Joint structure for multipurpose steam producing device

A production device and joint structure technology, applied in applications, household appliances, carpet cleaning, etc., can solve problems such as installation difficulties, inconvenient use, and difficult separation, and achieve the effects of convenient use, simple joint structure, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

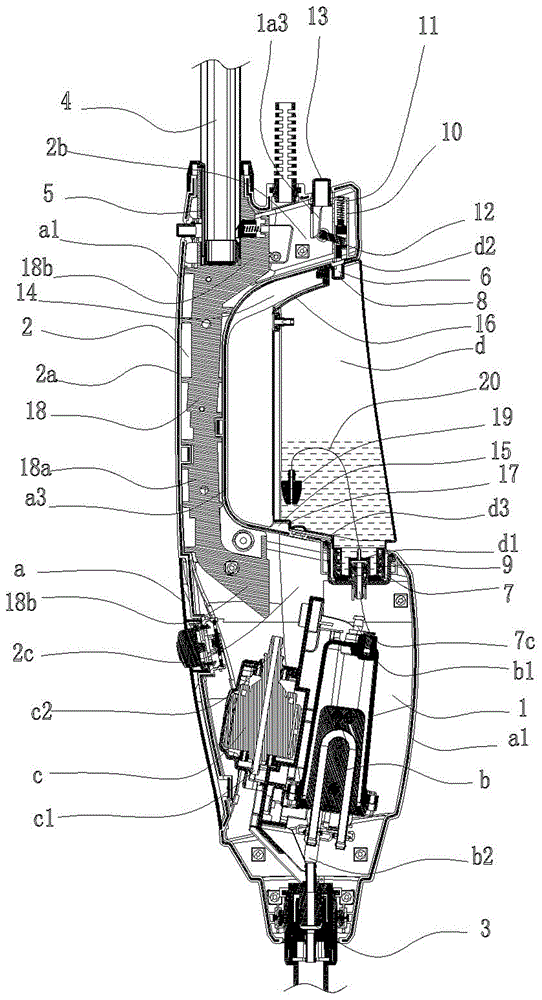

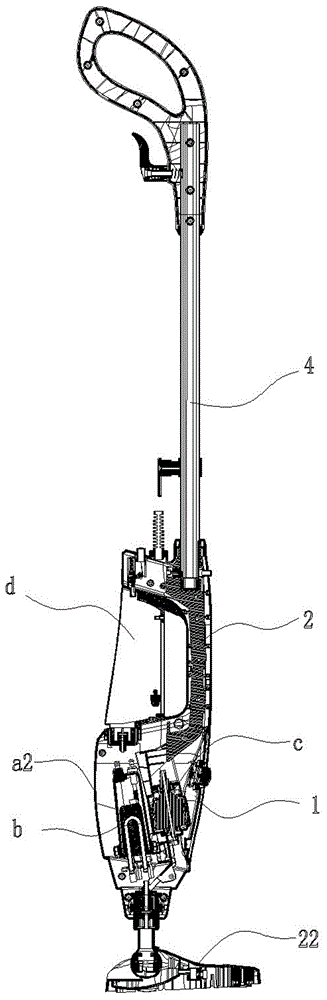

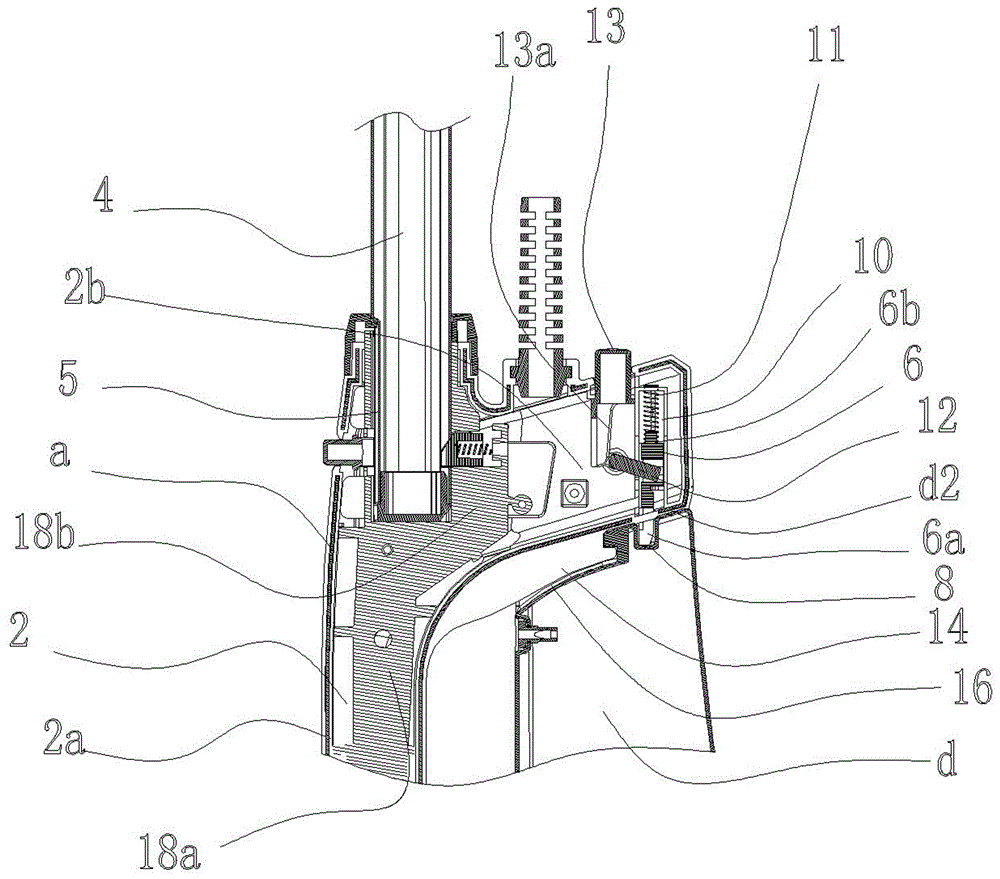

[0014] Such as figure 1 As shown, the steam production device on the steam mop of the present invention includes a housing a, a steam generator b arranged in the housing a, a water pump c, a water container d, the water outlet c1 of the water pump c and the steam generator b The water inlet b1 is connected, and the lower end of the steam generator is provided with a joint 3 that communicates with the steam outlet b2 of the steam generator b. The joint 3 includes an inlet e, a set The insertion port f on the steam ejection device (steam floor mop member 22), the inlet e includes a sleeve e1 fixed on the end of the steam production device, a steam generator fixed in the sleeve e1 and the steam production device The steam intubation e2 connected to the steam outlet b2 of the device b, the sealing ring e3 sleeved on the outer wall of the steam intubation e2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com