Connector and manufacture method thereof

A connector and elastic connection technology, which is applied in the direction of connection, fixed connection, contact piece manufacturing, etc., can solve the problems of high total cost, cost waste, low material utilization rate, etc., and achieve convenient processing, reduce production cost, and connector structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate the understanding of those skilled in the art, the present invention will be described in detail below with reference to the drawings and embodiments.

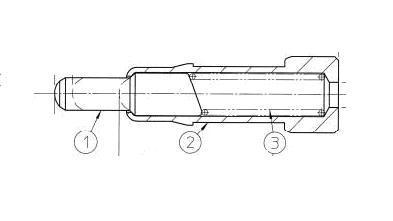

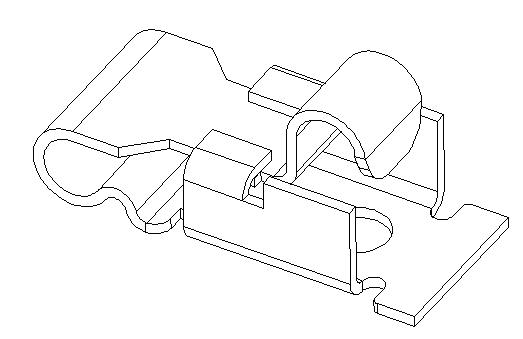

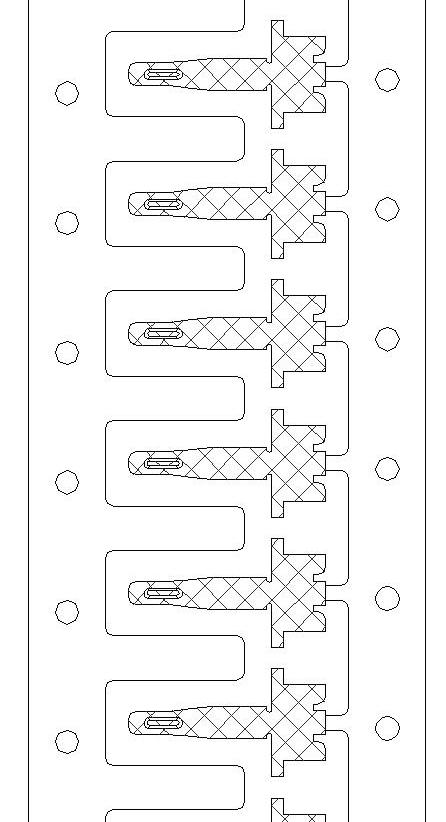

[0022] Such as figure 1 As shown, the connector disclosed by the present invention is in the form of a horizontal U-shape as a whole, and the lower arm of the U-shape is longer than the upper arm. The lower arm is bent upwards and inwards from the end to form an arched support part 10. The arched support part 10 is approximately an isosceles triangle, and the corners between the two waists are arcs to avoid sharp scratches; the end of the upper arm The elastic connection part 20 corresponding to the support part 10 is formed by arching from the bottom to the top, and the elastic connection part 20 is provided with a protrusion 21 for contacting the connected part. When in use, the elastic connecting part 20 is compressed, and with the help of the elasticity generated at the rear part, it will be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com