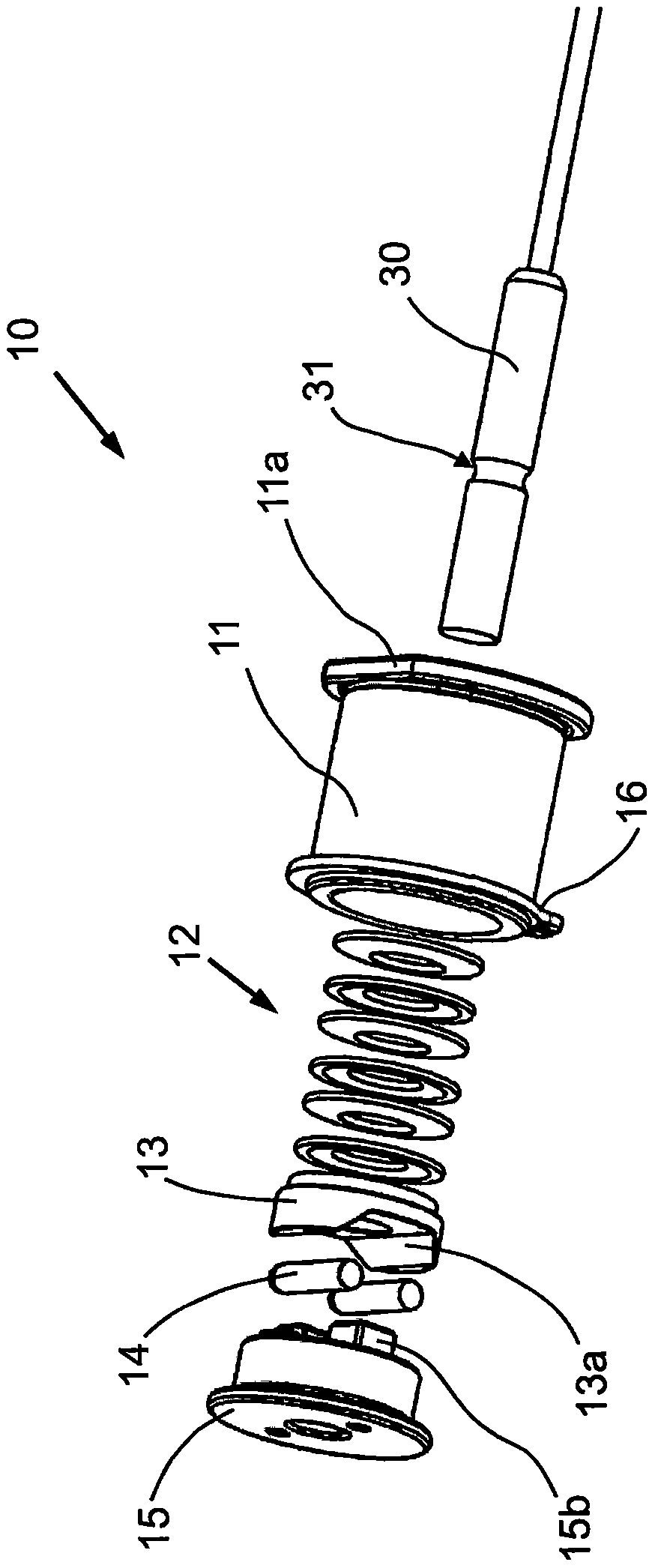

[0043] Figure 1a It is a cross-sectional view showing the valve pin decoupling device 10 in the coupled state of the exemplary embodiment of the present invention. The valve pin decoupling device 10 comprises a sleeve 11 which supports a valve pin 30 . Arranged in the sleeve 11 is biasing means 12 which in the exemplary embodiment is realized by a coil spring assembly. Furthermore, a thrust element 13 is arranged in the sleeve 11 and a biasing means 12 applies a force to the thrust element. The exemplary valve pin 30 includes a peripheral retaining groove 31 in which the two retaining elements 14 are received.

[0044] A cover 15 is arranged on the end of the sleeve 11, said cover being opposite to the biasing means 12; the cover 15 is fixedly screwed onto the sleeve. In the installed state of the valve pin decoupling device 10, the cover 15 is thus arranged on the side of the synchronizing plate facing away from the mold cavity (on Figure 6a shown in ). The cover 15 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com