Winding machine for making cotton laps and method for winding fiber strips

A technology of winding machine and fiber tape, which is applied in the field of winding fiber tape, can solve the problems of high energy consumption and high energy cost, and achieve the effect of reducing the winding speed and reducing the formation of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

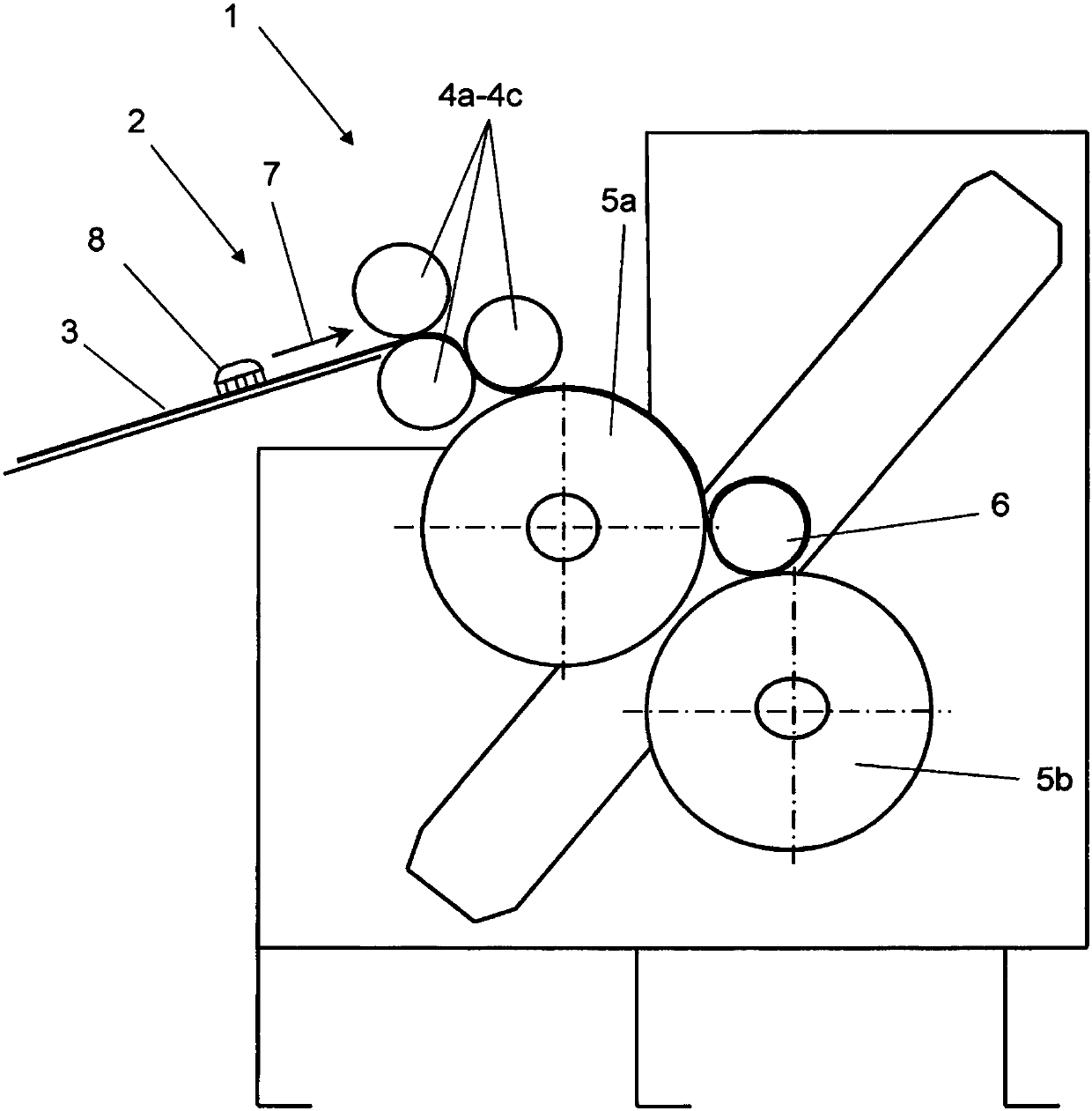

[0031] exist figure 1 The winder 1 is shown in the textile industry, for example in woolen combing preparation How to use in . A plurality of fiber strips 3 , which may be made of natural or man-made fibers, are transported through the cans of the winder 1 and level dyed in a drafting device (not shown). The fiber strip 3 is further guided through the feed-in area 2 to a plurality of press rolls 4a-4c, which guide the fiber strip 3 between the two winding rolls 5a, 5b and the winding sleeve 6 for producing the lap. in the pull-in area between them. A pre-compressor 8 is arranged in or on the feed area 2 , which level dyes the fiber web 3 . Not shown are the table calenders arranged in the feed area, the drafting devices arranged upstream of the table calenders, and the creels (gatters) arranged upstream of the winders. The winding pressure passes through the figure 1 The laterally arranged air cylinders, not shown in FIG.

[0032]As an alternative to the embodiment with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com