Mesopore feeding process of thick and large part in turbine shell casting turbine chamber

A technology of turbine chamber and turbine shell, applied in the direction of casting mold, casting mold composition, manufacturing tools, etc., can solve the problems of long feeding distance, shrinkage and porosity of thick and large turbine chamber, and product quality not reaching a higher level, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

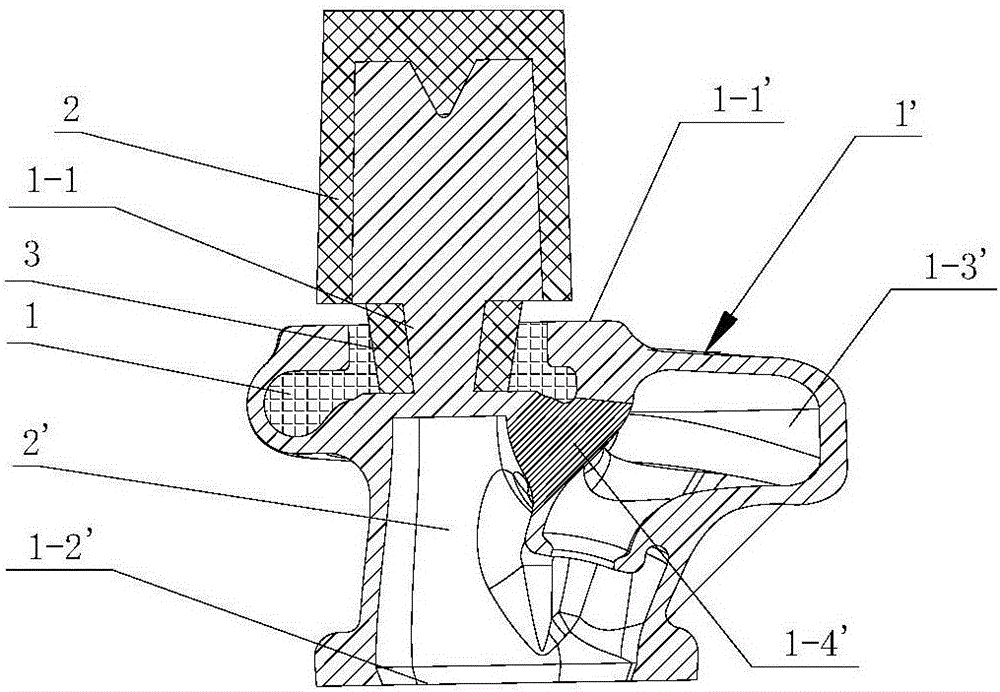

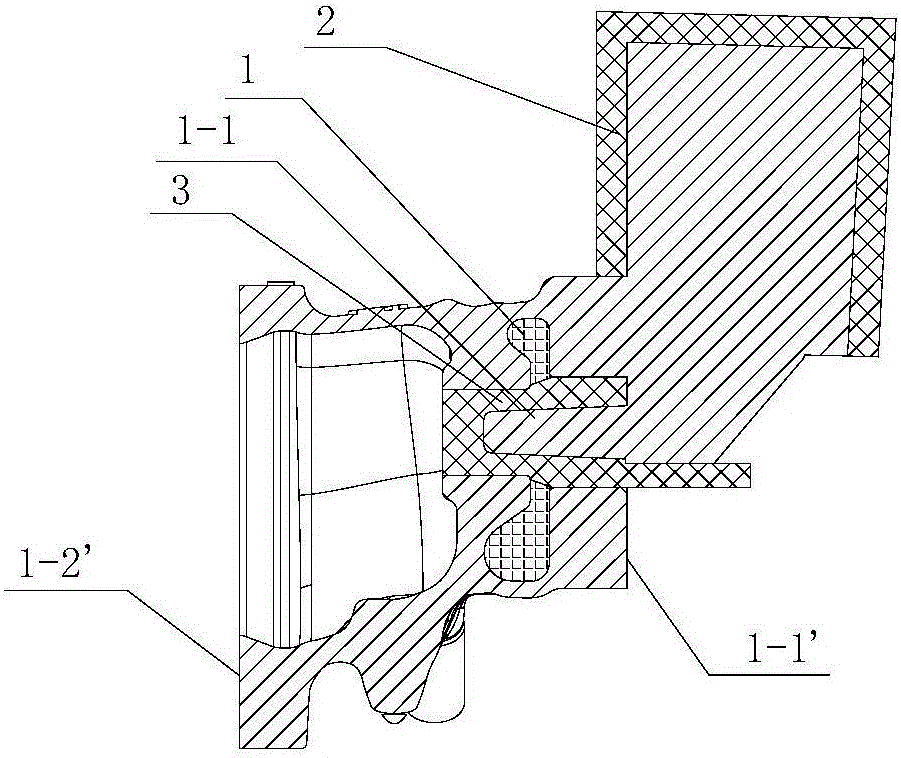

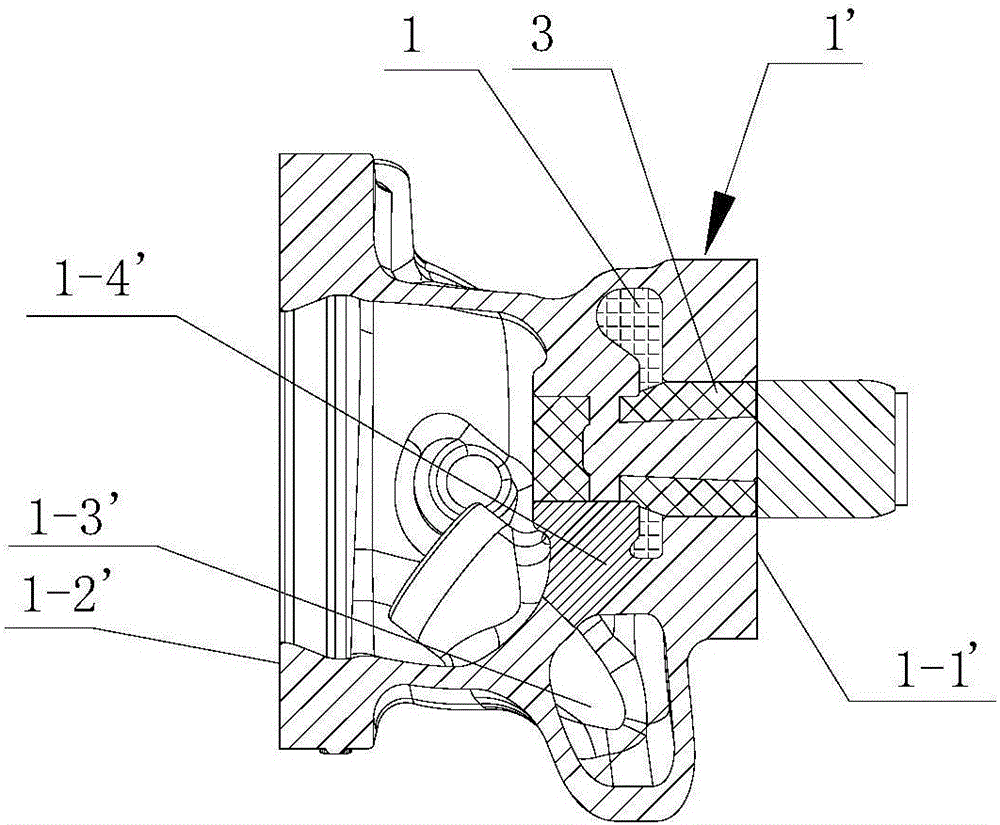

[0020] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0021] See Figure 1-3 , the medium-hole feeding process for the thick and large part of the turbine chamber of the turbine shell casting, including a sand core 1 arranged in the mold corresponding to the turbine chamber to be cast, and a feeding channel 1-1 is set on the sand core, said One end of the feeding channel extends to a position connected to the thick part 1-4' in the turbine chamber to be cast, and the other end of the feeding channel extends to the end of the turbine shell casting 1' to be casted and connected to the intermediate body. Outside the flange port 1-1', a riser 2 is provided at a position corresponding to the feeding channel outside the flange port.

[0022] In the above-mentioned mesopore feeding process, the feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com