Tailstock mechanism of extrusion tap grinding machine

A technology for extruding taps and grinding machines, which is applied to the parts of grinding machine tools, grinding/polishing equipment, metal processing equipment, etc., which can solve the unfavorable batch production of the whole machine, high requirements for installers, and loss of installation cycle, etc. problems, to achieve the effect of easy promotion and use, easy installation and adjustment, and high working reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

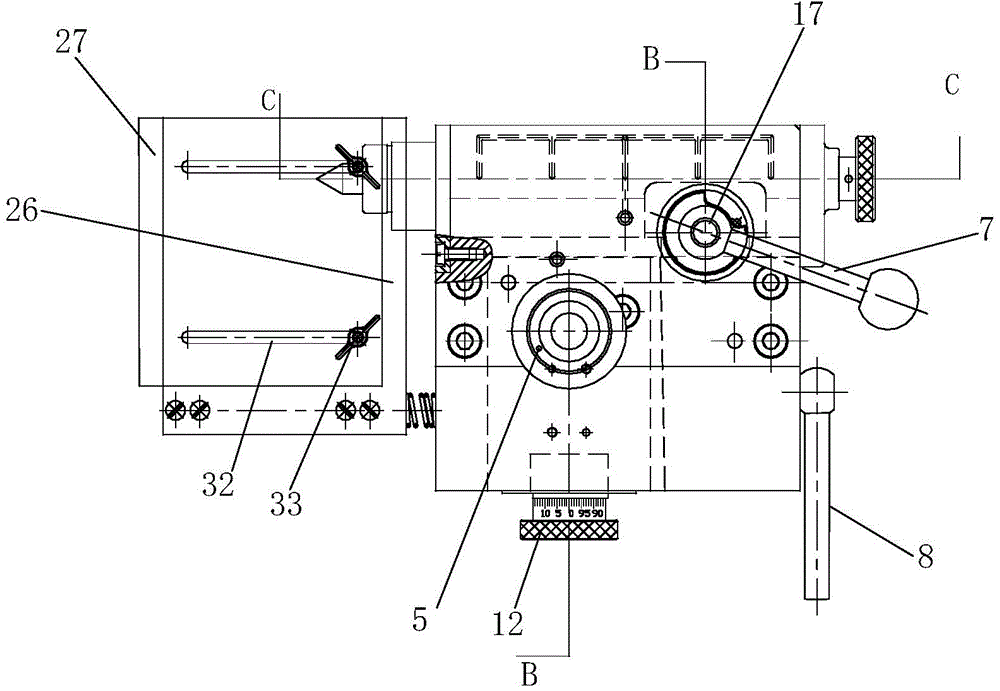

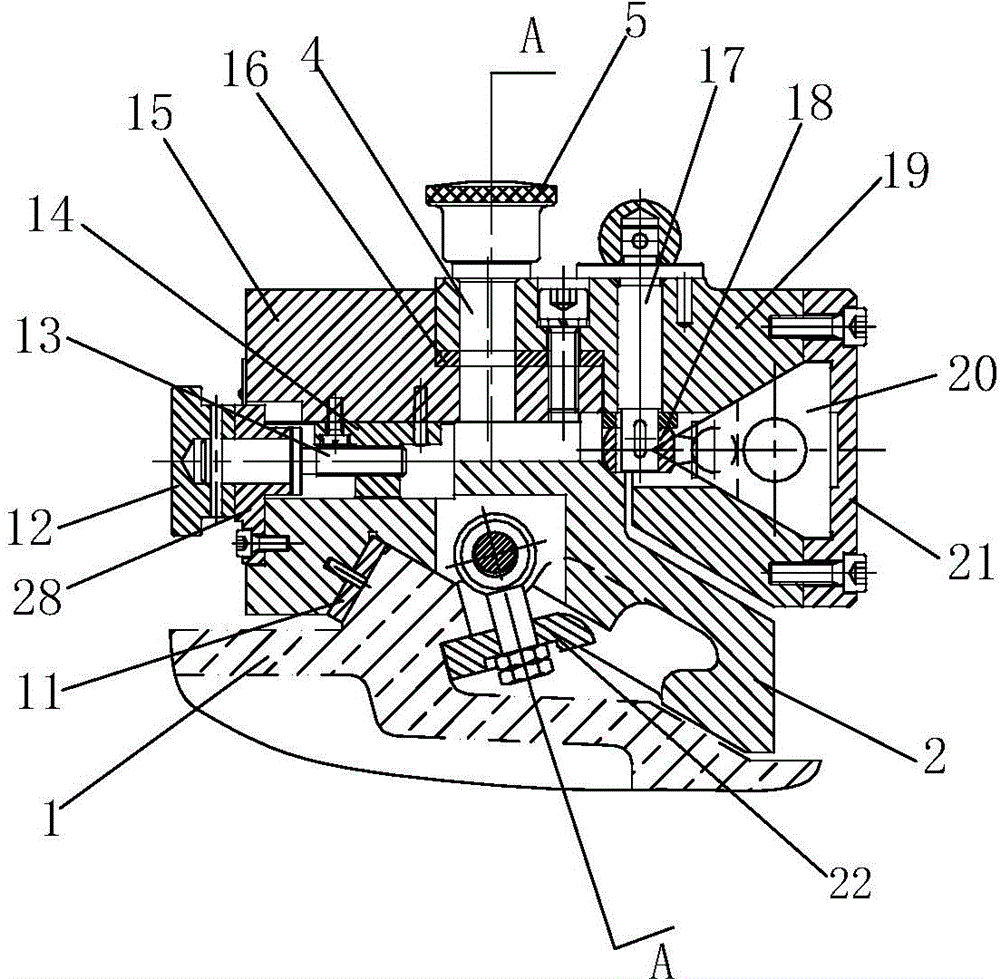

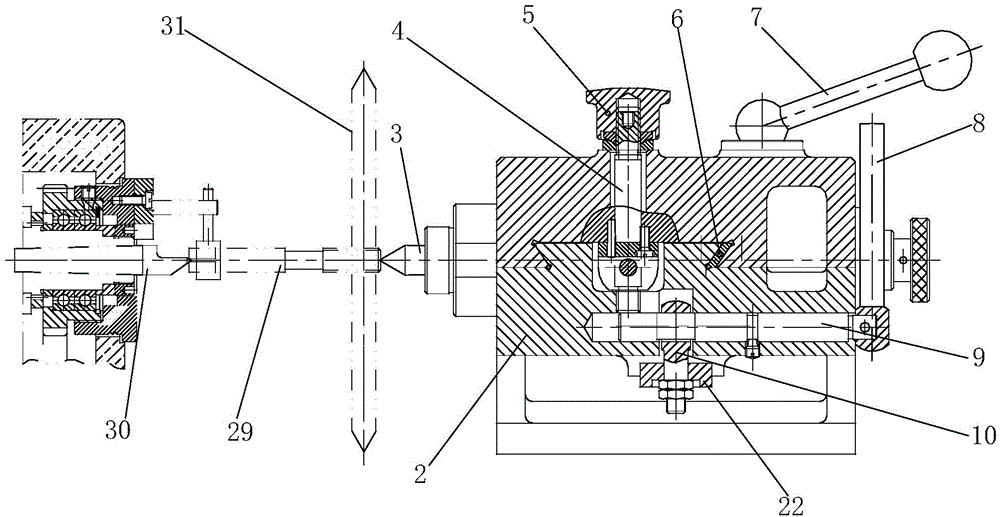

[0042] Such as figure 1 , figure 2 and image 3 The shown tailstock mechanism of an extrusion tap grinder includes a lower seat 2 installed on the workbench 1 and an upper slider left block 15 arranged on the lower seat 2 and the left block of the upper slider 15 is connected with the right block 19 of the upper slide seat, the slide seat 2 is provided with an eccentric shaft 9, and one end of the eccentric shaft 9 is provided with a locking handle 8 for driving the eccentric shaft 9 to rotate, and the eccentric shaft 9 The other end of the pull rod 10 is installed, the pull rod 10 is connected with a pressure block 22 for locking and connecting with the guide rail on the workbench 1, and the left block 15 of the upper slide seat and the lower seat 2 are provided for The left and right adjustment mechanism that drives the left block 15 of the upper slide and the right block 19 of the upper slide to move left and right as a whole, the left block 15 of the upper slide is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com